Modern technologies have made a significant step forward in terms of housing arrangement, however, the stove for the wood burning did not lose its relevance. Country houses and cottages in matters of heating living rooms far behind apartments. Effectively maintain comfort in rooms of this type helps stove heating, using wood as fuel.

Wood-burning stoves: classification and common features

Antique furnace designs of the classic type were made of brick. With the advent of new technologies, the range of products has expanded significantly. The main advantages of modern wood-burning stoves are mobility and compact dimensions. The material used to make the case has also changed. In most cases, metal or cast iron is used.

Note! In metal constructions, the outer walls are covered with a special dye with heat-resistant properties for protection. In some cases, stone facing is performed.

Advantages of modern models:

- simple operation system;

- compactness;

- quick and easy installation scheme (there is no need for preparatory work);

- universality (several fuel options can be used: firewood, coal, waste from the woodworking industry);

- possibility to carry out work in the mode of long burning;

- high level of efficiency;

- environmental friendliness;

- profitability.

If you do not delve into the features of each manufacturer and the characteristics of individual models, the structure of a standard furnace for giving a metal or cast iron in most cases the same.

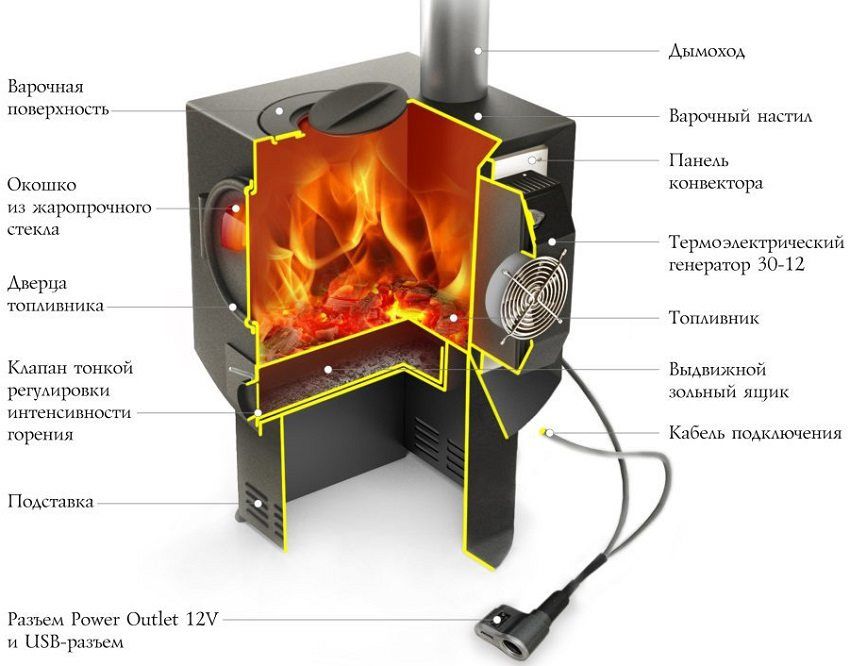

The design includes:

- fuel chamber (firebox) – the area in which the combustion of fuel occurs;

- an ashpit – a small capacity chamber where ash accumulates;

- grate – an element made of cast iron and containing coal;

- Kamenka – a tray with stones (used in furnace constructions installed in baths);

- chimney – an element designed to remove the products of combustion and carbon monoxide.

Only a specialist can orient in the variety of metal and cast-iron stoves to give on firewood. Many of them have additional features, thereby expanding the functionality.

The review of furnaces for the house on firewood of long burning. The principle of operation of furnaces for the house on the wood of long burning. Types of long-burning wood stoves. Installation and operation of furnaces.

Additional items include:

- afterburner circuit (there may be several);

- cooking stove;

- exhaust smoke intended for auxiliary heating;

- module, the main purpose of which is the generation of electric energy (Kryotherm).

Installation of structures is possible not only in country houses, but also in baths, cottages, greenhouses. Even the installation of outdoor furnaces for gardening, intended for both heating and cooking, is being carried out.

The classification of structures is carried out on the basis of various signs. As one of them is considered the material from which the walls are made. There are many variations of metal, brick and cast iron stoves to give on the wood.

Tip! A modern range of products allows you to choose the design of a universal modification. You can buy a furnace that will work on almost any energy carrier. You can use a variety of fuel options, up to sawdust, pellets and even rubber.

The purpose of the furnace is divided into the following types:

- heating – products are used to heat the rooms in the house;

- heating and cooking (from the previous version they are distinguished by the presence of an additional configuration in the form of stoves intended for cooking or heating food);

- oven-drying – have additional equipment (oven, drying compartment, chimney for the summer season, samovar, hot water box);

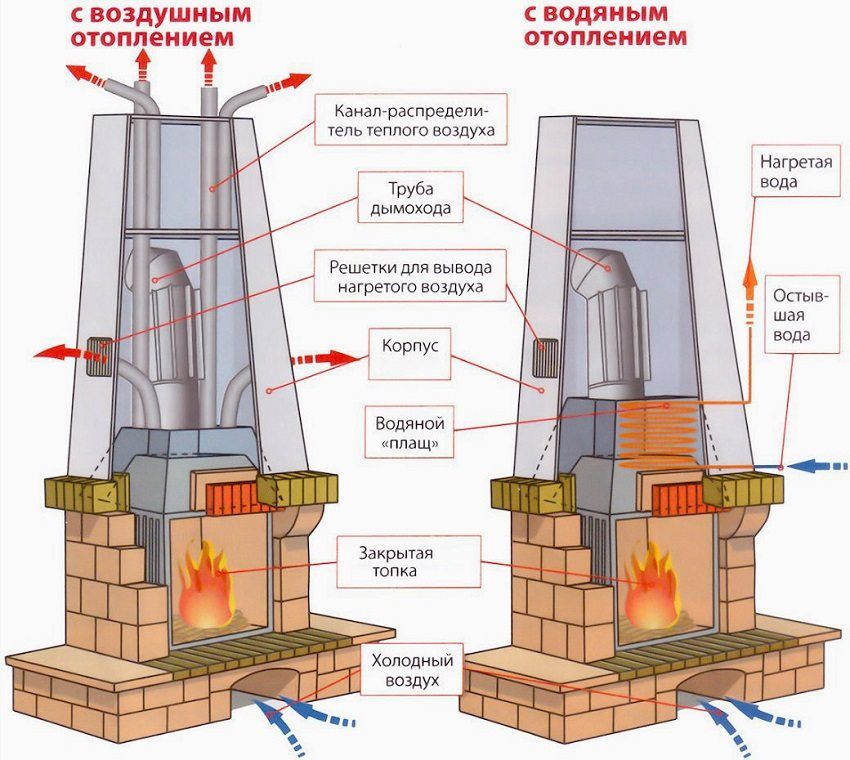

- furnace-boilers – an important element of the heating and water supply in the house, sauna or bath (there is a water circuit).

Complete combustion of wood in a conventional stove takes three hours. Designs of long burning have an adjustable air supply mode. Due to this, a firebox with a single bookmark of firewood can support burning for 12 hours. Thanks to this feature, it is possible to carry out full heating without a constant replenishment of stocks of firewood in the furnace.

A large amount of fuel is put into the furnace. Firewood burning is performed from above. Due to this, the energy carrier does not burn, but undergoes decay. As a result, the period of complete burnout increases significantly. Heating efficiency increases.

The main characteristics that are used when choosing products are efficiency, resource, environmental friendliness, as well as the power of the structure. Models manufactured by different companies may have significant differences in installation issues.

By type of placement furnace designs are:

- classic – set under the wall;

- island – installation is carried out in the central part of the room;

- symmetric – all elements of the furnace are subject to the principle of strict symmetry;

- angular – have an angular type of placement.

The average efficiency is 90%. Operation of long-burning stoves is safe, the appearance of the structures is attractive. They are not subject to deterioration under the influence of temperature differences and corrosion.

Pig-iron furnaces for gardening can not be used as the main type of heating. In country houses, they perform the function of additional heat sources or are considered for an emergency. They solve the problem of lack of access to a gas pipeline or electrical network.

Harmful products that are released in the combustion process, must be displayed outside. For this, a sleeve or chimney is provided. In this case, it has a corrugated structure.

Note! Heating the room with a cast-iron stove takes place very quickly. This is one of the main advantages. Blower helps to preserve heat for a long time.

The dimensions of the cast-iron stoves for cottage wood burning are very compact. Their work is accompanied by a high rate of efficiency. These products have drawbacks. They are few, but they create certain inconveniences. Such disadvantages include high requirements for fuel quality, as well as some features of the sealing of the chimney.

Oven designs, complete with stove, unpretentious in the care. They require much less attention than two separate structures, the purpose of one of which is cooking, and the second – heating the room.

Metal furnaces are made of heat-resistant steel. The properties of this material contribute to the rapid heating of the room. At the same time its thickness is small, so the heat can not be held in the room for a long time.

To achieve a long lasting effect, manufacturers use stainless steel. Based on this, metal products are divided into thin-walled and thick-walled furnaces. The first of them are used as permanent heating structures, the second are installed for the purpose of periodic use as needed.

Stainless steel products have disadvantages. The placement area of the seams in them – the weakest point. It is not recommended to quickly heat such a furnace. This may cause cracks in the housing.

The heyday of the production of stoves for the wood stove to give on the wood fell in the first half of the 20th century. They were the forerunners of modern metal products. The proliferation of gas stoves and central heating systems has gradually supplanted the stoves from the list of public goods. But country and country houses are still dependent on furnaces, whose designs are completely made of metal together with a chimney.

Brick ovens are among the most reliable and expensive product options. The chimney in them has a special serpentine shape, thanks to which the heat in the heated room lasts a long time. The brick oven cannot be compared with the metal construction in matters of rapid heating of the room. This disadvantage is compensated by the ability to retain heat for a long time.

Tip! Brick construction can be used for cooking. Installing a barbecue stove to give in the yard is an excellent choice. The versatility of the product allows it to be used in another capacity: the fireplace will well complement the interior of the room.

Wood stoves made of brick have their own classification, within it are the following structures:

- heating and cooking type – they are equipped with a stove, able to provide effective heating of several rooms and cooking;

- fireplace type – brick and metal serve as materials for their production (in addition to full heating of the rooms, they are able to aesthetically improve the interior);

- Russian type – massive products, complemented by a stove bench (except heating rooms and cooking large structures can be used for other purposes, for example, drying herbs, mushrooms, apples; they are even suitable for taking water procedures).

Proper organization and subsequent operation of the furnace for the brick house with their own hands is able to provide the perfect balance between the heat loss of the room, which is unavoidable, and the heating itself. Therefore, in the room where such a structure is installed, the same temperature regime is almost always maintained.

Basic requirements for stoves:

- The room should be provided with a normal temperature, and the consumption of firewood should not be too high.

- Heating of the stove surface should be carried out evenly, including the lower zone of the housing.

- Thermal returns during the day should be performed evenly.

- The maximum allowable temperature indicator of surface heating is 90-95 degrees Celsius.

- The main criteria for comfort are safety of operation, its simplicity.

- Construction is necessarily made of high quality materials, thereby ensuring strength and durability.

- It is unacceptable that the case had through cracks that contribute to the ingress of flue gases into the room.

Note! External aesthetics is also important. Inaccurate design can ruin the appearance of the room. Therefore, it is better to entrust the construction of the stove construction to professionals or to purchase a finished product from another material.

It can be much cheaper to buy a furnace for the dacha on the wood than to build a structure yourself.

Prices for finished products:

| Manufacturer | Cost, rubles |

| Teplodar (Siberia) | 17000-20000 |

| Teplodar (Rus panorama) | 10,000-15,000 |

| Thermofor | 9000-45000 |

| Ermak | 11000-38000 |

As a result of building a furnace with your own hands, you can achieve optimal parameters and a suitable appearance. Such a design can be perfectly tailored to the size of the room. The same applies to cases when a specialized company is engaged in the construction of the furnace.

Prices for the construction of a brick oven:

| Type of work | Cost, rubles |

| Professional stove installation (with consumables) | 40000-60000 |

| Professional brick laying (1 pc.) | 100-300 |

| Self-laying brick (1 pc.) | 10-150 |

| Consumption of fastening solution (1 m?) | 2000-2900 |

The final cost depends on the price of consumables, their quantity. The high cost of brick structures is obvious, but they provide a lot of advantages. The choice of the furnace depends on the desires of the consumer and his budget possibilities. With finished metal or cast iron products, there is much less trouble. But it is very important to choose the optimal model and quality manufacturer.