Sometimes it is advisable to make a solid fuel boiler with a long burning with your own hands: drawings and diagrams are freely available. The ability to handle the tool and skillful hands have a good service in the construction of your own house or cottage. There is always a need to build any structure yourself. After all, it greatly reduces the cost of any venture. No exception and heating units. In the old days, people hired a stove-setter for laying brick ovens. Today, solid fuel boilers with long burning have become the most popular.

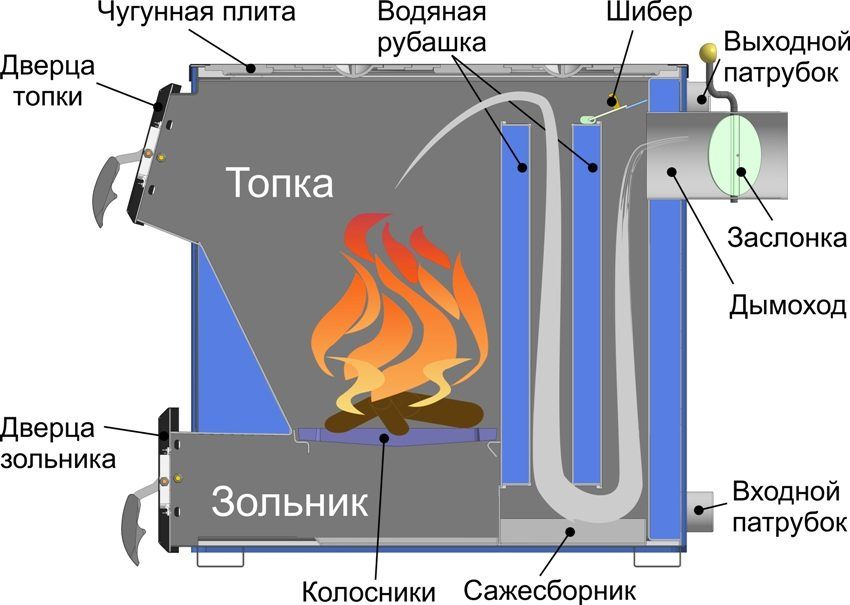

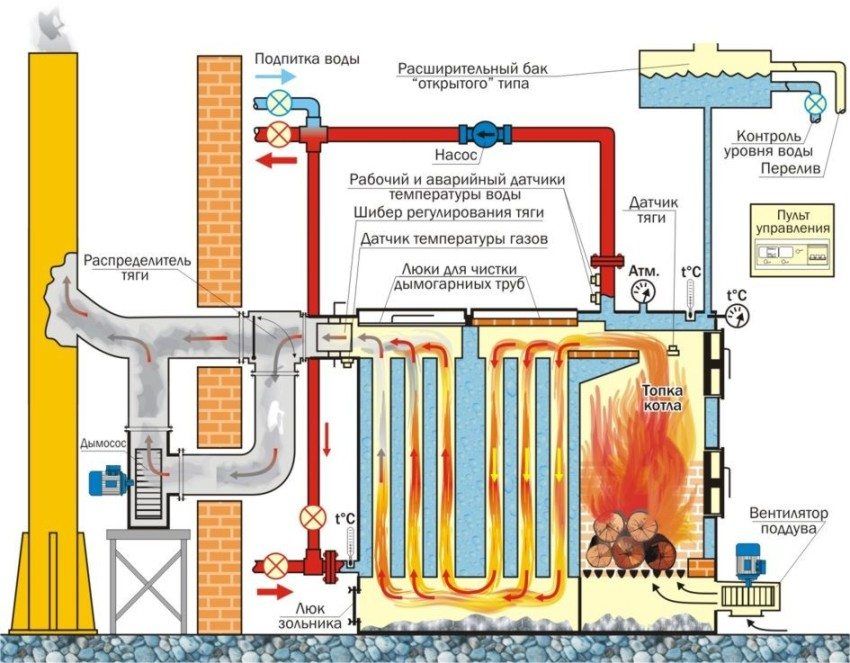

The principle of operation of solid fuel boilers and their device

Solid fossil fuels are the oldest source of energy for humanity. To abandon it completely, even in the modern world, is impossible. Moreover, besides firewood and coal today, many other types of combustible solids have appeared:

- peat briquettes – dried and compressed peat emits a lot of heat when burned;

- briquettes from waste wood production – compressed sawdust, shavings and bark of trees;

- birch coal – the same as for the barbecue;

- recycled garbage from landfills;

- fuel heating pellets – small fuel, obtained by pressing sawdust. Can be fed automatically;

- ordinary dry sawdust.

It is clear that all this fuel is obtained by recycling various wastes, which solves the problem of recycling in enterprises and goes along the “green” economy.

Helpful advice! The most affordable fuel, from the above, are sawdust. If you intend to use them for heating – make sure that they are with humidity less than 20%. Large indicators of this parameter will not allow pyrolysis gas to be generated, since most of the heating energy will go to dry the fuel.

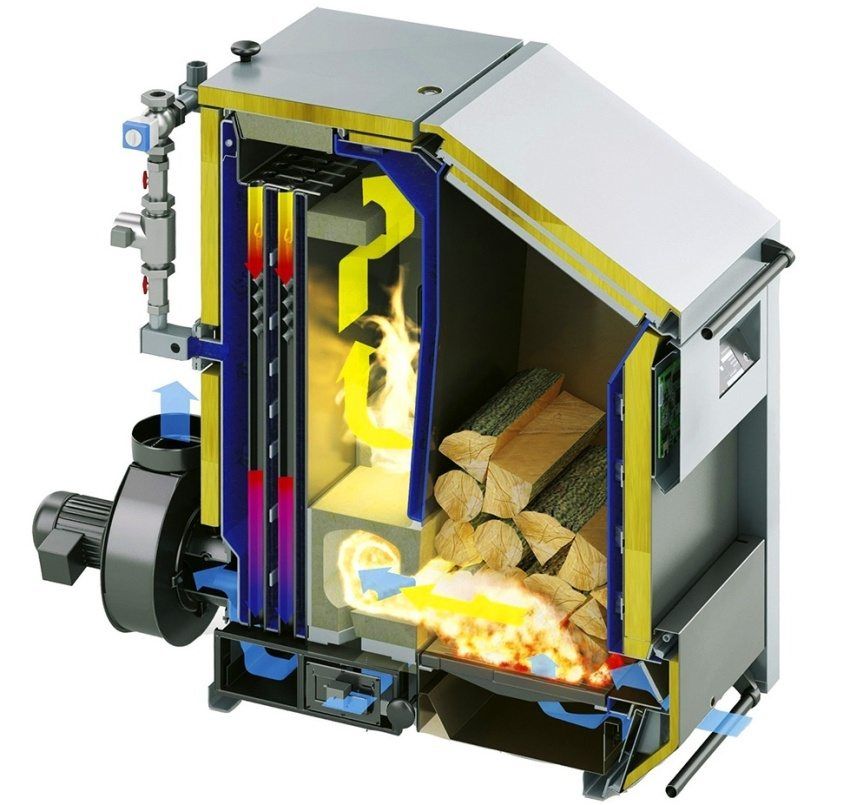

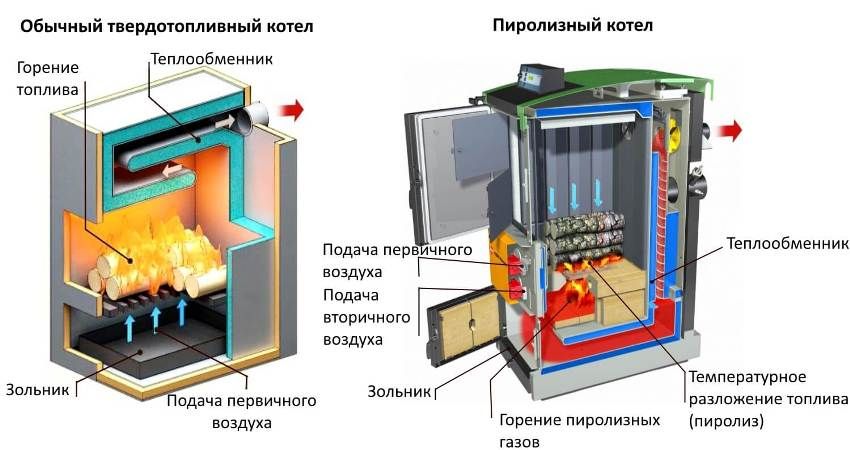

As a result of human activity, an enormous amount of waste is formed, which can be converted into high-energy fuel, which led to the appearance on the market of heating boilers for solid fuels of long-burning. Unlike conventional furnaces, these units work not on the combustion of the fuel itself, but on its decomposition as a result of heating. In the working chamber of such boilers, gaseous decomposition products of solid fuels are burned. Such a scheme of work is several times more efficient than conventional burning of fossil fuels. Pyrolysis gas, gives a large amount of energy.

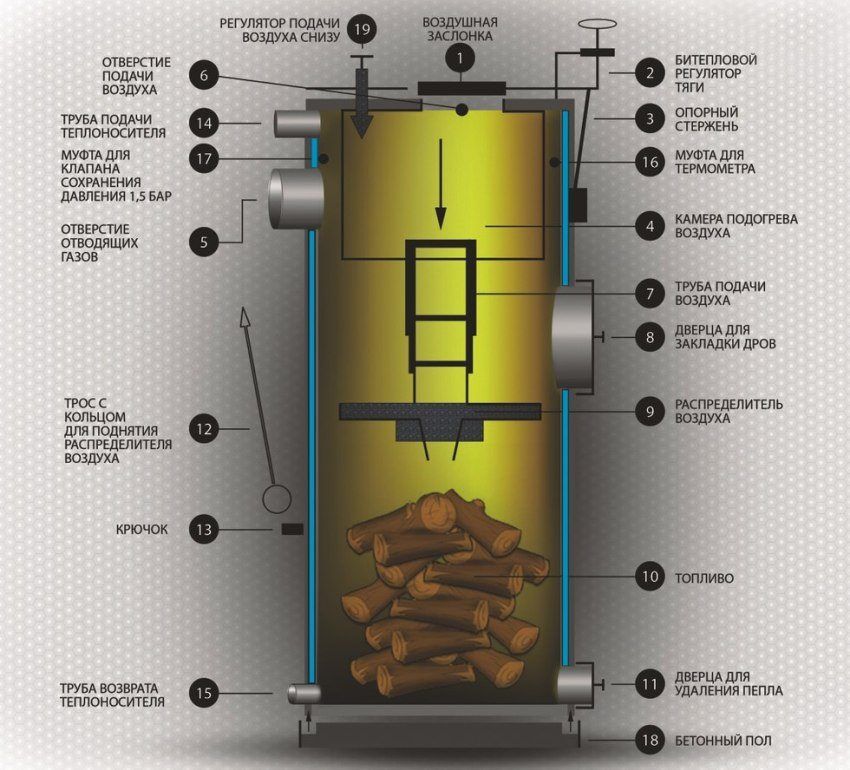

The device of such a gas generator is not very complicated. You can even build a solid fuel boiler with a long burning. The drawing of the simplest version looks as follows:

- a closed cylindrical tank, which has a hatch for laying the fuel, a blower and a hole for the installation of the chimney;

- Inside the tank there is an air distributor that creates a pyrolysis gas turbulence. It is attached to a movable telescopic tube. This whole piston-like construction puts pressure on the fuel from above. Combustion of gas occurs above the piston, and the fuel smolders under it;

- the heat exchanger is integrated in the upper chamber where the maximum temperature is reached.

Slow smoldering of solid fuel occurs in the lower chamber. It is achieved by adjusting the air supply to the pumper. The emitted gas intensively burns in the upper chamber and heats the coolant.

Helpful advice! You should not use the simplest design for the manufacture of the boiler, which will heat the residential house on a permanent basis. To do this, you must either purchase the finished product, or make a more complex and reliable option.

Solid fuel boilers for long burning can be indispensable in private homes, household buildings, garages and greenhouses. Especially they will be beneficial where there is a large wood processing industry, since the waste at such enterprises is given almost free of charge. These units are also needed in areas where there are regular interruptions in gas supply. Such installations have many advantages, but there is one important disadvantage – a very high cost. That is why today it is important to make your own solid fuel boilers for a long time. Drawings for this you can use different degrees of complexity. It depends on the skill level.

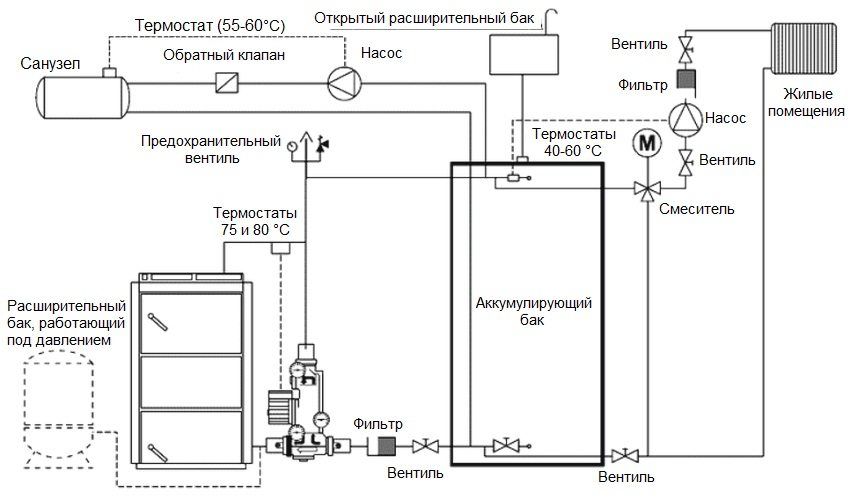

Water heating a private house with their own hands, schematic designs. Pros and cons. Distinction of natural and forced circulation of water.

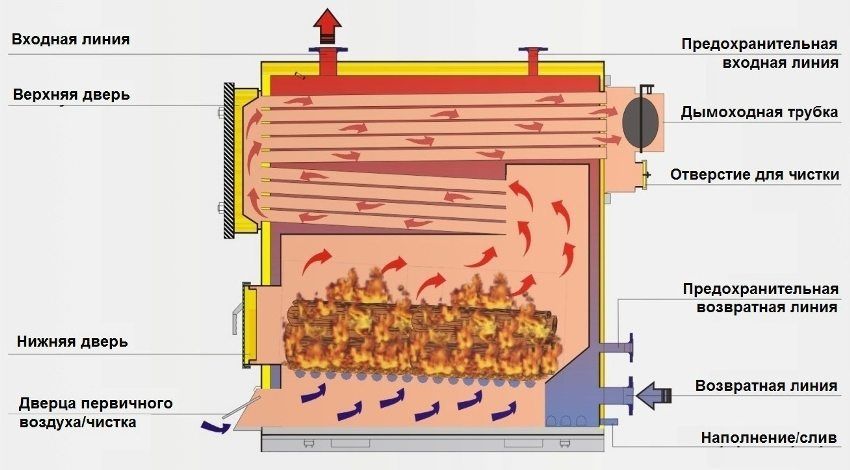

Before you start making the boiler, you need to decide on its design. Its choice depends on the purpose of the unit. If it is intended for heating a small utility room, a garage or a country house, then it is not necessary to make a water circuit in it. Heating of such a room will occur directly from the surface of the boiler, by convection of air masses in the room, as from a furnace. For greater efficiency, you can arrange a forced blowing of the unit with air using a fan. If there is a liquid heating system in the room, it is necessary to provide a device in the boiler circuit in the form of a coil from a pipe or other similar design.

Connection diagram of a solid fuel boiler to the heating system

The choice of option depends on the type of solid fuel that will need to be used. For heating with conventional firewood, an increased volume of the firebox is required, and for the use of small fuel pellets, it is possible to arrange a special container, from which granulated fuel is fed into the boiler automatically. For the manufacture of a solid fuel boiler long-term burning with your own hands, the drawing can be taken and universal. It is suitable for any type of solid fuel used.

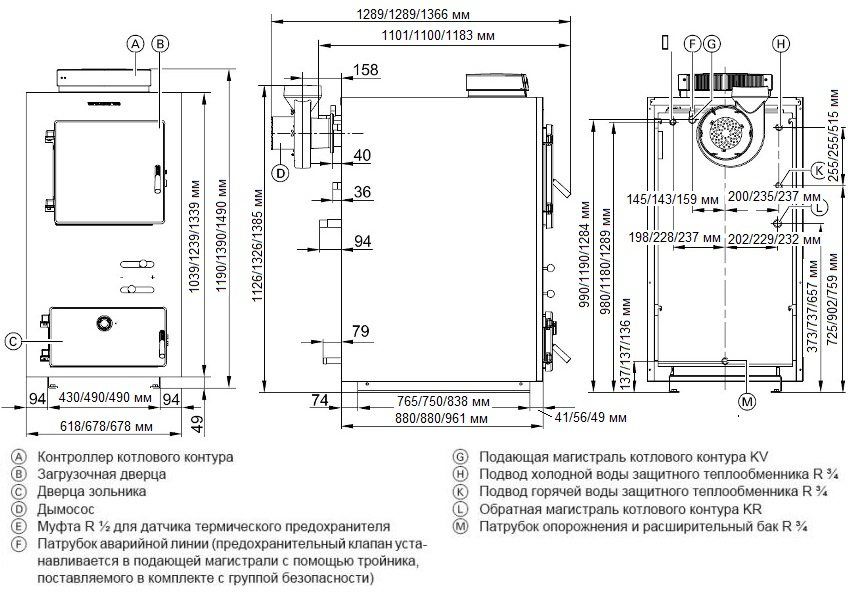

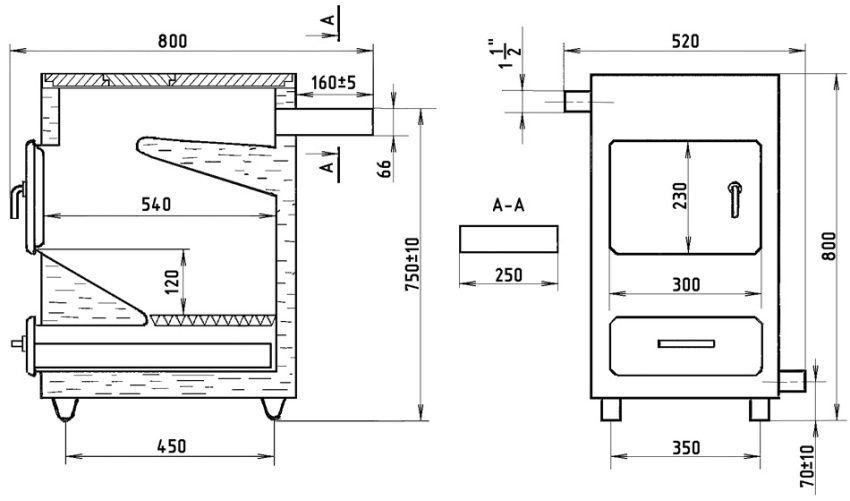

Let us tell step by step how and from what parts it is possible to make a heating boiler on solid fuel of long burning according to the proposed scheme:

- let’s prepare the place where the future unit will be installed. The base on which it will stand must be flat, strong, rigid and fire-resistant. The concrete foundation or a thick cast-iron or steel plate is best suited for this. The walls must also be upholstered with fire-resistant material, if they are wooden;

- We collect all the necessary materials and tools: of which we need a device for electric arc welding, a Bulgarian and a tape measure. From materials: sheet 4 mm steel; 300 – mm steel pipe with walls of 3 mm, as well as other pipes of 60 and 100 mm in diameter;

- in order to make a solid fuel boiler for long burning, it is necessary to cut a piece with a length of 1 m from a large 300 – mm pipe. It can be a little smaller if necessary;

- cut the bottom of the steel sheet across the pipe diameter and weld it, providing legs of channel length up to 10 cm;

- The air distributor is made in the form of a circle made of steel sheet with a diameter of 20 mm smaller than the pipe. In the lower part of the circle the impeller is welded from a corner with a shelf size of 50 mm. For this you can use a channel of the same size;

- From above into the middle of the distributor we weld a 60 – mm pipe, which must be higher than the boiler. In the middle of the distributor disc, cut a hole through the pipe, so that there is a through tunnel. It is needed for air supply. At the top of the pipe, a damper cuts in to allow adjustment of the air supply;

- at the very bottom of the boiler we make a small door, fitted with a latch and hinges, leading to the ash pan for easy ash removal. From above in the boiler we cut a hole for the chimney and weld a 100 – mm pipe into this place. At first it goes at a small angle to the side and upwards by 40 cm, and then strictly vertically upwards. The passage of the chimney through the ceiling of the room must be protected by the rules of fire safety;

- we are finishing the construction of a heating boiler on solid fuel of long burning by manufacturing the top cover. In its center there should be a hole for the pipe of the air flow distributor. Fit to the walls of the boiler must be very tight, eliminating the ingress of air.

Helpful advice! To ignite a custom-made solid fuel boiler of long burning, the drawing of which was presented above, it is necessary: remove the lid and raise the regulator, fill the boiler to the top with fuel and pour it with flammable liquid, put everything in place and throw the burning torch into the regulator pipe. When the fuel breaks out, reduce the air flow to a minimum so that it only starts to smolder. After that, the pyrolysis gas will ignite and the boiler will start.

“I work at a sawmill. Previously, drove home bitches and cutting carts. I learned about the solid fuel boiler long burning, read reviews and decided to do. Happened. Now the wood goes three times less, and the heat is the same. ”

Alexander Nikolaev, Syktyvkar

“I saw a wonderful cauldron with a friend in the garage. We repaired the car in the morning. He, as the wood in it put, so more until the evening and did not touch. I could not understand anything until he explained the whole scheme to me. Here, too, got the idea to put myself in the garage. A friend said give drawings.

Nikolay Platonov, Surgut

“If you decide to do, for example, at your dacha, a solid fuel boiler of long burning, reviews of which were found on the network, then do everything clearly according to the scheme in compliance with all safety rules. And then, my neighbor burned the cottage, when the boiler was installed in the holes ”.

Andrey Shirshov, Tyumen

The heating device described above will serve you faithfully, allowing you to save on energy. However, do not forget to do everything qualitatively, without departing from the scheme.