A barrel stove is a simple and economical way of arranging heating in any non-residential building, for example, in a garage. For the manufacture of such a stove, stoves used metal containers, the volume of which is 200 liters. To perform a reliable and efficient heater from a barrel, it is necessary to understand the principle of operation of the stove and follow the instructions clearly.

Advantages and disadvantages of a homemade barrel stove

Currently, there are many options for self-manufacturing stove for household needs. To assemble the stoves use old gas cylinders, as well as sheet metal. In the first case it is quite difficult to get the necessary capacity. As for the sheet iron, it is not cheap. However, there is a more affordable source material from which the easiest way to perform a heating unit is a metal barrel per 200 liters.

Why is it recommended to use just such a volume? The reason is quite simple. When assembling a stove with the hands of the stove, it is necessary to take care that it contains a large amount of fuel. This will maximize the time interval between downloads of new lots of firewood. In addition, the dimensions of such a capacity make it easy to allocate a place under the ash pan.

Most often, these self-made structures are used for heating basements, garages, and workshops that do not provide independent heating.

Note! Before using the barrel, you must inspect it for rust. It is strictly impossible to use tanks, on the surface of which traces of corrosion are traced. These vulnerabilities under the influence of high temperatures simply burn through, which can cause an emergency situation.

In order to answer the question of how to make a stove, it is necessary to carefully study the instructions. Using a metal barrel to design a heater has other advantages. For example, the natural dimensions of the tank do not impede the free burning of fire. And also such a stove does not require the selection of special fuel.

As with any other device, home-made stoves are also characterized by some disadvantages. During operation, the vessel body is heated to a very high temperature, since the metal sheet has a small thickness. Thus, during the operation of such a stove, it is strictly forbidden to touch it. You can do the stove out of a 200-liter barrel with your own hands pretty quickly (in just a few hours).

Such stoves have low efficiency, which is explained by the peculiarities of their design. During operation, part of the heat energy simply disappears into the chimney. Experts do not recommend using coal as a fuel for such barrels. It is all about its high temperature of burning which thin walls can not withstand.

Before you start self-assembly of such a device, you need to understand how it functions. Understanding the principle of action allows us to simplify the process of making such an improvised stove.

Sawdust or firewood is used as fuel for a homemade stove from a metal tank. Compressed sawdust is distinguished by the fact that they are processed for quite a long time inside an improvised furnace. Among other things, the cost of such fuel is minimal, so it is widely used.

The diameter of the 200-liter barrel is 600 mm. If desired, you can perform a fairly functional design, which also will have an attractive appearance. Dimensions of a 200-liter tank allow placing a hexagon inside it, the sides of which will be equal to 314 mm. In this case, according to the technology of manufacturing, the devices resemble traditional oven units.

It should be noted that the finished device has not very high efficiency – only 15%. To increase efficiency, another component is often added to the home-made design – the screen. A reflective shield certainly helps to increase efficiency, but this solution also has a negative side. The use of a heat reflecting screen leads to a decrease in the operational life of an improvised stove.

Useful information! The main reason that the furnace has a rather low efficiency is the height of the tank. Barrels with a capacity of 200 liters have a length of 85 cm. The second problem is a very thin sheet of metal, the thickness of which rarely exceeds 2 mm.

It should be noted that if the grate in the unit rises due to the high location of the blower, then the efficiency of the device decreases. This is due to the fact that heat in such a structure is dispersed into the air through its lower part. To solve this problem, it is necessary to hide the lower part of the stove from the barrel in the brickwork. With your own hands, not only instructions, but also educational photos and videos will help to perform such an assembly.

The life of the burrshack, made of metal barrels, averages 3-4 years during normal operation. To raise the efficiency uses a lot of tricks. However, it should be said that with all the desire to get more than 20% return on a homemade unit will not work.

From the choice of the barrel depends on the technical characteristics of the future heater and its effectiveness. In order to assemble yourself a stove-stove, you must prepare a metal tank, the recommended volume of which is 200 liters. Of course, the stove can also be produced from a less overall capacity, however, in this case, the efficiency of the heater decreases, which is already quite low.

You can use any metal barrels made of steel material to assemble the stove. Steel has a good resistance to high temperatures, so its use for the assembly of the heating unit is more than reasonable. For the same purpose, you can use the barrels that were used for storage:

- oils;

- paints;

- fuel;

- bitumen;

- liquid glass;

- sand.

All containers produced and used for the storage of various compositions are divided into types according to several criteria. First of all, they can be with or without a closed top. And also such tanks differ from each other in thickness of the bottom and open cylindrical structural element (shell). Regardless of the variety, for the production of a metal furnace with your own hands, it is necessary to pre-clean the tank.

The operational life of such a stove in any case depends on the thickness of the walls of the barrel. On this basis, it is not recommended to use tanks that have a wall thickness less than 2 mm for assembling a heating unit. The shelf life of the device is also affected by the frequency of its use.

Note! The most appropriate is the use of barrels for the manufacture of which stainless steel is used. This material has the highest technical characteristics, including resistance to high temperatures.

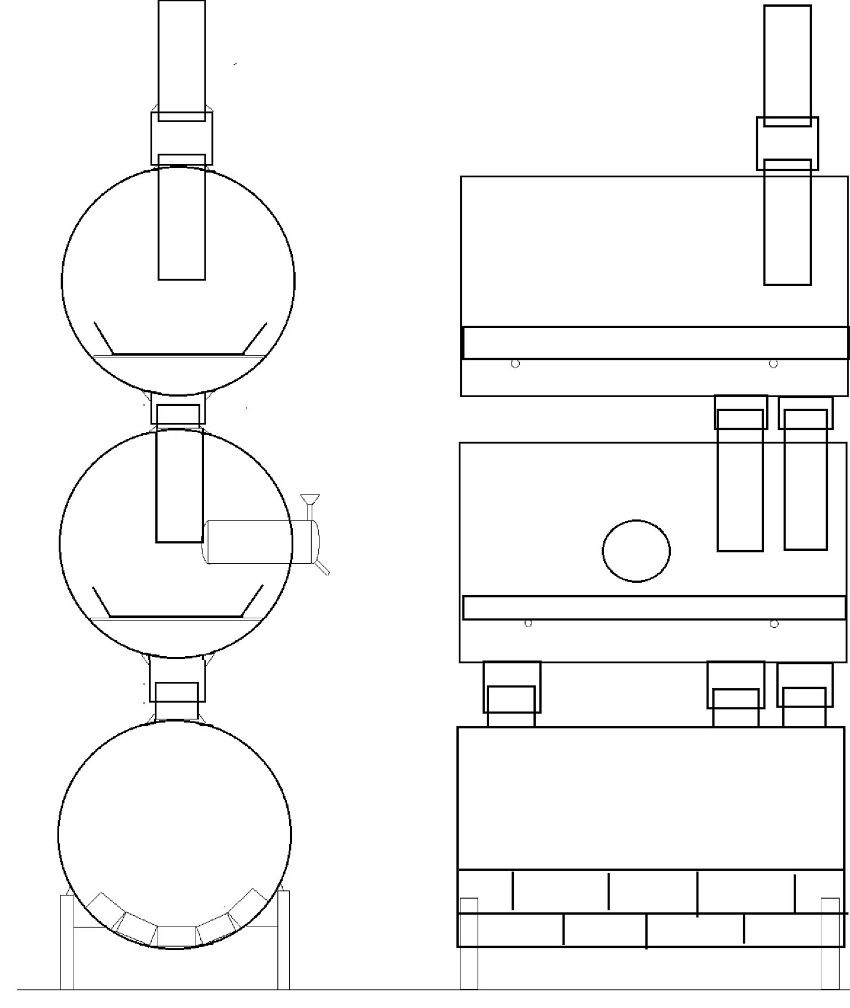

Before proceeding with the assembly of the unit, it is necessary to perform a drawing of a long-burning furnace. The more detailed it is, the less the likelihood of making mistakes during the design of the heater.

Depending on the plane in which the metal reservoir will be located, there are two types of home-made logs: vertical and horizontal. Each of these types of heating devices has its own advantages and disadvantages.

The furnace of a vertical barrel type is not installed on the floor, but on the legs. To complete the door, you need to cut the side of the tank and provide it with loops. It is important to remember that the hinges must be fixed to the barrel and the door not from the inside, but from its outer part.

A mandatory element of this design is a metal plate with perforation, which is called the grate. To fix such a lattice, you can use the usual corners. In order to perform the blower, you will need to prepare a metal pipe with a gate valve. The thickness of the metal walls must be sufficient, otherwise the structure will quickly burn through.

The damper for a long-burning wood-burning stove, located in a vertical plane, is fixed on special bolts. When igniting the fuel inside the tank, it is necessary to open the blower to the limit.

At the top of the canister must be made a hole in the shape of a circle. It will be needed in order to connect a chimney structure to a homemade stove. Docking pipes with a metal surface is made using welding equipment.

The function of the grate is to protect the bottom of the canister from burning, as well as to retain heat energy. Thus, this element is necessary when installing a home-made long-burning furnace.

Before assembly, it is recommended to create an individual drawing of the device. It should be as detailed as possible, contain a drawing of the future unit and its individual components, as well as indicate their dimensions.

Design features are determined depending on the purpose of the device and the place where it will be located. If you wish, you can download the finished drawing of the stove on the Internet. However, in this case it is necessary not to make a mistake with its volume.

The vertical type of homemade heating device is easy to assemble. It is possible to find application to such unit both in the private house, and at the dacha. Firewood used to kindle a heating device of this type is selected depending on the dimensions of the firebox.

From the barrel, which has a volume of 200 liters, it is also possible to make a heating device located in a horizontal plane. In this case, it is also necessary to prepare the support structure. Its height is calculated taking into account individual operational features. When choosing this indicator, first of all you need to focus on the dimensions of the room in which the homemade heater will be installed.

In the drawing of the furnace must take into account the peculiarities of its location. The assembly of such a structure takes place in an almost identical manner, as is the case with a vertical heating device. Let us consider in more detail the process of self-production of the stove from a metal canister.

Note! The ash pan dimensions should not exceed 1/3 of the height of the canister. The size of the barrel 200 liters (more precisely, height), as a rule, is 85 cm.

At the bottom of the tank, you must make a hole that will be used to remove the ash. It should be understood that its parameters should not be too large. Next, you need to make an ashpit. As a material for this element, an ordinary metal sheet of appropriate thickness is used. Then it should be docked to the bottom of the heater. For this it is customary to use welding equipment.

Note! In a room that will be heated with similar equipment, it is necessary to organize a competent ventilation communication. It is best to use a structure that is of a forced type, since natural ventilation in this case may not be enough.

For the manufacture of stoves worth using only high-quality, reliable materials. Before starting work it is recommended to study the video on this topic. Photos of stoves also help to understand the intricacies of the assembly. The unit, which was executed correctly, is able to serve more than one year.

Thus, in order to manufacture the stove from a metal barrel, you do not need to have any special knowledge. Strict compliance with the instructions, as well as an understanding of the principles of operation of this device – that’s all you need to know to make a reliable unit.