The pellet boiler is a steel or cast iron unit that is used for space heating. As a heating material for such equipment wood pellets (pellets) are used. Such furnaces are an alternative to gas-fired heating appliances. From the article you will learn the main characteristics of pellet boilers: prices, power, etc.

What is a pellet boiler?

In fact, such a device is a solid-fuel stove, which provides room heating by processing pellets. What is pellet? These are cylindrical granules made from wood waste (chips, sawdust, bark). In some cases, this fuel is produced from peat or straw. It is characterized by high environmental performance and does not cause an allergic reaction in humans.

How much is pellet fuel? The price of these granules is determined, depending on the quality and environmental performance. To date, 1 kg of pellets can be purchased at a price of 6.6 to 9.7 rubles. Accordingly, it is easy to make a calculation and determine how much it will cost 1 ton of such raw materials.

The main difference between pellet boilers and conventional solid-fuel devices is the ability to fully automate the workflow. Thus, pellet structures are able to function with minimal human intervention.

Useful information! Pellets can easily deteriorate in a room with a high level of humidity, so they must be stored only in a dry place.

Today pellet units are the main competitors of gas heating equipment. Consider the advantages of using boilers operating on solid pellets:

- high efficiency (up to 97%);

- operation of such furnaces is completely safe due to high environmental performance;

- solid fuel water heaters of other types do not have such a burning duration;

- they are unpretentious in maintenance and have a high level of automation;

- have the ability to equip remote sensors that determine the temperature;

- Pellet unit can be controlled remotely, via a GSM module or a mobile application.

Like any other device, the pellet apparatus has some drawbacks. Consider them:

- the cost per unit of heat released during the processing of pressed wood pellets is rather high;

- for autonomous functioning of the boiler in a remote area located outside the city, it is necessary to purchase a generator and additional technical equipment.

Per month, the cost of pellet raw materials is about 1 ton, which makes it easy to calculate the total cost of heating by such a solid fuel boiler. Internet forums contain a lot of additional information about the features of use, as well as the pros and cons of such equipment.

First of all, today there are two types of pellet boilers, depending on the fuel used:

- proper pellet;

- combined.

Only granulated raw materials are used for the operation of the first units. And the combined models can function both on pellets and on other fuels. For example, a variant of a boiler that processes sawdust is very common.

Another important point – the design of the gas burner. Depending on the type of this element, the following types of furnaces are distinguished:

- flare;

- retory.

Useful information! Retractor burners are used in units that function by processing only pellets, and torch burners are used in combined designs.

It is also worth noting that the supply of fuel to the bunker may be different. Depending on this, the following types of boilers are distinguished:

- automatic;

- partially automatic or semi-automatic;

- mechanical.

The operation of pellet boilers with automatic feeding is regulated by programming the boilers by specialists. In the second case, the oven requires manual adjustment. A mechanical feed involves the manual delivery of pellets in the bunker of the heating unit.

The choice of pellet boilers with a water circuit or other models depends on the specific case. Before purchasing this device, it is recommended to take into account the particular climate in your area. And also it is desirable to go to several specialized forums and read reviews. A pellet boiler can be an excellent option for heating in a non-gasified region, however, its choice should be approached with special care.

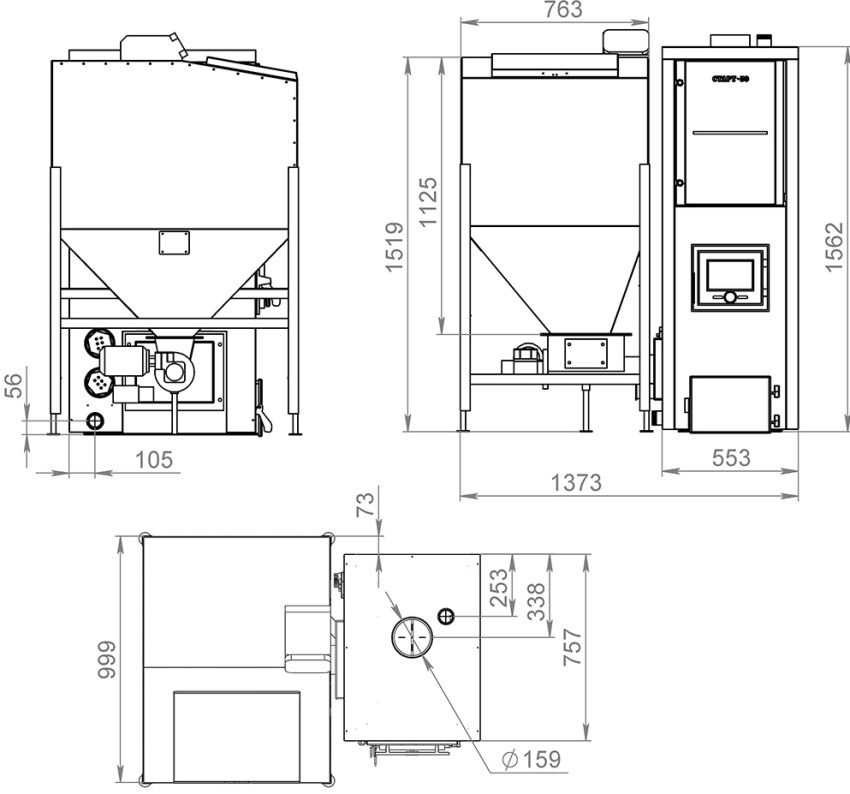

The unit operating on fuel pellets includes three main sections:

- furnace;

- convective;

- ashpot.

Heating department. Presented by the camera in which the combustion of solid fuel pellets. It is equipped with a flare or retractor gas burner and has two doors (viewing and cleaning).

Convective Division. It has a built-in heat exchanger. Depending on the location, there are three types of heat exchangers: vertical, horizontal, and also combined. In this section, the heating medium (water) is heated by hot air, which is released during the processing of fuel pellets. The design of the heat exchanger can be both tubular and plate.

In most cases, pellet boilers are used only for heating purposes and have one circuit. However, in the market there are units with two circuits: heating and water heating.

Ashpot This section of the furnace is necessary for the collection of waste generated during the processing of pellets. After that, they are removed through the cleaning door.

The above structural elements of a pellet solid fuel boiler

represent the main part of it. But for the operation of the furnace, another important component is needed, namely: an APT prefix (automatic fuel supply).

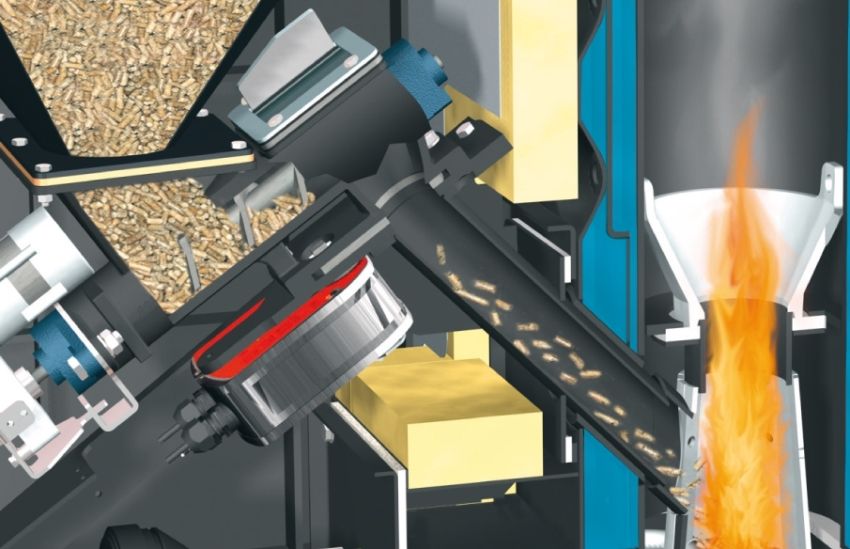

Consider what devices are included in the structure of the PTA:

- bunker;

- screw;

- fan.

A bunker is a metal tank in which fuel is poured for processing. From this tank, the fuel comes in parts to the combustion section. Depending on the location, there are two types of bunkers: internal (built-in) and external. The auger is an important element of the PTA and is required for the supply of pellets. It is driven by a special device – the gearbox.

Note! A fan is needed so that in the absence of natural thrust the fuel does not stop burning.

And also the device of a pellet stove provides for the presence of a control panel. It is necessary in order to set the parameters for the processing of solid fuels and maintain the required temperature.

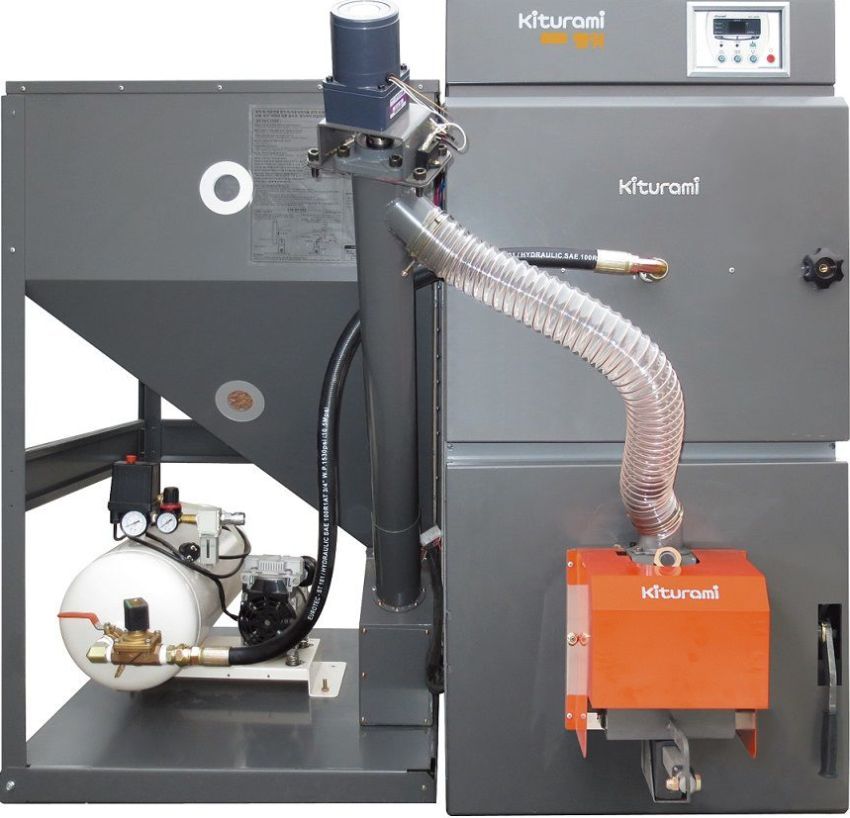

Kiturami manufactures solid-state kiln furnaces in South Korea. Today, the most popular model of this campaign are Kiturami KRP 20-A Premium.

Among the positive qualities of the pellet boilers of the Premium brand, first of all, it is worth noting the high level of efficiency, which reaches 94%. The burner in such devices is electronically controlled. And also they have a modified version of the bunker.

Kiturami Premium 20-A is characterized by high rates of fire resistance and has a special protection against overheating. The management of such a boiler is performed remotely (via remote control).

Consider the main technical features of this unit:

- device power is 24 kW;

- weight – 310 kg;

- the bunker has a capacity of 160 kg;

- the area that such a boiler is able to heat is 300 m ?;

- pellets consumption indicator – 5.5 kg / h.

The KRP 20-A Premium model has a dual circuit design and is used for heating as well as for heating water. The South Korean manufacturer provides a 2 year warranty on its products. The approximate price of a boiler for pellets of this type is 210,000 rubles.

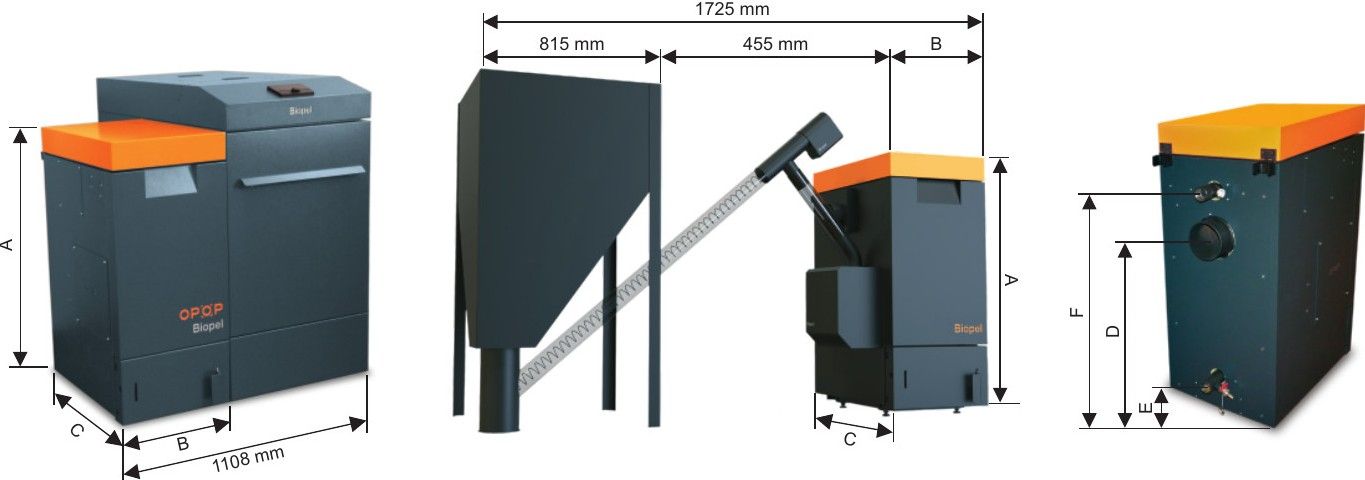

Features pellet stoves OPOP Biopel

Units of this brand are made in the Czech Republic and are of high quality. These boilers are made of steel, which has good heat resistance. Power devices from the company OPOP BIOPEL ranges from 10 to 200 kW (depending on the model of the furnace). This variation allows you to choose a device for domestic use, and for heating small industrial premises.

Products from the company OPOP BIOPEL is equipped with large built-in tanks for pellets. Heat exchangers in such devices are arranged in a vertical plane, which allows to increase the efficiency of the pellet boiler with automatic feed up to 92%.

Useful information! Separately, it should be said that the system of turbulization is established in the OPOP BIOPEL products. It allows you to stabilize the craving and the process of converting solid raw materials into heat.

If necessary, the management of such a furnace can be made via the Internet. Consider the additional functions of the heating equipment OPOP BIOPEL:

- self-cleaning system of heat exchanger or burner;

- ash removal system.

| Brand name | Price in rubles |

| Zota | 180 000–725 000 |

| “Teplodar-Kupper” | 80,000–115,000 |

| “Svetlobor” | 220 000–650 000 |

| “Obshchem” | 150,000–230,000 |

For people who live in areas without a centralized gas supply system, solid fuel pellet boilers are a good alternative. They are able to meet all the household needs of residents of a private house. The high level of automation, high power and performance make such furnaces very popular and in demand among consumers.