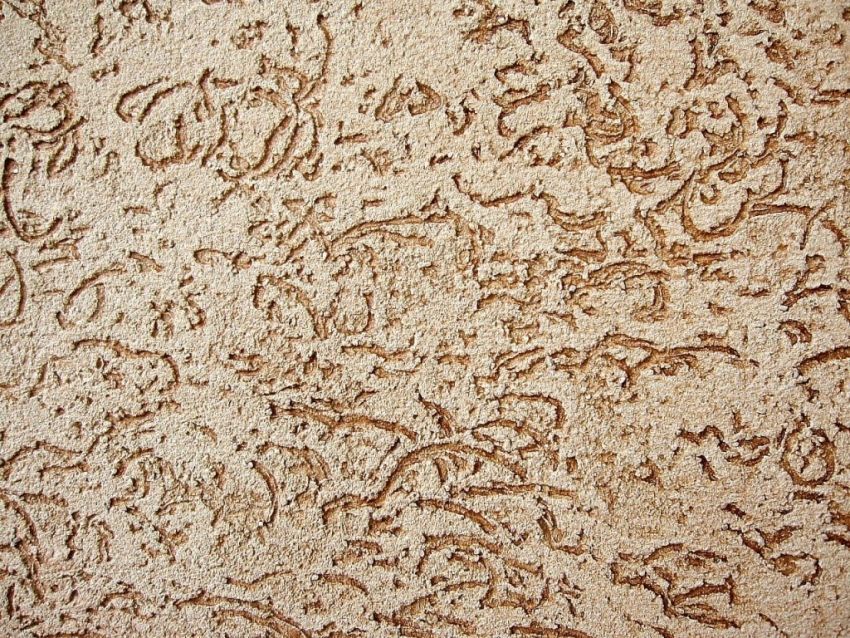

One of the most interesting, original, cheap and easy to apply options for facing the surface is considered textured bark beetle plaster. With this material, which is used for both exterior and interior decoration, you can create a unique, colorful and durable surface. The technology of applying bark beetle plaster is described in detail in this article.

Technology of applying bark beetle plaster: preparation of the base

Bark beetle plaster can be applied on previously prepared brick, plasterboard, chipboard, concrete bases, sandwich panels and on the layer of insulation.

Before performing facing works, the surface should be thoroughly cleaned from old finishes, oil stains, dirt and dust. If the base has significant irregularities and cracks, it should be leveled using plaster, lime or cement mortar for plaster walls. The proportions of the constituent components must be strictly observed in order to obtain a finishing material of good quality with the necessary strength characteristics.

Helpful advice! To seal the seams and large cracks, they must first be embroidered with a grinder, and then sealed with plaster putty.

If wall cladding is performed in a room with a high level of humidity, then the surface must be treated with an antifungal compound that will prevent the formation of fungus and mold.

To create good adhesion of the base and future plaster, the leveled surface should be treated with a primer, using a roller, brush or spray gun. It will also regulate the absorptive capacity of the prepared surface and ensure uniform drying of the decorative plaster layer. In order to prepare the future color shade of the surface in the primer, you can add the coloring pigment of the desired shade. Under the “bark beetle” plaster it is better to use a thick acrylic primer, which is able to prevent excessive absorption of moisture while working with this decorative mixture.

Concrete and cement-lime exterior walls do not need to be treated with a soil mixture. To create good adhesion, it will be sufficient to moisten the surface thoroughly with water one hour before the beginning of the lining works with plaster.

On a dry coat of primer, which takes about 40 minutes to completely dry. at a temperature of 20 degrees., should be applied to the base layer of plaster mixture with a thickness of not more than 2 mm. At the same time it should be sealed and rubbed. It will play the role of basis for future invoice.

Many owners of country and private homes tend to make the room as warm as possible. For this, exterior wall finish is often carried out with the help of insulation, which needs to create high-quality protection from the negative impact of the external environment. To do this, you must use facade plaster, which is applied on top of the insulating material.

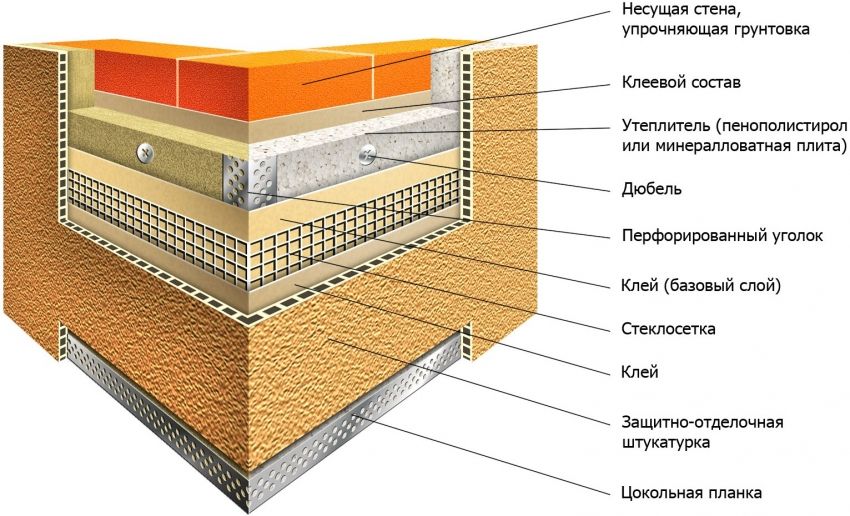

The technology of plastering of external walls involves the creation of a wet facade, which consists of heat insulation, reinforcing mesh and textured plaster.

As a heater for the walls outside the house under the plaster can be used polystyrene foam or mineral wool. The first material is an inexpensive and fairly easy to install product. It is used for thermal insulation of concrete, slag concrete, expanded clay concrete and brick facades.

Mineral wool in the form of double-layer basalt or diabazalt plates is considered to be more durable, non-combustible and “breathing” insulation. This material should be used for walls made of expanded clay, gas silicate, aerated concrete and wooden beams.

The technology of thermal insulation of the facade under the plaster of mineral wool or polystyrene foam involves the use of a special adhesive, which is applied with a thin layer on the base of the insulation. Further, the slabs are bonded to the wall surface according to the brickwork principle.

After the glue composition has completely dried, the insulation boards should be additionally fixed using the dowel-umbrellas. Above the insulation it is necessary to fix the reinforcing mesh of fiberglass with plastic fasteners. After three days, you can begin to perform surface plastering, the principle of which is the same as for the interior decoration of the lighthouses. The cost of plastering the walls outside the building is on average 400-500 rubles / m ?.

Here you can immediately use the bark beetle front plaster, the video of the application technology of which will show in detail the sequence of actions.

Helpful advice! After finishing the “bark beetle” plaster of the facade of the building, it must be protected for two days from direct exposure to UV rays and precipitation.

Features plaster walls on the beacons. Price per m2

Before starting the finishing of the surface, prepare the foundation. The main event is the alignment of the walls. One of the most popular and effective ways is to do plaster walls on beacons. The video clearly shows the sequence of actions.

Before starting work it is necessary to prepare special materials and tools. The first step is to buy beacons for plaster walls, which will act as limiters. They are metal or plastic profiles with holes. The depth of the product is 6 or 10 mm, which is selected depending on the deviation of the wall, the length is 3 m. The shape distinguishes T and L figurative products. The price of a beacon for plaster walls with a thickness of 6 mm is 18 rubles, and a depth of 10 mm is 23 rubles.

If the walls are smooth enough or have minor irregularities, you can perform the plastering of walls without beacons.

Also, you need a mortar for plaster walls. You can buy ready-made material, and you can make your own solution for plaster walls. The proportions of all ingredients must be strictly followed. For the preparation of cement plaster the ratio of cement and sand is 1: 2-3. For the lime mixture it is necessary to take lime and sand in the ratio of 1: 2-4. Clay composition is obtained by mixing 1: 3-5 clay and sand. And to obtain a plaster solution for plaster walls, the proportions of lime, gypsum and sand are 1: 1: 2.

As additional tools you will need:

- putty knife;

- plummet;

- self-tapping screws;

- dowels;

- the rule;

- roulette;

- scissors for metal;

- level;

- perforator for the preparation of the solution.

Depending on the selected mixture and the proportions of the mortar for plaster walls with your own hands, you may need additional tools from various materials: wood, plastic or metal brushes.

Plaster for the walls are selected depending on the type of base. For concrete surfaces, it is better to give preference to cement mortars or lime mixtures with the addition of cement, the amount of which affects the service life of the plaster. For brick walls fit any plaster. However, for better adhesion of the concrete or brick base and the working solution should be installed reinforcing mesh for plaster walls. It must be installed when it is necessary to put a layer of plaster more than 5 cm.

Finishing of wooden surfaces can be done with a gypsum-lime mixture, or with a solution with the addition of clay as a plasticizer. However, one should not exceed the permissible rate of this component, which may contribute to further cracking on the wall surface. Plastering of a wooden surface is necessarily carried out with the use of a reinforcing mesh for plastering of walls, the price of which depends on the material of the product and averages 150 rubles / m ?.

For finishing of gypsum blocks you can use gypsum or limestone gypsum plaster. Cement mortars are not compatible with the plaster surface. It does not require additional installation of the grid.

The most problematic are foundations of foam and gas blocks, which have very low adhesion. Therefore, in order to ensure long-term and reliable adhesion of the base and plaster, it is necessary to fill the grid under the plaster of the walls and use solutions with special additives.

Many experts prefer the gypsum mixture, which has the best performance. It does not shrink, thus preventing the formation of cracks. Also, this material creates additional heat and sound insulation. All the details of working with this composition are described in detail in the video “How to plaster walls with gypsum plaster”.

Important! Gypsum plaster can not be used for concrete foundations, the components of which, reacting with gypsum, repel it. Such plaster will disappear very quickly.

First, you should check the walls and with the help of a level that is applied horizontally and vertically, and identify all the cavities and protrusions. Before you install the beacons for plaster walls, you should mark the surface with a marker. It should start from the corner, departing about 30 cm on each side, marking the places for the extreme beacons. Draw a vertical line. The distance between adjacent beacons should be 160 cm. This is less than the length of the rule.

Helpful advice! Do not divide the wall surface into unequal parts. If it remains about 2 m, it is better to arrange the lighthouses at a distance of 1 m from each other.

To create a horizontal mark, it is necessary to retreat 15 cm from the floor level and draw a line perpendicular to the vertical marking. At the points of intersection of the lines, make holes and drive dowels. Next, you need to stretch the cord through them. Measure 235 cm from the received line (with a ceiling height of 2.65 cm) and create holes at the intersection with vertical lines and hammer in the dowels.

Strict adherence to the sequence of actions when performing surface cladding with textured bark beetle plaster will provide a high-quality, durable, attractive and aesthetic coating that will please the eye for many years without losing its original appearance.