From this article, you can find out what properties and technical characteristics Hammer Paint has on metal: the distinctive features of the material, the scope of application, advantages and disadvantages, the list of components and their functional purpose. The text discusses in detail the existing types of coatings, their parameters and pricing, as well as step-by-step technology for painting surfaces.

Hammer Paint on Metal: Basic Composition Information

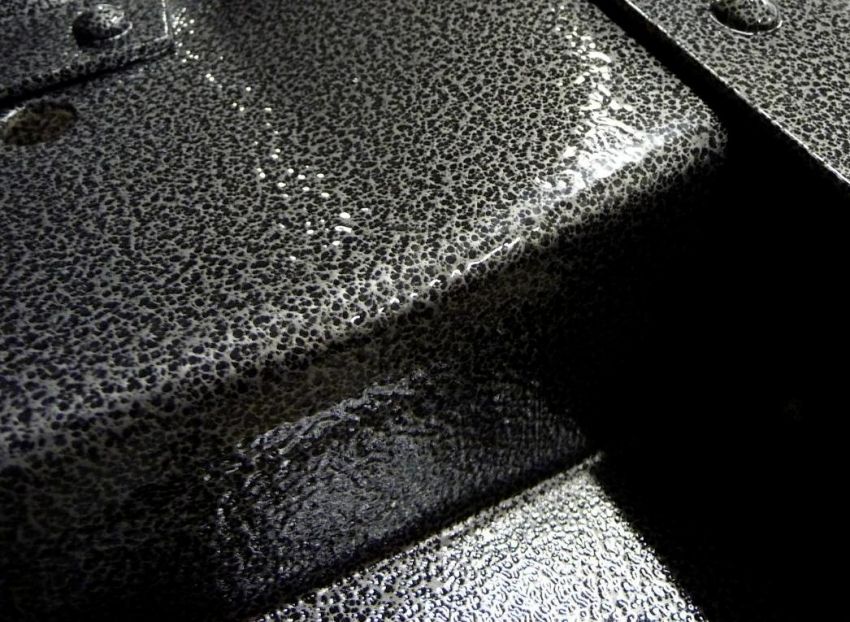

Hammer paint got its name due to the decorative effect inherent in this type of coating. The surface treated with the composition looks like metal embossing, made by hand using a blacksmith’s hammer. This type of finishing material was developed specifically for processing equipment used in laboratories and in manufacturing plants. For this reason, it was not necessary to pay attention to the decorative characteristics; the color range of dyes was previously represented solely by a gray tint.

Due to its high resistance to corrosion and negative external factors, hammer paint has become popular and in demand, and its color palette has been significantly expanded.

To understand the properties of the coating, it is necessary to understand what hammer paint on metal is and what components it includes. The composition has exceptional strength. The dye is made using alkyd-styrene, acrylic and epoxy components. In addition, the composition contains fillers in the form of fine glass and aluminum powder, as well as silicone oil. In the liquid state, the finished dye has a high adhesion. It quickly sets on the surface, and after drying it forms a very high-quality and durable coating.

Note! The high density of the mixture is ensured by the presence of metal powder in the composition. Due to this, the coating is durable, however, applying hammer paint using a spray gun becomes problematic.

When hammer dyes were used not only for protective purposes, but also for decorative purposes, manufacturers added colored pigments to the mixture. The combination of fine glass, aluminum powder, silicones and aluminum flakes improves water resistance and improves the texture of the coating.

The unique composition of the finishing material provided him demand in the market. Good paint for metal with a hammer effect has many advantages:

- high resistance to temperature extremes, which allows the coating to withstand high temperatures (up to 80 ° C);

- there is no need for preliminary preparation of the rusty surface; priming and cleaning can be abandoned;

- accelerated and simple staining system;

- lack of stickiness;

- fast drying period (the dye after aerosol application dries out after 2 hours);

- resistance to the negative effects of environmental factors;

- resistance to vibration, allowing the use of dye for processing the walls of equipment, metal fences, garage doors;

- long-term corrosion protection of metal – up to 8 years;

- safety for human health;

- after full drying, the coating does not emit toxic substances into the air;

- the possibility of using different tools for the application, for example, brush, roller, aerosol;

- no unpleasant smell;

- the possibility of using dye for interior decorating;

- extensive selection of colors;

- maintaining an attractive appearance for 3 years;

- the coating perfectly repels dirt, so that the hammer paint can be used to finish the garage door.

Helpful advice! If you use the aerosol method of application, you can control the consumption of the dye.

Unique properties and improved characteristics ensured the hammer enamel popularity and wide scope of use.

This type of dye is used to process various objects:

- industrial equipment;

- corps of machine tools;

- drain elements, flagpoles;

- garden tools, accessories, weathervanes;

- specialized devices;

- electric shields;

- building structures made of metal;

- metal cabinets, safe structures;

- shelving and office furniture;

- agricultural equipment and machinery;

- fences and gates.

Hammer dye is also used as a decorative coating to decorate products made from tiles, durable plastic, glass. Most often, the composition is applied to gazebos, fences and gates that need anti-corrosion protection. Most attractive of all, hammer paint looks on forged metal products. The coating gives them the original texture and enhances shine.

Scope of application is not limited to landscape design, as the dye is suitable for interior surfaces. After applying the composition on the surface of products made of non-ferrous or galvanized metals, steel, a reliable corrosion barrier is formed.

Best of all, the dye with a hammer effect lays down on horizontal surfaces. When applied to vertical planes, the composition will drain. In addition, it will not be possible to achieve the characteristic shagreen effect. Therefore, it is preferable to consider the possibility that at the time of dyeing the object to be processed will need to be installed horizontally. If this is not possible, it is advisable to buy a quick-drying composition that does not have time to spread too quickly across the surface.

The color palette of the dye includes the following shades:

- brown;

- Navy blue;

- red;

- blue;

- lime;

- golden;

- copper;

- Gray;

- silvery gray;

- the black;

- dark green.

The price of hammer paint for metal depends on the manufacturer, drying time and other characteristics.

Helpful advice! If it is planned to paint a new metal, it is necessary to remove a layer of factory grease, which opened the material surface.

One of the most popular colors is ML-165. It is an enamel made on the basis of alkyd-styrene components. The composition of this brand has a high level of resistance to temperature and excellent adhesive properties. The surface is able to withstand heat up to 130 ° C. To remove this type of coating, it is recommended to purchase xylene, which perfectly dissolves ML-165. For the composition there are no restrictions on the surface for application.

EP-1323ME can be used as a paint-primer for metal. This epoxy enamel has properties and dye, and priming composition. This type of coating is optimal for processing the following objects:

- case part of loaders and automobile cranes;

- elements of cars;

- structures of gates, fences and doors.

It is allowed to use EP-1323ME over rust. Suitable solvents are 667 and 648.

Hammer nitroenamel NTs-221 is a budget dye option. This type of coating is unable to fully perform a protective function, it has a decorative purpose. Therefore, it is not allowed to apply the composition over rust, and its indicator of resistance to temperature effects is not higher than that of a conventional dye. NTs-221 is successfully used for both exterior and interior work.

Not less popular are Hammerite compounds belonging to the expensive segment of coatings. This English-made dye is very popular in the market and can be applied over rust.

Average prices of hammer inks:

| Name | price, rub. |

| NTs-221 | from 92 |

| EP-1323ME | from 183 |

| ML-165 | from 217 |

| Hammerite | from 466 |

Hammer dyes have a different type of packaging, including in the form of cans. Compounds from the BOSNY trademark differ in simplicity of operation, as well as any finishing material in the form of spray. Due to this method of application, it is possible to dose the dye and reduce its consumption. This type of coating is completely safe, it is characterized by long shelf life and fast drying. It is allowed to apply the composition over a surface covered with a small amount of rust.

Note! The dye BOSNY does not contain mercury and no harmful metals (lead).

Hammerite effect dyes create a beautiful decorative coating. In this case, the surface is obtained with a pronounced shagreen which is characterized by a muffled gloss. Hammer effect with a uniform application is manifested throughout the treated area. This type of dye belongs to the category of finishing materials 3 in 1. Also, the composition contains anti-corrosion components. Hammerite effect paint can be applied to rusty objects, and in the presence of loose thick-layer corrosion, preliminary cleaning of the surface for painting will be required.

Italian dye Idea Spray Maimeri is equipped with a high-quality sprayer, so it can even be used to process thin decorative parts on metal products. This type of product has a high rate of concealment, dries quickly and lays well on the base.

Average prices of paints in cans for metal:

| Name | price, rub. |

| Hammerite effect | from 160 |

| BOSNY | from 345 |

| Maimeri Idea Spray | from 662 |

If you use a brush with synthetic pile, this material will melt, because in the composition of hammer dyes there are organic solvents. Regardless of the chosen paint and method of application, the treated surface must be clean. Only in this case the hammer cover will reliably and evenly lie on the base and will last a long time.