Geotextiles have long ceased to be something unusual. Now it is widely used both in construction and in the arrangement of various systems, including sewage systems. Consider the main types and characteristics of this material, how to choose and use geotextiles for drainage (geofabric). What you should pay attention before you buy a geofabric for drainage, and that does not play a significant role.

What types of geotextiles are

Geotextiles are of different types and, depending on the requirements of operation, used in different conditions. Therefore, the main criterion for the classification of geotextile is the material of its manufacture:

- polypropylene or polyester can produce the highest quality geofabric;

- monofilament and staple raw material is obtained product with sufficient strength and quality, suitable for use in most construction works;

- geotextiles made by thermal bonding cannot boast of special strength, since it is the thinnest of all the proposed options. However, it is he who has one of the best performance when it comes to water resistance;

- use for the manufacture of geotextiles blended yarn is not recommended, although such options are also commercially available. The thing is that cotton or wool yarn, which fall into the composition, is very easy to rot. And this is a completely undesirable process when it comes to building or arranging drainage.

It is necessary to decide before choosing and buying geotextiles, where and in what works it will be used. Depending on this, the type of material from which it is made is selected. What is the best geotextile for drainage can be sorted out by familiarizing yourself with its main technical characteristics.

Geo-fabric for drainage or other systems is a material that is characterized by high rates:

- stiffness;

- elasticity;

- porosity.

It is these qualities that make it possible to use it to strengthen the soil, divide the territory, filter wastewater, protect the slopes of the site, drainage facilities, etc.

Geotextile has received particular popularity in Europe, where the construction of highways does not do without its use. The synthetic origin of the material allows it to retain its characteristics for a long time, and its high strength – to withstand severe loads. Some manufacturers make geotextiles whose density is up to 250 kg per tear.

When it comes to private or industrial construction, the geofabric also has its place. It is widely used for arranging urban sewer systems, in the construction of houses, railways, highways, in gardening and for drainage. What is the density of geotextiles required for use in a particular area? For example, for arranging drainage systems use geofabric with a density of 200 g / m? and above, for carrying out landscape works about 100 g / m are enough? , and in the construction of runways for aircraft – 800 g / m ?.

The principle of this material is very simple: it is a layer that is used to separate the other two layers among themselves, while providing additional density. For example, it helps to significantly reduce the risks of dips on the road, and also prevents the area from being washed away by groundwater.

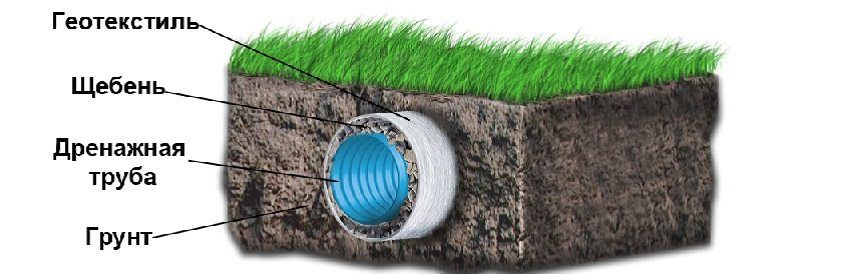

In drainage systems, geofabric plays a very important role – it prevents subsidence of the soil layer in the drainage system, and also prevents the process of diffusion of rubble into the water. Geotextiles play the role of a filter that saves drainage pipe and materials from flooding.

Considering which geotextile to choose for drainage, it is best to give preference to a material made from monofilament. It is easy to identify such material among others – it is given in snow-white color. It is better if the fabric is made by thermal bonding.

If rubble is used as a drainage, small stones are able to pierce the material, creating damage in it. It is worth paying attention to when choosing a geofabric of the required density. The indicator for creating a drainage core will be at least 200 g / m ?.

If it is planned to wrap the drainage system, then geotextiles with minimum density and thickness are suitable for this. At the same time its water-repellent and other technical characteristics should be at the highest level.

There is a huge selection of geotextile materials on sale, and if you do not have adequate experience in this field, you will almost certainly get confused. In order to make the right choice, it is necessary to carefully study all the requirements for drainage geotextiles. Product price also depends on these indicators.

The use of cloth made on the basis of blended materials is not allowed, as over time, cotton fibers tend to leach out, which significantly reduces the ability of geotextiles to filter liquid. Thus, soon the system will require repair, which will entail additional costs. Monofilament – the only option suitable for this case.

It is worth paying attention to the filtration coefficient, which the manufacturer indicates for this type of material. The best indicator is considered to be 125-140 m / day. A larger indicator is required only if the fabric is located in the soil with a high water inflow.

To the density of geotextiles for drainage, there are some requirements associated with the permissible load. So, for the longitudinal load indicator should be 1.9-3 kN / m, and for the transverse – 1.5-2.4 kN / m. At the same time, the total resistance to pushing must be at least 400-500 N.

The remaining parameters, such as the width of the roll, can be any, and are selected depending on the cross section of the filtering layer. The cost of the roll depends on the manufacturer, as well as the density of the material. You should not save on this, because poor-quality geotextiles can later be damaged and require replacement.

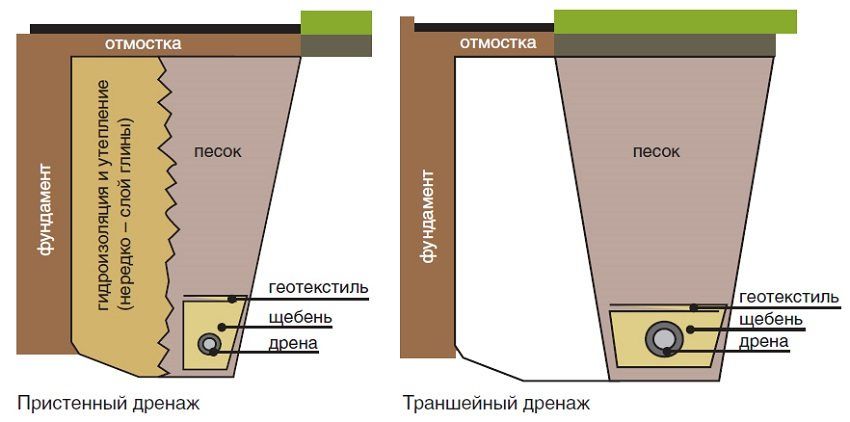

On how well the foundation of the house will be laid, in many respects depends on its durability. That is why you should pay special attention to the arrangement of the drainage system in order to avoid washing the house with underground water. Before starting work, it is necessary to understand exactly how deep the water is, and what type of soil you are dealing with. This will help you navigate when choosing materials: pipes, geotextiles and rubble.

First of all, you will need to dig a trench along the entire perimeter of the foundation. It should be dug out with a slight bias towards the direction of water movement. The width of the recess is calculated on the basis of the diameter of the pipe, as well as the required distance around the tube. For example, if you put a pipe with a diameter of 11 cm, then the reserve of space that is allocated for rubble will be about 10 cm.

Note! In the presence of a blind area, the trench must be placed along it.

Then it is necessary to fill the sand at the bottom of the trench. The thickness of the layer should not exceed 5 cm. Geotextiles are laid on top, which is immediately filled with rubble. The pipes are laid out on top and rubble is filled up again.

The top and side layers of rubble should be at least 10 cm. All these components are covered with geotextile, which is held together with a wire with an interval of about 30 cm. Then everything is filled with soil and the drainage system for the foundation can be considered finished.

Too close location of groundwater can have a very negative impact on the life of plants that grow in the garden. However, the method of combating this phenomenon was thought up long ago, and today it is fairly easy to implement even with our own efforts.

In order to divert water from the site, it is necessary to dig narrow trenches in the form of a fir tree throughout its area. They will be placed narrow pipes with a diameter of 6.3 cm. They are cut into segments of the required length and using special tees are connected in places of turns.

It is at this phase that attention must be paid to the role of geofabric. It is necessary to make a drain pipe in a geotextile filter. Each section of pipe must be wrapped with geofabric at least three times, and the winding must be fixed with the help of wire.

After that, the layers are laid out in the following order: crushed stone, geotextiles, crushed stone, earth.

Helpful advice! At this stage, geotextiles must be overlapped to provide more reliable protection.

One of the variants of geofabric, which today is widely represented on the market, is dornit. So called canvas, made from polymeric raw materials and used in the construction industry for filtration, reinforcement and as a drainage. At first glance, Dornit is not much different from ordinary geotextiles, however, it is not.

The technical characteristics of geotextile dornit are in many ways superior to other similar materials, primarily because of the method used in its production process. Needle-punched heat-treated geotextiles are capable of withstanding loads that are much higher than allowable for ordinary materials.

Non-woven igloprobivna geotextiles are made by a special technology that allows you to improve the quality characteristics of the material. This made it possible to use it in many areas. For example:

- in the construction of railways and highways;

- for laying pipelines;

- as the basis for laying paving slabs;

- for the equipment of flat parking areas.

Finding its place in many areas, Dornit helps to successfully solve the following tasks: increasing the strength of structures, separating soil layers and drainage, filtering and preventing soil leaching processes, protecting drainage systems from contamination.

Despite its excellent technical characteristics, geotextiles have an affordable price. For example, the price of geotextiles for drainage per 1 m? is in the range of 10-20 rubles. Domestic material has a lower price per square meter. Geofabric for drainage import manufacturer will cost a little more.

Note! Regardless of the price, you need to buy a geotextile for drainage that will meet all the requirements for the geotextile for this type of work.

The price of geofabric directly depends on the following indicators: density, strength, method and material of manufacture and manufacturer. Before you buy a geofabric, be sure to familiarize yourself with its technical characteristics.

If you plan to entrust the installation of the drainage system to professionals, then you should familiarize yourself with the rates of laying geotextiles. On average, the price of a geotextile laying job starts from 30 rubles per 1 sq. M. It is easy to calculate that it is almost 2 times cheaper to buy geotextiles for drainage and install it yourself with your own hands.

In order to understand how to use geotextiles in the process of arranging the drainage system, consider what it is needed for and what kinds of it are. Based on the existing topography, one of two drainage options is used:

- open;

- deep.

The first option is dug channels that are located on the surface of the earth. They are easy to mount, but they have a rather unsightly appearance. If we are talking about the arrangement of its own plot, then this option can be called unsuitable.

The deep system is not visible from the outside, as it is laid underground with the help of special pipes and deeply dug trenches. It is to ensure the safety of pipes, as well as for the arrangement of the interior of the tanks, geotextiles are used.

As mentioned earlier, the geofibers are widely used for arranging drainage systems in private areas and in the local area. Depending on the purpose and, accordingly, the density, the price of geotextile for drainage will also vary.

Another important condition that must be met in order for the geofabric to fully fulfill its role is to properly place it in the drainage system. To do this, there are rules, following which you can achieve the desired result:

- the bottom of the trench must be completely clean of debris. Walls should be as smooth as possible;

- it is recommended to unpack the acquired geotextiles immediately prior to installation, as the material is sensitive to the effects of sunlight;

- if necessary, the fabric can be cut to the desired size before laying;

- geofabric must overlap;

- categorically it is impossible to use those pieces of fabric that are damaged;

- Laying should be done in such a way that the web is not too tight. At the same time, the formation of waves and folds is also unacceptable;

- if we are talking about laying geotextiles for drainage on large surfaces, then at this time it is necessary to fix the already laid segments to avoid their displacement;

- in order to preserve the integrity, as well as to minimize the negative effects of ultraviolet radiation, the draining material should be filled in a trench immediately after installation;

- when the entire layer of drainage material is filled and compacted, the lateral edges of the geofabric must be wrapped inward. At the same time free edges should have a length of at least 20 cm, this will help to avoid the likelihood of filler contamination

- when all the edges are wrapped as expected, you can cover the trench with earth.

Another important question that arises in the process of work – which side to put geotextiles? Here even opinions of experts were divided. Some of them argue that there is no significant difference, and the fact that one side is rough and the other smooth is just the cost of production. Reviews claim that no matter which side to lay the material, the characteristics of geotextiles remain unchanged.

Some manufacturers focus consumers on the fact that putting a geofabric should be a smooth side down. In this case, recommendations on which side to place the geotextiles in the drainage will necessarily be contained on the product packaging.

Another opinion on the question of which side to lay geotextiles suggests using a rough surface for better adhesion to the ground.

In any case, when deciding which side to put the geotextile on the ground, it is best to listen to the instructions of the manufacturer of the drainage geotextile that you decided to buy.