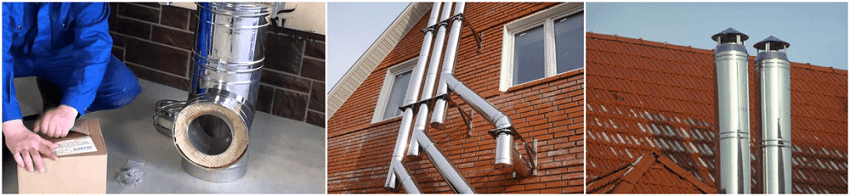

Sandwich pipes for chimneys are a ready-made structural solution suitable for both indoor and outdoor use. Such structures are assembled from prefabricated fittings, regardless of the stage of construction of the house. They are lightweight, have a smooth internal surface and do not require insulation, as they have a fire-resistant insulating layer. Their installation must meet all the requirements for chimneys.

Stainless steel chimney pipes

Stainless steel is an up-to-date material that has found application in various designs, including in the production of chimney channels. The use of stainless pipes for chimneys in almost all types of heating equipment is due to the resistance of the material to the effects of corrosion and corrosive environment resulting from the condensation of water vapor from the exhaust products.

However, not all types of steel can be used for chimney structures. The choice of steel grade suitable for chimneys depends on the temperature of the exhaust products: up to 400 ° C use chrome-nickel steel AISI 304, 321, up to 800 ° C – heat-resistant chromium-nickel-molybdenum steel AISI 316. With regard to galvanized or black steel, they do not have anti-corrosion properties and as chimneys burn out quickly.

The indisputable advantages of stainless steel pipes for the chimney are:

- light weight – contributes to the ease of assembly and does not require the construction of the foundation;

- the modularity of the systems – a huge number of pipes and fittings of different diameters allows you to assemble the structure not only in the house of a new building, but also in the occupied room;

- ease of installation – the quality of the connecting elements ensures a gas-tight assembly of an error-free design. In addition, such chimneys can be deflected from the vertical state to bypass all sorts of obstacles;

- smoothness of the inner surface;

- resistance to burning – contributes to long-term operation of the chimney;

- thin-walled pipe – allows the system to quickly heat up at start-up, reducing the formation of condensate and providing good traction.

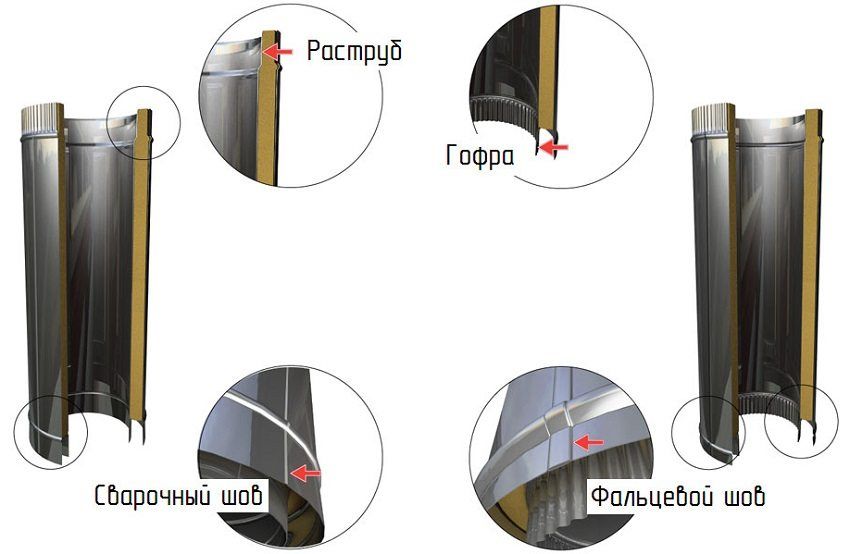

Steel chimneys are produced in two versions:

- single-wall (single-layer, single-circuit) – such flue exhaust systems are designed for use in heated buildings, connecting the boiler to the existing flue exhaust system or for repairing and restoring an old flue by refurbishing;

- double-walled (three-layer, double-circuit, sandwich pipes) – in the construction of sandwich pipes for the chimney there is a heat-insulating layer located between two pipes of different cross-section. Such a device of pipes makes it possible to mount them both inside and outside the building without a thermal insulation device. Insulation is made only in places where chimney passes through the ceiling, wall or ceiling.

The modularity of the design and the wide choice of all component parts makes independent installation of stainless steel chimney as simple as possible. But, despite the ease of installation, such chimneys are part of the overall operation of gas equipment and must comply with the requirements regulated by the SNiP and safety rules of gas facilities.

How to install a chimney? It will be useful to get acquainted with thematic video instructions before you assemble a stainless steel chimney. On the Internet, you can easily find a whole series of video installation of stainless steel chimney with your own hands. The rollers contain a lot of useful information about the nuances of installation and the most frequently committed errors when installing the chimney with your own hands.

Despite the simplicity of the assembly, it is better to entrust the chimney device to a specialist than to do the installation yourself. Stainless steel chimney must meet the following requirements:

- if single-contour steel pipes are used to remove exhaust gases, it would be most appropriate to use the internal installation scheme of the chimney, in which case the system is placed along the main internal walls;

- the diameter of the pipe must be suitable in size to the inlet chimney of the gas boiler, which will ensure reliable tightness of the structure;

- the location of the chimney pipe at the junction with the boiler must be vertical and have a length of 50 cm and more;

- if the finish of the wall, next to which a steel chimney is installed, is made of combustible materials, the distance from the pipe to the wall should be not less than 25 cm, if the installation requires closer placement, it is necessary to upholster the wall with protective screens so that the upholstery on the wall protrudes beyond the dimensions 15 cm tubes on each side;

- It is forbidden to use in the construction of more than three bends;

- the length of the chimney must be at least 5 m;

- the height of the chimney pipe above the roof should exceed 0.5 m;

- The presence of revisions, tees and condensate traps in the design is mandatory.

Helpful advice! When installing the chimney system yourself, remember that an improperly installed structure can cause a gas explosion, a fire and carbon monoxide poisoning.

Answering the question of how to properly make the chimney, it is safe to say that to ensure its safe operation, the design must be completely sealed. It is possible to achieve complete tightness and protection of the structure against moisture by treating the joining points of the system elements with a special sealant for a stainless steel chimney.

It should be noted that special silicate heat-resistant sealants are used for chimneys. Before you install the chimney pipe on the previous link, their joints are treated with such a composition. Sealants are well combined with most materials: stone, metal, concrete, ceramics. Considering that the surface of stainless steel chimney elements is smooth, it is recommended to apply abrasive treatment before using sealant.

Sealant processing works are carried out at a positive temperature from 20 to 40 ° C: this will ensure quick drying of the composition. If you misspell the entire contact surface with a sealant, you get a monolithic structure that will be hard to disassemble without damage. It is worth considering if in the future you need to disassemble some parts of the chimney for maintenance.

Processing sealant produced with a pistol, causing a layer of paste no more than 1 cm thick. It is not necessary to apply the composition with a large layer: they can dry out insufficiently, and if they dry out, they will crack in the future. Some chimney sealants dry for several hours at different temperatures, which will be indicated on the packaging. Available sealants for chimneys only gray and black.

Helpful advice! It is necessary to work with a sealant in protective gloves, since they can cause chemical burns if it comes in contact with the skin.

Thermal insulation of chimney pipes solves several problems at once, the main of which is to prevent the destruction of the roof structure adjacent to the channel and protect the chimney itself from the effects of negative natural factors. Moreover, heat insulation significantly reduces heat loss, which also has a positive effect on the processes occurring inside the system.

Insulating the pipe, it is possible to significantly extend the life of the chimney due to such factors:

- minimizes the ingress of chemically active condensate on the inner surface of the pipe;

- decreases the effect of temperature differences between the outgoing hot substances and the cold air of the atmosphere;

- heat loss contributes to energy saving, which in general makes it possible to use fuel economically;

- increases the mechanical strength of the entire structure, since the insulation casing acts as a frame,

How to insulate a metal chimney pipe? The main requirements for the material of insulation – it is incombustible, and you should also measure the weight of the insulating material with the ability of the roof to withstand it, otherwise it will just push it. The most suitable insulators for the chimney are glass wool or mineral wool. You can purchase a finished cylindrical design with a protective layer of foil. They are of different diameters, so you can choose an option suitable for the construction.

Before independent work can be found with the video, how to insulate chimney pipes with their own hands. A visual description of the installation will help to correctly fix the insulation joints using the most suitable materials.

Helpful advice! It is desirable to provide heat insulation of chimneys at the design stage of the housing construction itself.

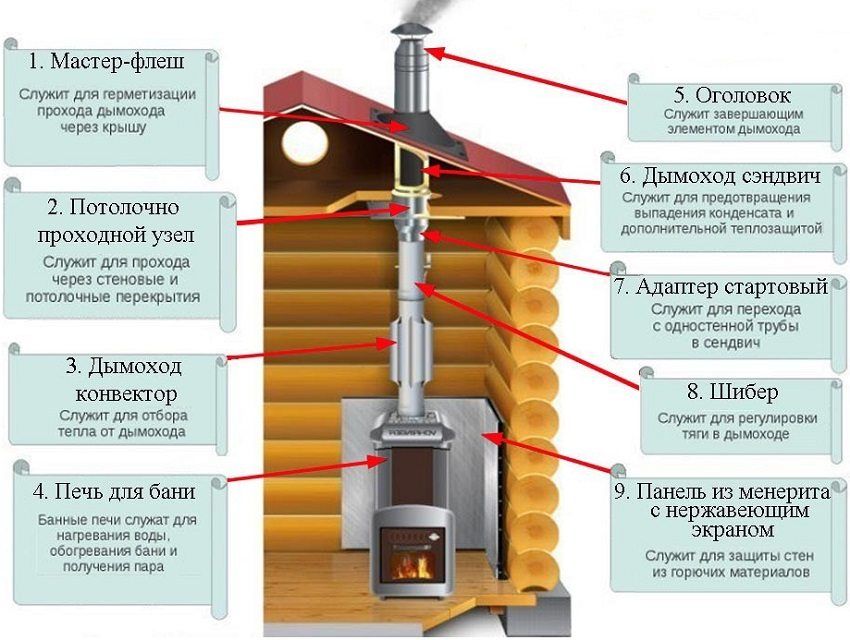

When installing a stainless steel sandwich chimney, you should follow these guidelines:

- when installing a sandwich chimney, it must be remembered that the structure should not have horizontal pipe sections longer than 1 m;

- it is necessary to exclude the contact of the flue duct with the electrical wiring, pipeline, gas appliances;

- the installation of the chimney through the wall is accompanied by the installation of insulated pipes in these places;

- when assembling a sandwich pipe for a chimney with your own hands, it is necessary to provide a revision window for maintenance and cleaning from soot.

How to install a chimney from a sandwich pipe? Before installing the structure, it is necessary to know how to calculate the diameter of the chimney and its total length. The pipe section is selected depending on the type of gas equipment with which it will be used: the more powerful the device, the larger the diameter to choose. The diameter value is indicated in the technical documentation for the device.

Another important size of a sandwich pipe for a chimney is its total length. The length of the structure should not be less than 5 m. If the chimney assumes a slope, its devices use knees from 20 to 90 degrees. The length of the outer part of the pipe must be such that it exceeds the level of the roof ridge by at least 0.5 m, if it is 1.5 m from the ridge. In the case where the chimney is 3 m away from the ridge, the length of the pipe can be flush with him.

Due to the wide range of sandwich pipes of various diameters, as well as shaped parts and components for them, you can assemble chimneys yourself, adhering to the rules and regulations. Be guided by the recommendations of professionals and use for an example a training video on how to install a chimney made from sandwich pipes.