Many craftsmen in their practice are faced with the need for new devices, such as a burner for waste oil. Owners of auto repair shops and garages will replace the stove for space heating, especially if there are decent stocks of used oil and other fuels. The burners, if you understand the principle of their work, can be adapted for mixed fuel.

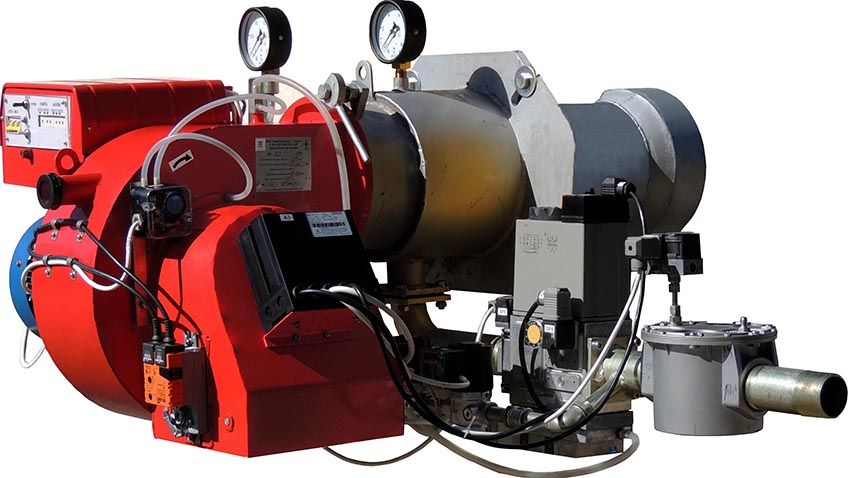

Varieties of burner on waste oil produced in Russia

In the cold season, not only residential but also auxiliary premises need heating. Currently, devices for various types of fuel are used for heating, including testing or used technical oil. In the Russian market you can find devices that process different fuel base, as well as having a narrow specialization. By the type of fuel burned, such devices are:

- gas;

- on liquid fuel;

- combined.

The most simple and economical device for heating the room is considered to burner for testing. According to the functionality of the burner are divided into 3 subspecies:

- welding;

- lighting;

- heating.

The principle of operation of these devices was borrowed from the primitive kerogaz back in the 50s. Quite quickly, the simplest burners became popular, they began to be purchased for heating of country houses and garages. In those days, any fuel was inexpensive, but over time, zealous owners, inventors and innovators began to look for a replacement for gasoline, diesel and kerosene. In the course went fuel oil and waste oil, which is now used as a complete fuel. Today, the device is still relevant, and is also a great way to preserve ecology.

Important! In the room where any device on liquid fuel will be used, whether it be a self-made gasoline burner, a device for testing or a burner on diesel with your own hands, there must be a fire extinguisher!

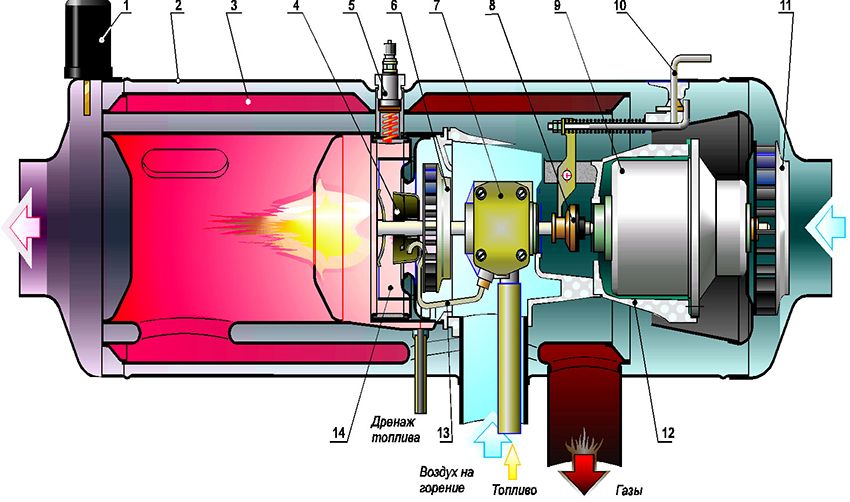

When buying gas burners and similar equipment, people are often interested in this or that element and its purpose in a common design. For example, they want to know from where and where the oil should flow, how it is ignited and so on. When thinking about how to make a burner at home, looking for a model for the construction of a homemade counterpart, the question arises even more. Most often they are interested in replacing injectors and oil tanks with anything suitable from improvised means.

Having at his disposal photos, charts and drawings of the burner for waste oil, not every master will immediately get down to business. The main reason is a large number of specific details.

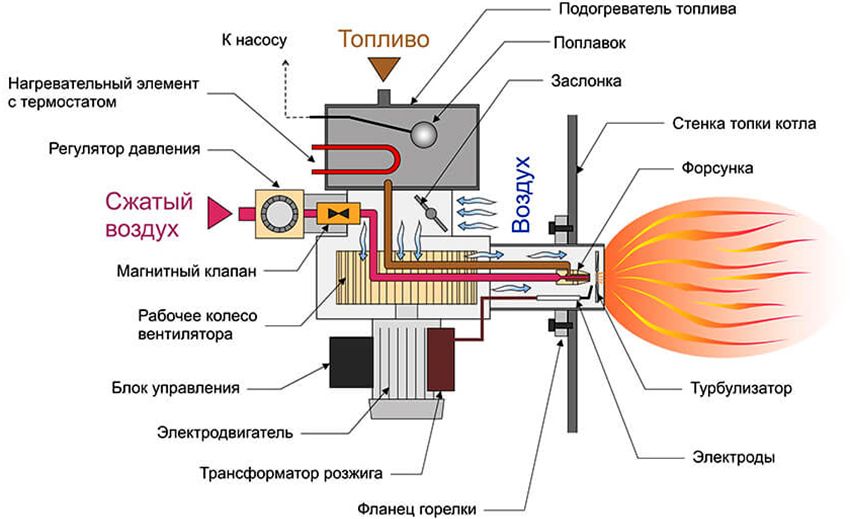

Note! It doesn’t matter what the device was built from – the principle of operation of all the burners is approximately the same: filtered and heated oil is supplied from the main tank and burned in the combustion chamber.

The multicomponent process consists of several stages, and the success of its operation will depend on the quality of the component parts of a drip burner on waste oil:

- sampling and filtration of mining;

- transfer and heating of the purified oil;

- the process of burning to produce heat.

Enterprises that produce finished devices operating on liquid fuel or mining, are equipped with additional options that cleanse the oil. These are the so-called intake floats, which pick up the purest portion of the substance from the surface for heating. This principle of sampling at the moment is inherent in the overwhelming majority of manufactured products belonging to this category.

Further, through a hose made of a material that is resistant to aggressive media, there is a portion flow of waste oil. The tube is usually submerged approximately up to the middle of the main tank; therefore, the solid suspension remains at the bottom, and a cleaner layer leaves for heating and processing. At this stage, it is possible to filter the fuel quite qualitatively without any additional efforts. Dirty impurities, sand and other insoluble components remain on the bottom.

Important! On the purity of the fuel depends largely on the duration of the burner nozzle on the waste oil with their own hands. Therefore, it is worthwhile to take care of at least coarse cleaning of the oil fraction supplied to the furnace.

As you know, filters are single and reusable. Sifting of coarse particles can be done through several layers or filter elements, like with ready-made heaters from Smart Burner. Traditional equipment of different products is about the same: ready-made devices are rarely produced without a filter or elements replacing it.

A small pump for pumping is a standard structural part responsible for the uninterrupted flow of oil. If you organize the supply for a stationary unit according to the principle of communicating vessels, then in an improvised burner it can be fed to the nozzle by gravity.

An equally important stage in preparing the device for operation is to preheat the used oil before complete combustion for heat release. When warming up, the oil becomes more liquid and plastic, as a result of which the optimum consistency is perfectly burned.

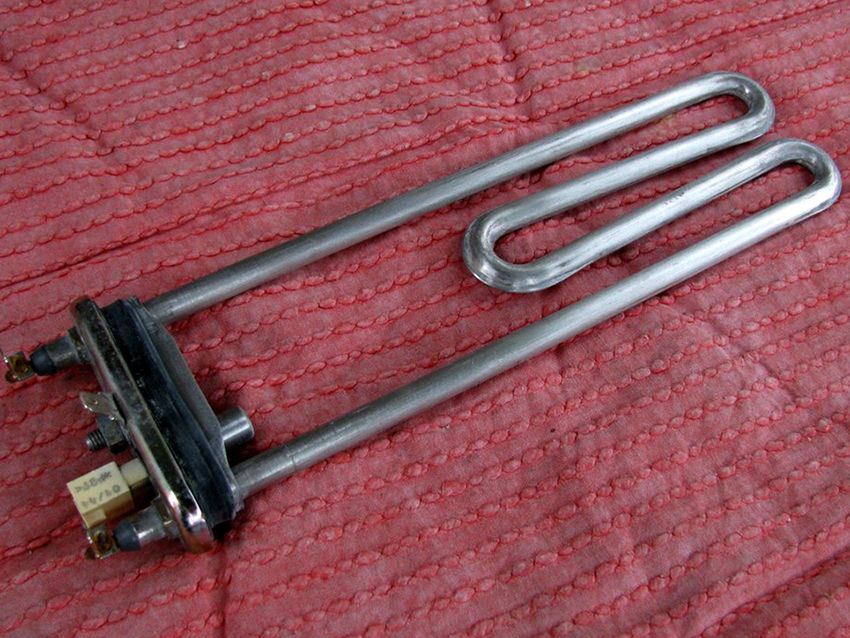

A pre-heating tank or a heating coil is needed for any burner with used oil with its own hands – the drawings show the intermediate location. Usually it is a separate chamber or capsule of a small volume, hidden in the middle of the case. Purpose – as well as possible to warm up the fuel before the combustion process. Finished products most often have a temperature switch that monitors the level of heating. As a rule, they work in the working range of 0-150 ° С.

Attention! Burners adapted for combined suspensions usually have a heating capacity. Diesel fuel in improvised burners on diesel fuel does not need heating.

Manufacturers differently decide how to organize this stage. The burner Dwarf on waste oil (and other similar models) has a small electrical heater inside the tank, which is responsible for heating the miner to the desired level. In the same way as in this case, each manufacturer decides in his own way and the question of the supply of oil. Often, float switches and pumps are responsible for the level of its supply. The system switches itself off when filling the pre-heating tank.

Compressed air is required to prepare the oil mixture for combustion by spraying it. This transportation is directed to the nozzle, which is carried out under pressure. Owing to the supply of oxygen through a separate channel, it provides a combustion process in any device, including a Babington burner with used oil with its own hands. Although the device was originally patented as working on diesel fuel, it was adapted for technical oil.

A successful air supply requires a mini-compressor built into the ready-made liquid fuel appliances. It can be transported in other ways, for example, on the principle of pneumatics. In the absence of compressed air, the nozzle may not work correctly.

Helpful advice! The working pressure helps to keep track of the small manometer, thereby preserving the parameters necessary for the full operation of the entire apparatus.

Air flow control is provided by a special solenoid valve on the body. The expensive equipment also provides air filters for air purification. They will be useful in dusty mini-workshops, boiler rooms or other rooms where the air taken in for the combustion process has many impurities. To operate the burner nozzle with waste oil, you need an adjustable secondary air supply with your own hands. For the synchronous operation of all units are responsible such parts of the burner:

- nozzle (nozzle);

- fuel compartment;

- heating tank;

- air supply valve;

- oil supply regulator;

- pressure gauge to check the pressure (it may not be);

- pressure device (fan).

In the finished devices ignition provide electrodes. The compressed air is supplied through the air channel, from there it enters the nozzle. There after heating comes and waste oil. If the nozzle is clean, it produces a high-quality ignition of the fuel, assuming the appearance of an even continuous flame.

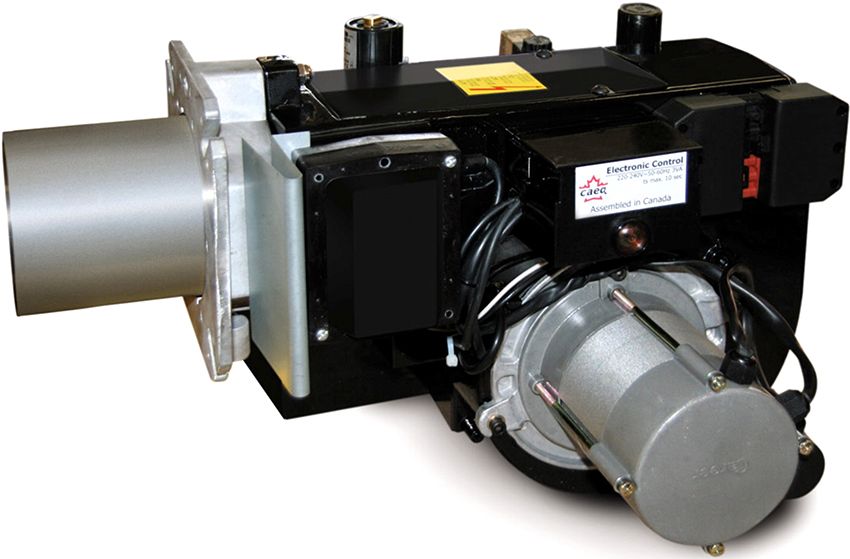

Every invention has its own author, even if his name is undeservedly forgotten by descendants. For example, the British inventor Robert Babington in 1969 received a patent for a stove that runs on diesel fuel, which resembled a lighting kerosene, operating on kerosene fumes. The design of Robert Babington was originally designed for kerosene, then it was adapted for diesel. When the number of cars increased disproportionately, the waste oil had to somehow be disposed of. Therefore, innovators were looking for suitable devices for this purpose.

First, on the basis of R. Babington’s patented invention, a diesel burner appeared with his own hands, then it was adapted for burning oil and other types of fuel. The device, functioning on the mining, appeared much later than the diesel design, but in terms of popularity and safety, it surpassed its predecessor.

After some time, a similar device was offered anew, since the first patent expired, and the oil-fired furnace did not lose its relevance. Similar devices were repeated in different versions, while the Babington burner with their own hands tried to assemble not only self-taught masters, but also design bureaus of reputable enterprises.

The burner on the constructive decision belongs to simple adaptations, therefore with success it is made in house conditions. It is distinguished by a rather high efficiency in terms of obtaining the heat required for heating:

- technological installations;

- small workshops;

- workshops;

- garages;

- warehouse and outbuildings.

Helpful advice! Do not adapt a home-made burner with your own hands for home heating, as the burnt oil has a peculiar smell.

If you look at the photos, drawings and drawings, it becomes obvious that the secondary oil on the curved surface forms a thin film. Through a groove under a slight pressure gas or air is fed into the container. After heating, the oil is sprayed with this air flow, providing high-quality ignition.

It was this method of ignition that became the basis for inventions that became widespread in improvised apparatuses and drip burners on waste oil, produced in the factory. Used oil is, in essence, free fuel that has served a suspension. Therefore, it is considered more profitable against the background of other heat sources:

- solid fuel and briquettes for homemade pellet burner;

- gasoline and diesel fuel;

- electricity;

- natural gas;

- kerosene;

- fuel oil.

Helpful advice! Although working off remains the cheapest basis for heat generation during disposal by incineration, is oil still clogged with impurities recommended to be prepared? achieve water settling and filter out from heavy suspension.

The first apparatuses on kerosene, diesel fuel and oil heavily smoked, emit an unpleasant odor. Later they offered a gasoline burner with their own hands and devices on another fuel raw material, but they were actively searching for low-cost fuel. Oil turned out to be a suitable source of heat, but soot and smell nullified all the advantages. Therefore, all the efforts of the inventors have gone to eliminate these drawbacks burners for boilers for waste oil. This should have been facilitated by the full burning, heating and filtering of polluted fuel.

To get air, in addition to the nozzle you need to drill 2 slots about 8 mm in size. First, a nozzle is attached to the tee, then a copper spiral tube, after which it is attached to the fitting. Part of the oil will drain into the settling tank, which for safety is better to take to the side through the tube. The masters, who possess the secrets of electronics, usually supply the device with a controller and a board for organizing the ignition.

The burner is a versatile design that can be adapted for other types of liquid fuel. Although today such devices are commercially available, their high prices encourage home craftsmen to do something similar with their own hands. In terms of efficiency, home appliances for burning are not inferior to brand-new products designed for heating mini-workshops, greenhouses, and small farms.