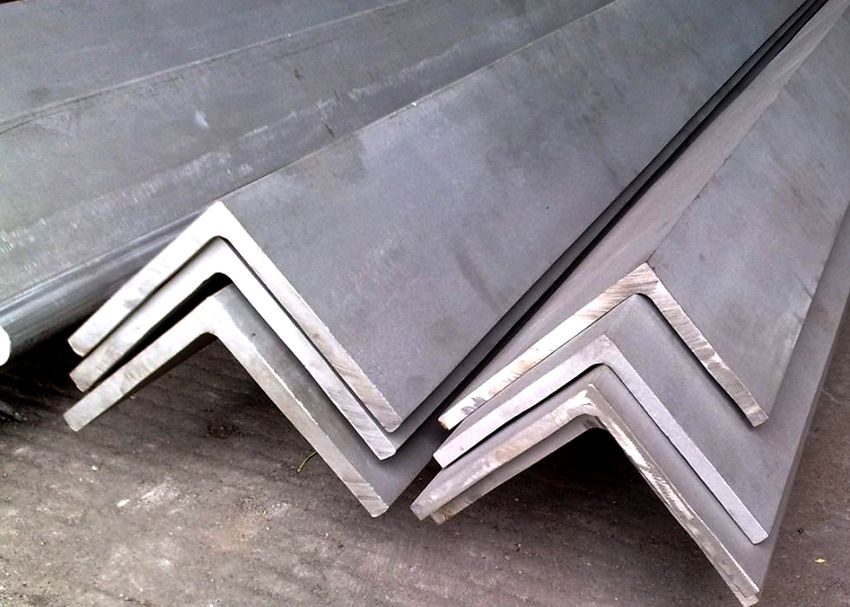

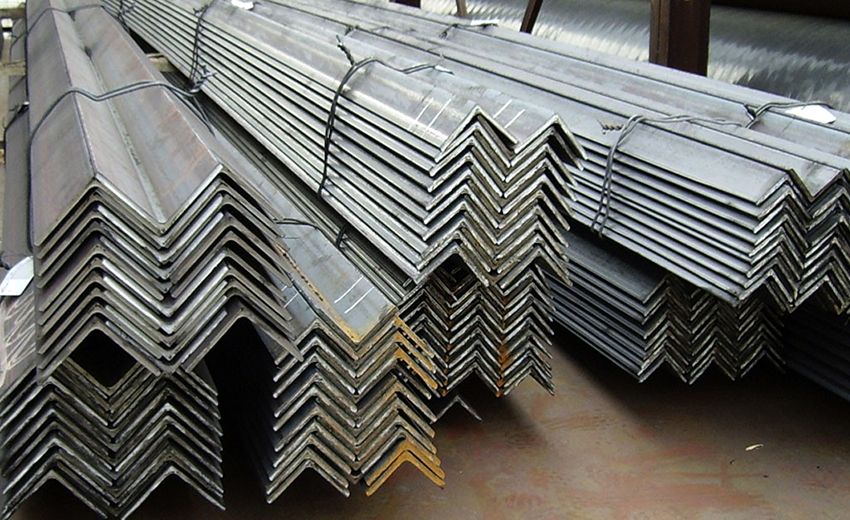

Steel corner is one of the most common types of rolled metal. Before construction, regardless of its volume, as well as when ordering these products there is a need to determine the weight of the party. To date, there are several ways to calculate the weight of the corner. The mass of the product depends on its type and thickness of the sides.

Varieties of steel angles and their features

Corners made of steel are classified according to the width of the sides. According to this indicator, all the details are divided into two types: equal shelf and unequal. In the first case, the product has the same sides, and in the second, one of the sides prevails in width.

The weight of steel corners is a necessary parameter for carrying out construction and transport calculations. This indicator is influenced by many factors. First of all, the mass of parts belonging to this group of metal, depends on the dimensions of the products. As well as a great influence on the amount of weight has a way that was applied in the production of these parts.

Note! All products of this type are performed in two ways. The first of these involves rolling primary blanks through special shafts that form the part. This method is called hot-rolled, since before the beginning of the molding the product is heated to the required temperature. The second method of making steel corners is flexible. To implement it, special profile-bending equipment is used.

In order to determine the weight of the metal angle, you must first find the mass of 1 meter of the product. This calculation is performed using two indicators: the cross-sectional area and specific gravity. These values need to be multiplied. Each of the sizes of steel parts has its own specific mass, which is determined in different ways. Another common method of finding this parameter is with the help of special tables, which can be found in the corresponding State Standards.

The last way to quickly determine the mass of 1 p. m steel parts (for example, the weight of the angle 75h75h6 mm) – online calculator. This is a special program that performs the calculation according to the formula entered into its code. To determine the required value, you need to enter the data in the appropriate cells – and the online calculator will perform the calculation itself.

Manufacturers engaged in the release of this type of metal, must comply with the requirements and standards prescribed in the relevant State Standards. It is important to note that the tables, which can be found in the regulatory documentation, indicate the theoretical mass of 1 p. m details. In turn, the calculated weight is a quantity that is almost impossible to obtain.

To find the actual weight of the product, there is only one way – weighing, which is not very convenient. The most common type of product has two sides, the width of which is 50 mm. The weight of the corner 50x50x4 per meter can be calculated independently or use a special program for this.

It should also be understood that the averaged density values of the metal are used for the calculations. For products made of steel, a constant value is applied, which is 7850 kg / m ?. However, currently there are many steel grades, each of which has an individual density index that differs from the others. Thus, the calculation of the weight of a batch of corners is made using average values, which is reflected in the final figure.

In addition, steel corners can have a different class of accuracy (A, B, C). Allowable discrepancies with accepted dimensions specified in GOST, also have an impact on the calculation of mass. From this follows this conclusion: the regulatory documentation contains information on the specific gravity, which, as a rule, does not correspond to the actual. However, GOST standards are based on all the necessary calculations. Manufacturers are also guided by this documentation.

Independent calculation is often necessary when installing various fences and frame structures with your own hands. In this case, a special place is given to the product, which has the following geometrical parameters: 50, 50, 5. It is recommended to look for the weight of a corner of this type using the tables that are specified in the regulatory documentation.

Useful information! Production of steel corners takes into account the percentage of marriage, which in any case is formed in the manufacturing process. Unscrupulous manufacturers specifically reduce wall thickness, making the product more susceptible to stress. In the case of purchasing low-quality products and during its calculation, the final figure will be very different from the actual mass of the product. Especially it concerns the calculations of large lots.

How to independently determine the weight of a corner of 50 mm and other varieties of the product?

The exact weight of a steel product of this type can only be determined by weighing. However, this method is not always convenient. To find the estimated mass of the party of corners, you must first calculate the weight of 1 meter. The easiest way is to use special tables that contain data on all standard sizes of steel products of this type. First of all, you need to measure the width of the sides (shelves). And it is also necessary to determine the thickness of the same sides.

Using the above data, you can easily find the size you are interested in in the table and see the weight of 1 running meter. m products (for example, the weight of the area 50×50 mm). Then it is required to divide the obtained theoretical mass by the density of steel, the average value of which is 7850 kg / m ?. The next step is to multiply the result by the density of the steel grade.

If necessary, you can carry out an independent calculation in full. However, such a calculation may be inaccurate, since it does not take into account the rounding radii between the sides. The process of self-calculation of the weight of the corner of 63 mm (or any other) consists of several stages.

The first step is to determine the cross-sectional area of the part. To do this, you will need to measure the length of one side (shelf) and multiply the resulting figure by the thickness. Next, from the length of the second side, you must subtract the thickness of the product, after which the resulting number is multiplied by the thickness. This determines the cross-sectional area of one and the other side.

After calculating the area of the parties, you need to add these two indicators. The result is a total theoretical cross-sectional area of the steel angle. It remains only to multiply this value by the density and 1 m. Thus, the theoretical weight of 1 m of the steel part is determined.

The tabular method of determining the mass of 1 m of steel parts is the most popular. This is explained by the fact that these schemes contain ready data that were calculated specifically for the convenience of using values. Such tables can easily be found on the Internet. They are part of the regulatory documentation (GOST).

Note! For each type of steel metal there is a separate standard.

Such tables are used when you need to quickly determine the mass of a small or large batch of corners. In order to find the total weight, you need to take a value that corresponds to a mass of 1 p. m steel parts, and multiply this figure by the total footage. Thus, the decisive role is played by the weight of 1 meter of the corner. The table allows you to find this theoretical value without wasting time and energy. Such schemes allow reverse calculation. For example, if a person knows the mass of a batch of steel corners, then using this data you can determine the total length of all products.

Weight table 1 p. m steel corners with different sizes:

| Dimensions, mm | The specific gravity of 1 st. m (kg) |

| 40x40x3 | 1,846 |

| 50x50x6 | 4,467 |

| 63x63x4 | 3,896 |

| 70x70x7 | 7.392 |

| 75x75x7 | 7,964 |

| 100x100x10 | 15.1 |

| 40x40x4 | 2.419 |

| 50x50x5 | 3,769 |

| 70x70x8 | 8,373 |

| 50x50x3 | 2,324 |

| 40x40x5 | 2.976 |

| 70x70x5 | 5.382 |

| 50x50x7 | 5,150 |

| 75x75x9 | 10.07 |

| 63x63x5 | 4,814 |

| 100x100x7 | 10.76 |

| 63x63x6 | 5,717 |

| 100x100x12 | 17.9 |

GOST standards contain tables that indicate more data. This increases the accuracy of the calculation. For example, in the regulatory documentation you can find the proportion of different types of steel.

A special online calculator is programmed to find the weight of one product. After obtaining the desired value, the possibility of further calculations arises. Online calculator can be found on the Internet, using the browser search bar. This method allows you to quickly and accurately calculate the required weight of 50x50x4 mm corners and other popular types of rolled metal.

In order to perform the calculation, you will need to enter the dimensions of the part in the corresponding cells. It is necessary to know the length of the product, as well as the thickness of the shelves, the width of the corner and its height. For maximum accuracy, it is recommended to specify the steel grade from which the part is made.

This program performs an automatic calculation using a special formula. This equation has the following form: m =? * S * (A + B – S) * L, where:? – steel density indicator; S is the wall thickness; A and B – the size of the shelves; L is the length of the product.

Note! It is important to remember that the weight of an angle of 75, 50 mm (or any other) is a quantity that is primarily a reference. Thus, the online calculator first synchronizes with tables located in state standards, and only then calculates the desired parameter using a formula.

In most cases, the data being driven in can be easily found in special tables. Most often, the calculated mass of products that are very popular because of the many applications. If the calculator does not find the necessary parts in the table, then it is necessary to calculate by the formula.

How to calculate the weight of 1 meter of the corner 100x100x7 mm: instruction

Corners are made in accordance with the requirements of GOST. In the process of their production, possible deviations are taken into account, which are also spelled out in the relevant regulatory documentation. To calculate a corner with dimensions of 100x100x7 mm, the easiest way is to refer to the special table. In the GOST, regulating equal products, the mass of 1 m of this product is 10.79 kg.

It is important to remember that in order to correctly calculate the mass, it is necessary to accurately determine the thickness of the product walls, otherwise the final value will be incorrect. Parts with such dimensions may have a different thickness. For example, the weight of a 100x100x8 mm corner will be greater than that of a product whose thickness is 7 mm.

There are tables that contain information not only about the theoretical mass of 1 p. meters of products, but also about how many meters are contained in 1 ton of steel. Calculations in such tables are made taking into account the norms of state standards. The document regulating equilateral steel products – GOST 8509-93.

Steel metal, whose width of shelves is 100 mm and thickness – 8 mm, is very popular. The weight of 1 meter of the corner 100x100x8 is 12.25 kg.

Unequal products also have the appropriate standard documentation, which contains tables with all the necessary data. For greater accuracy, you can determine the mass on your own, using the appropriate formula. The equation in this case is as follows: py = [(A + B – t) * t + (1 -? / 4) * (r? Internal – 2 * r? External)] *?, Where: t is the thickness index the parties; A – shelf width (large); B – shelf width (small); ? – steel density; r inner is the radius of the inner rounding of the sides; r outer is the radius of the outer rounding.

When using the formula it is recommended to check the accuracy of calculations several times. This is due to the fact that in self-computation, errors in numbers are often made.

Standard sizes of these products are spelled out in GOST, however, the manufacture of ideal products, in accordance with these standards, is a rather complicated process. As a rule, the finished products have certain errors. It is important that the deviation from the ideal size be within the limits specified in the state standards.

The weight of 1 meter of the corner 75x75x5 mm is a theoretical value, for the determination of which there are several ways. The simplest of them is tabular. In addition, the rapid finding of the desired value is made using an online calculator. The weight of 1 m corner with such sizes is 5.8 kg. If necessary, you can perform an independent calculation of this indicator. The theoretical mass is calculated using a special formula.

Useful information! For equilateral products, equations are used that are not suitable for determining 1 m of the mass of non-equilateral parts.

With the help of the above methods, you can find out the mass of products of the same width, but having different thickness indicators, for example, steel corners 75x75x6. The weight of 1 meter of these parts is 6.89 kg.

Steel corners are an indispensable building material, which is used for the installation of frame structures. Parts that have a small mass are actively used in the furniture industry and are also used for commercial purposes. Calculation of the mass of steel products is a necessary measure, which allows to determine the conditions of transportation and construction nuances. To calculate the weight, you can use a tabular method, an online calculator, or you can perform all the actions yourself using special formulas.