To organize a healthy indoor microclimate, ventilation systems are used, which are among the most hygienically correct ventilation solutions. Supply and exhaust ventilation is essentially designed not only to ensure the flow of fresh air, but at the same time the conclusion of the exhaust air masses from the room. In addition, such systems can recycle the heat or cold of the used air.

Advantages of air handling units

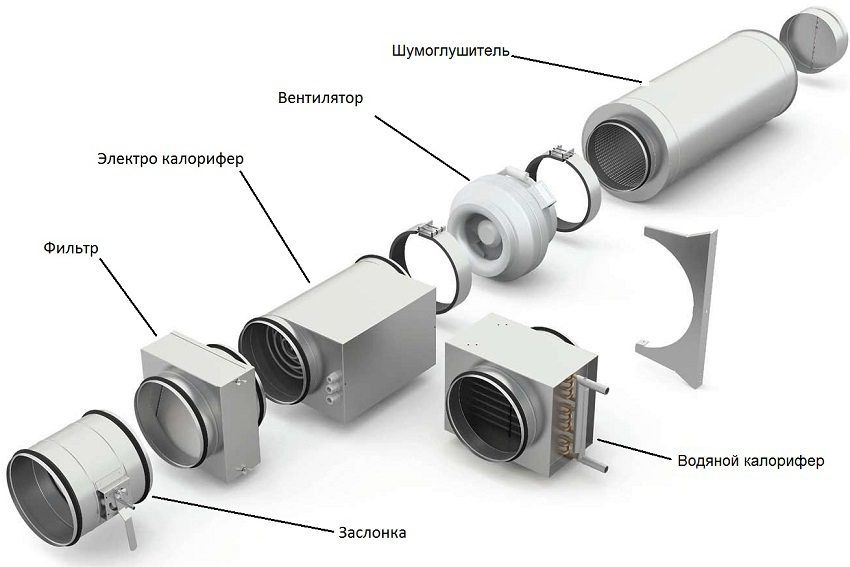

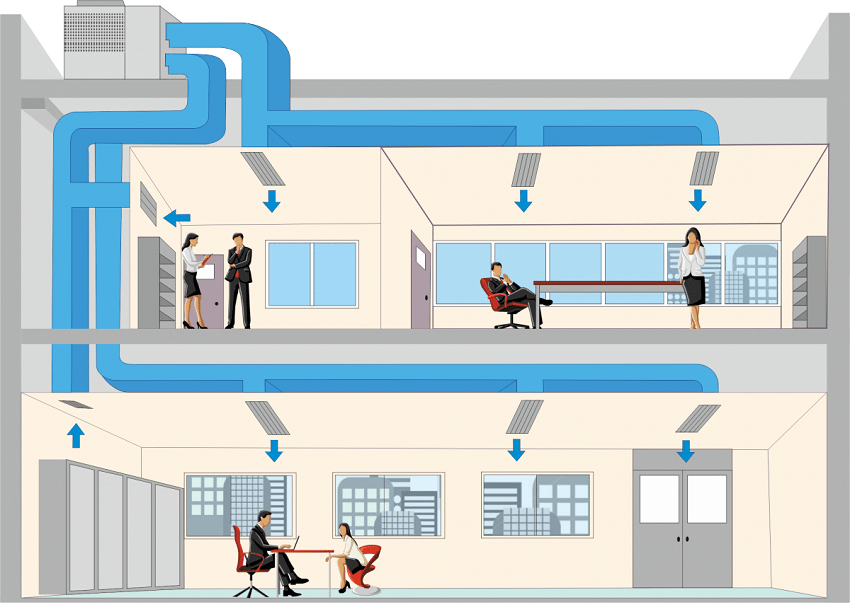

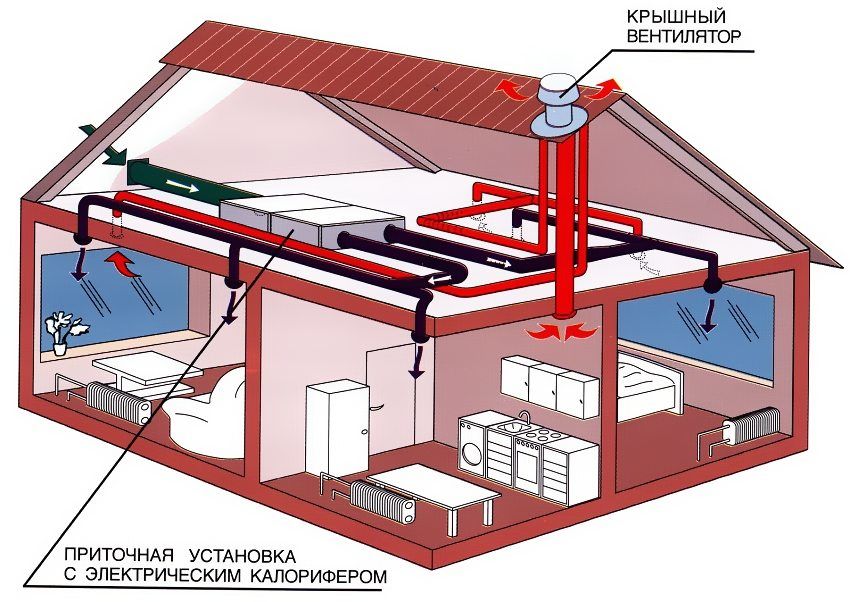

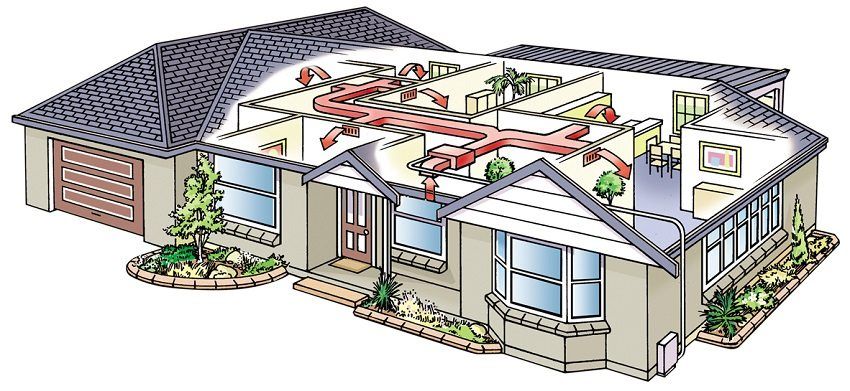

Ventilation and exhaust ventilation systems refer to ventilation with a balanced exchange of inlet and exhaust air. Supply and exhaust ventilation is used in homes, apartments, offices and industrial premises. Therefore, the design of such systems is carried out under the immediate needs of certain premises. The system may consist of separate supply and exhaust units with a common supply and exhaust chamber or from elements assembled in a single compact unit of supply and exhaust ventilation (monoblock), where air is supplied and removed.

The main advantages of such installations include:

- modular system that allows to take into account the necessary power elements in the project;

- absolute harmlessness of materials;

- purification by filtering the supply air, heating, cooling it, and sometimes humidification;

- long service life (in case of proper design and correct installation);

- economy (use of heat recovery).

For ventilation systems of large industries or large offices, as well as the premises of shops, cafes, impressive private cottages, you should make a competent project. The need for a project of supply and exhaust ventilation is caused by the need to minimize costs in the operation of installations.

Depending on the requirements for different rooms, supply and exhaust ventilation is classified according to the configuration and functional features.

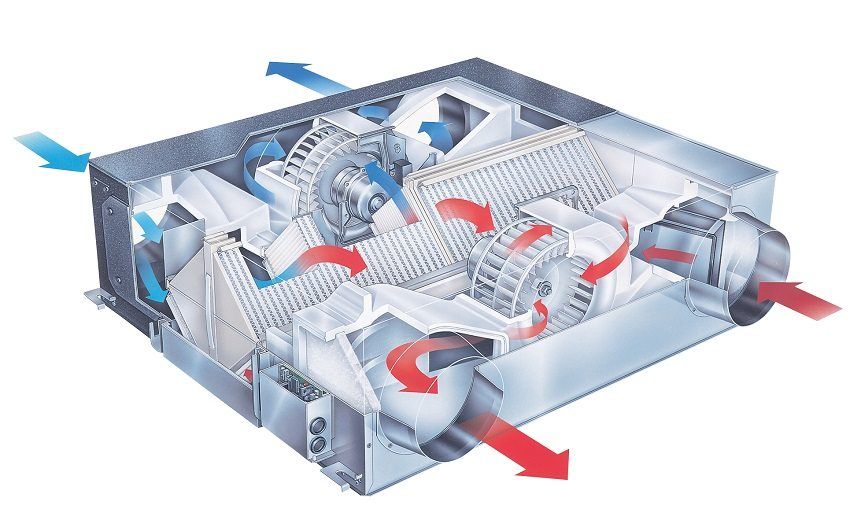

The main function of exhaust ventilation with heat recovery is to provide fresh and at the same time warm air in the cold season, and cooled in a hot period.

Forced ventilation. Functional features of air handling units. Device and types of systems. Management of forced ventilation. Water recovery system. Air heating.

This system is designed so that in winter, the flow of warm exhaust air is not just brought outside, but passes through the heat exchange unit and transfers its heat to the incoming cold air. As a result, the room is saturated with fresh, but already warm air. In summer, the reverse occurs, in which the incoming air is already cooled. Moreover, the installation scheme is such that both flows (inbound and outbound) do not mix with each other.

The process of heat recovery is provided by a special device – a recuperator. There are two types of recuperator: rotary and plate. Lamellar heat recuperator is included in the ventilation project in regions where winters are not so severe. Such a device is economical in cost and copes well with heat recovery at sub-zero temperatures up to 15 degrees. For ventilation systems used in areas with colder winters, use rotary devices. They are more expensive, but effective, and pay off by saving on heating space.

Supply and exhaust ventilation systems with heat recovery are widely used at various facilities: houses, country cottages, offices, hotel and restaurant chains, sports complexes, industrial buildings.

Forced-air and exhaust ventilation with air conditioning combines the ventilation system and air conditioning in one heat-insulated unit with built-in automation. This ventilation system provides a direct flow of heated or cooled air. It has several modes of power ventilation and air conditioning, which are installed automatically. This is due to the regulators, which check the state of the microclimate in the room and, depending on this, one or another mode is assigned.

Installations of exhaust ventilation with air-conditioning are distinguished by high productivity and have a number of significant advantages:

- no need for external pipeline networks and remote units;

- insignificant noise level;

- small dimensions and weight;

- easy to manage.

Automation allows you to make the setting so that the user does not need to change the adjustment throughout the operation of the device, regardless of the season.

Forced-air and exhaust installations can be used for effective cooling of air during the summer hot period. Such plants are additionally equipped with various types of equipment for cooling:

- water cooling unit;

- condensing unit;

- unit combination of refrigeration machine and heat pump (chiller fan coil system).

One of the most widely used methods of ventilation in cooling is the connection to cold water supply, due to which the supply air flow is cooled to the desired temperature. Such systems are the most rational for large objects or premises where storage of products is provided, and is not used in homes and offices.

General trade ventilation is used in the case when moisture, heat, gases, vapors, and odors generated in the room are distributed throughout the room. The project calculates the amount of removed (exhaust) air, which would provide sanitary and hygienic indicators of air inhaled by man.

Traditionally, the volume of extracted air is equal to the volume of inlet air. However, in hazardous industries, a larger volume is drawn to block the spread of contaminated hazardous flow throughout the room. Then the missing amount of air is compensated for by inflow (swapping) from nearby, cleaner, premises or by opening windows and doors.

If there is a lack of heat in the room, general exchange ventilation is arranged using a mechanical method and heating the entire supply air flow. In addition, the outside air is cleaned.

One of the simplest methods of general ventilation is the use of a fan for supply and exhaust ventilation. It is installed in a window opening or wall opening. This installation allows you to extract air from the nearest contaminated area for the implementation of general air exchange.

Helpful advice! With the help of a fan of the air handling unit, it is possible to significantly increase the rate of removal of air contaminated with harmful substances..

If during the production in the shop there are emitted harmful heavy gases, the project proposes to make exhaust ducts on the floor or in the underground channels. In such rooms, where there is no possibility to localize harmful emissions, use of general exchange exhaust ventilation systems.

The parameters of the exhaust ventilation are calculated taking into account the internal volume of the entire room. Having calculated the volume of all rooms, the indicators summarize. According to the standards for two to three hours the air in the room should be fully updated. In the passport data of the fans we find out their performance. And already from it we subtract 50 m? (lost when filtering and moving through the duct).

Next, a ventilation design is made. The project should take into account the range of rooms where the flow process will be slowed down (up to 18%) than in the room where the input is located.

Supply and exhaust ventilation in the office or in your own home can be assembled and installed independently. For a project, it is important to correctly calculate all installation parameters.

For example, if the volume of the entire room is 1000 m ?, then the regulatory air flow is approximately 500 m? / Hour. To achieve this figure, you can apply the appropriate diameter of the duct pipes in conjunction with the power of the fans.

The scheme of supply and exhaust ventilation should be made so that the air intake grille and the fan are mounted on the north side. After the fan filter is installed. Assembling the system, from the main air duct, bends are arranged in each separate room. As a unit of the main duct, you can use a conventional refrigerator where the air will be heated or cooled. In summer, when the unit is turned on, the air will be cooled, and in the cold season, you can use a heater that will give heat to the supply air. You can place an ultraviolet lamp in the refrigerator for additional treatment of outside air.

Helpful advice! It should be emphasized that when using additional elements of ventilation, the flow of air and its speed will change in a smaller direction.

Depending on the needs, supply and exhaust ventilation can be supplemented with various devices. Proper placement of input air intake and exhaust air output remains significant.

Malfunctions in the system of exhaust ventilation usually occur when improper operation, so you should repair and maintain the equipment. System maintenance is basically cleaning or replacing filters.

Maintenance of ventilation is carried out by replacing or simple repair of blocks and individual parts. Depending on the malfunction of the joints, they can be repaired using a soldering iron for pipes or a sealant.

In the event that serious breakdowns or malfunctions are found in the system, it is recommended to overhaul. To perform high-quality overhaul professionals are involved.

Helpful advice! Timely replacement of filters, as well as carrying out the necessary maintenance of supply and exhaust ventilation fans contribute to the smooth and long-term operation of the installation.

With self-assembly, it is necessary to provide for the location of the elements of the duct system, convenient for the production of repair and maintenance of ventilation. After repair, it is necessary to check the tightness of all structures, which is a guarantee of the proper functioning of the ventilation system.

Properly designed and installed air handling unit will help to permanently get rid of the lack of fresh air and divert unnecessary odors to the outside.