Polypropylene pipes are popular due to reasonable price and quality of material. Low thermal conductivity of the polymer maintains the temperature of the coolant. Low equivalent roughness of the inner walls of pipes does not reduce the flow rate. Simple assembly technology allows you to quickly mount heating in a private house made of polypropylene pipes with your own hands.

Technical characteristics of polypropylene pipes for heating

The abbreviation, with information about the operating parameters of the product, is applied to the pipe walls. The basic marking of polypropylene (PP) meets international standards:

- manufacturer’s logo;

- letter designation and supplement on product modification (PP-random, PPRC, PPs);

- conditional pressure (PN25 MPa) of the working medium;

- external diameter and size of the product wall;

- class of operation;

- the maximum allowable working pressure in bar, which indirectly indicates the service life of the product;

- product standard.

A description of the design features, purpose and scope of the product is given by the manufacturer in the product data sheet. The table, as an example, provides data on the products of the manufacturer VALTEC (Italy):

| Class | Place of application | Working pressure bar | |

| Fiberglass | Aluminum | ||

| one | Hot water supply, T = 60 ° C | 13 | 14 |

| 2 | Hot water supply, T = 70 ° С | ten | eleven |

| 3 | Heated floors, T = 50 ° C | 14 | 18 |

| four | Heated floors, T = 70 ° C | ten | 13 |

| five | Radiator heating (taking into account the type of pipe reinforcement: aluminum foil T = 90 ° C, fiberglass fiber T = 90 ° C) | 6 | 9 |

Products with an inner insert of aluminum foil are used primarily for heating. The reinforcement of polypropylene pipes with fiberglass also allows their use in radiator circuits, underfloor heating and hot water supply of private houses. However, pipes with an inner layer of fiberglass fiber allow a slight lengthening of the linear sections during heating and oxygen permeability.

Technical characteristics of reinforced polypropylene pipes (manufacturer VALTEC):

| Physical properties | Aluminium foil | Fiberglass fiber | ||||

| Diameter and thickness of the pipe wall, mm | ||||||

| 25×4.2 | 32×5,4 | 40×6,7 | 25×3.5 | 32×4,4 | 40×5,5 | |

| Inner diameter | 16.6 | 21.2 | 26,6 | 18 | 23.2 | 29 |

| Nominal pressure, PN, bar | 25 | 20 | ||||

| Weight per meter of pipe, kg | 0,262 | 0.446 | 0.880 | 0.235 | 0.378 | 0.590 |

| PPR density, g / cm? | 0.91 | 0.91 | ||||

| Filling the pipe, liters in 1 pgm | 0,217 | 0.353 | 0.556 | 0.254 | 0.423 | 0.660 |

| Specific heat at kJ / (kg *? C) | 1.75 | 1.75 | ||||

| Breaking force limit, MPa | 35 | 35 | ||||

| Oxygen permeability, mg / m? per day | ? | < 3.6 at 80? С | ||||

| Equivalent inner surface roughness, mm | 0.01 | 0.015 | ||||

| Linear increase in length 1 /? С | 3.1×10-five | 6.2×10-five | ||||

| Heat conductivity coefficient, W / (m *? С) | 0.24 | 0.15 | ||||

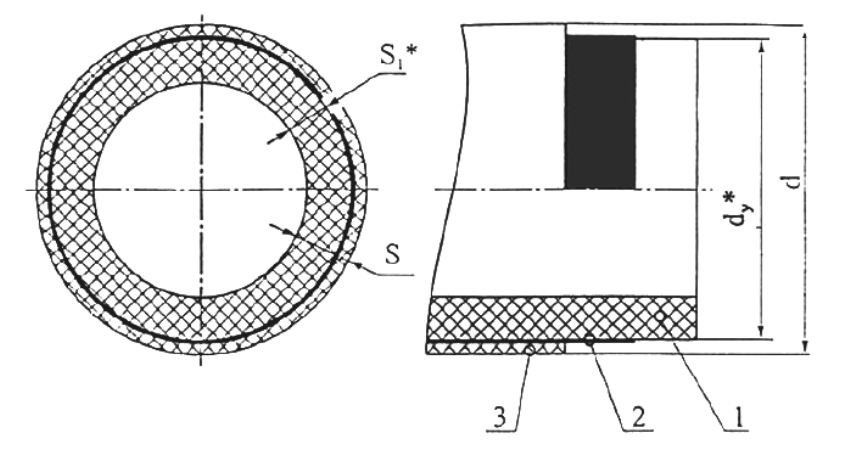

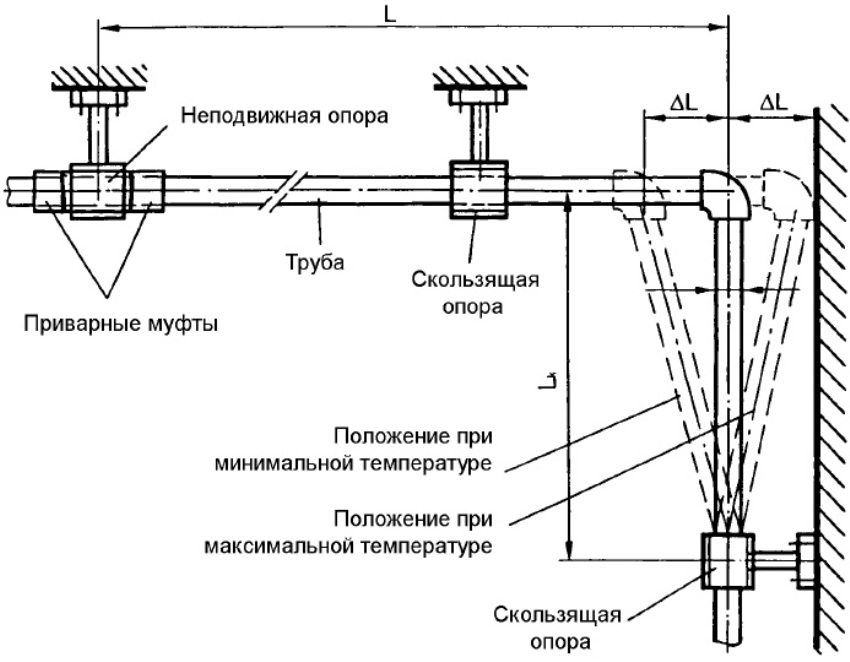

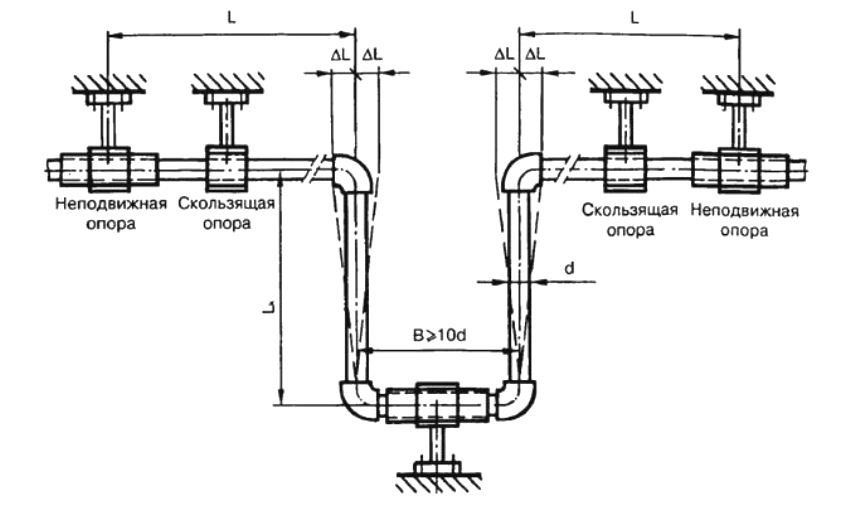

Fittings and valves for heating systems made of polypropylene are made from random copolymer pipes similar to the material of the pipes. Elements without thread are designed to be connected to the socket, in which the pipe is inserted into the body of the fitting. The inner diameter of the connecting parts (corners 90? And 45 ?, couplings, adapters, tees, crosses and cranes) corresponds to the outer diameter of the pipe. Linear thermal expansion leveling ready compensatory loops or welded structures of independent execution.

Clamps (single and blocks of clips), are designed to fix straight, horizontal or vertical sections of the pipeline along the walls. The fastener installation step (recommended by the manufacturer) depends on the pipe size and the quality parameters of the coolant. Clamps from similar materials are designed for mounting PP large diameter pipes. Fastening can be rigid or floating, a small gap will provide the possibility of free running during thermal expansion.

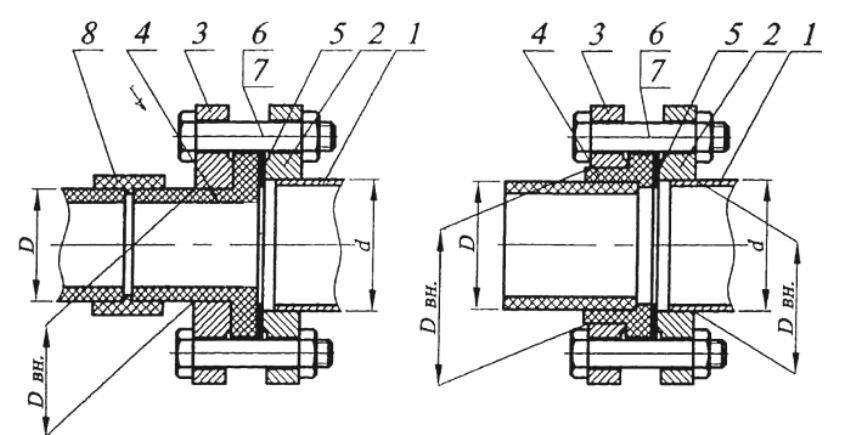

Connection to steel pipes or fittings is obtained by using combined fittings. Collapsible fittings (American) for the transition from metal to polymer are produced with internal or external threads of galvanized metal on the one hand, and propylene insert on the other.

A set of fittings and fittings is selected individually for each room in the house. The number and brand of fittings depend on the configuration of the heating system and the type of heating equipment.

Important! The passage of the PP pipes through the walls and interior partitions is made through a sleeve that allows the structure to shift during thermal expansion and prevent abrasion of the material. Between the surfaces of the inner corners of the walls and the turning point of the pipeline from the PP leave a gap of compensatory stroke. Increasing the length of the linear sections should not cause ultimate stresses in welded joints.

The cost of the product depends on the destination and manufacturer. Well-known domestic manufacturers specializing in the production of reinforced PP pipes: “Sinikon” and “YarInterPlast”.

Software pipes of the PN25 MPa brand use for heating. The price of polypropylene fiberglass-reinforced pipes is lower than products with an internal aluminum frame (approximately 10%). The difference is explained by the guaranteed product life, the permitted coolant temperature and the operating pressure of the system.

The average cost of polypropylene pipes for heating (price per meter):

| Diameter of pipe, mm | Producing country | Operating class / type of reinforcement | Price, rub / pgm |

| 25 | Italy | 5 / aluminum | 33.75 |

| 32 | Italy | 47.25 | |

| 40 | Italy | 79.50 | |

| 25 | Italy | 5 / fiberglass | 23 |

| 32 | Italy | 42.25 | |

| 40 | Italy | 60.50 | |

| 25 | Turkey | 4 / fiberglass | 21.99 |

| 20 | Turkey | 5 / aluminum | 21.52 |

According to professional reviews, polypropylene pipes for heating are the best option for autonomous systems. Homogeneous solder construction without threaded connections and metal fittings are easy to install and convenient to use.

Piping transmits the flow of heat energy from the boiler to the heating devices. Water is a traditional heat carrier of heating systems for country houses. Amorphous polymer to aggressive environment under the action of high temperatures is the key to durability of pipes. The inner surface of the pipe provides negligible resistance to directional flow. Impurities contained in the coolant in a suspended state (organic matter, compounds of hardness salts, scale, sand particles) do not form deposits on the walls of polypropylene pipes. The products reinforced by aluminum exclude access of oxygen to system of heating from the pipeline. The layer of foiled metal reduces the risk of corrosion of the boiler heat exchanger, increases the service life of the system as a whole. Numerous materials, schemes, video heating with their own hands in a private house can be easily found on the Internet.

Emergency freezing of pipe wiring does not threaten the destruction of polypropylene pipes. After defrosting the water, the material restores its original properties. However, it should be remembered that it is impossible to warm PP pipes using open fire!

The increase in the linear dimensions of the pipe during heating is perhaps the only significant drawback of polypropylene products. Reinforcement with aluminum foil reduces many times the rate of thermal expansion and increases the class level of pipes.

Important! In country houses, antifreeze is not used for heating systems made of propylene (the allowed non-freezing material of pipes for heat carrier is steel, copper, brass and plastic, with a rubber outer contour).

Considering that the optimal pressure in the household boiler circuit is 1.5–2 bar, the heat source is as close as possible to the consumer and the temperature in a residential house does not fall below 5 ° C, we conclude: aluminum-reinforced polypropylene is an ideal material for pipe installation in a private house.

Installation of heating systems made of polypropylene is carried out at a room temperature of at least 5 ° C. The consumable for heat sealing (accessories) must be appropriate for the intended use (PPRS).

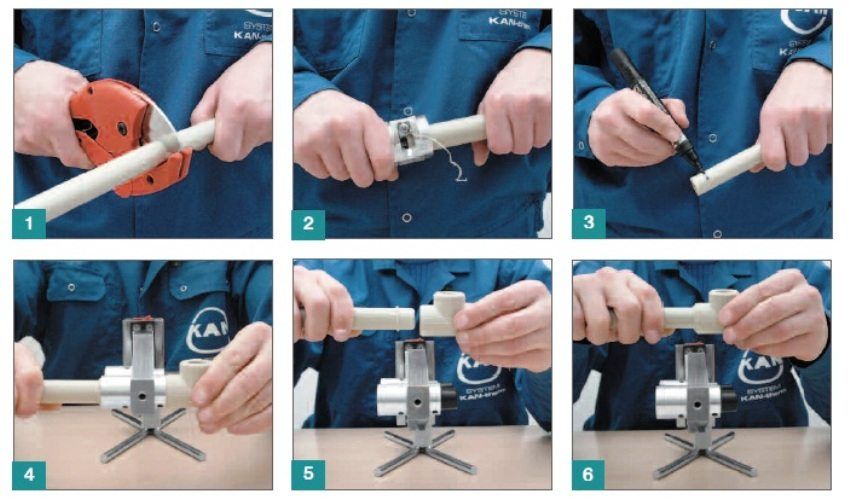

The sequence of operations in the manufacture of components at the work site:

- the pipe cut is made with special scissors by preliminary marking on the body;

- preparation of the cut surface includes chamfering at a depth of 1 mm at an angle of 30 ° and degreasing the end of the pipe with acetone;

- mark the boundaries of melting – at the end of the pipe with a pencil put a restrictive risk;

- processing of working surfaces of a soldering iron;

- heating the instrument;

- the melting of parts (with exposure time ranges of the diameter of the pipe on the passport of the device, and the alignment of parts with the body of the iron);

- docking the node without offsets and rotation of elements;

- cooling.

Size of embedded pipe section for heating:

| Diameter, mm | 20 | 25 | 32 | 40 | 50 |

| Distance from the end, mm | 14.5 | sixteen | 18 | 20.5 | 23.5 |

The time limit for the manual thermal welding process (standard values):

| Outer diameter of pipe / internal diameter of fitting, mm | Time with | ||

| Contact with the nozzle | Docking | Cooling | |

| 20 | five | four | 120 |

| 25 | 7 | four | 120 |

| 32 | eight | 6 | 240 |

| 40 | 12 | eight | 300 |

Electric current in a soldering iron for polypropylene – 36V. The operation of the instrument from the household network requires the presence of a safety shut-off machine.

After cooling the joints, check the straightness of the joint, the uniformity of the weld bead and the absence of welding defects. The number of connecting nodes, when following the rules of resistance welding, does not affect the throughput of the system. Low resistance in welded parts due to the physical properties of the material and the method of connection without reducing the flow area of the pipe. Hydraulic tests for strength and density of the PP pipe system are carried out 16 hours after welding.

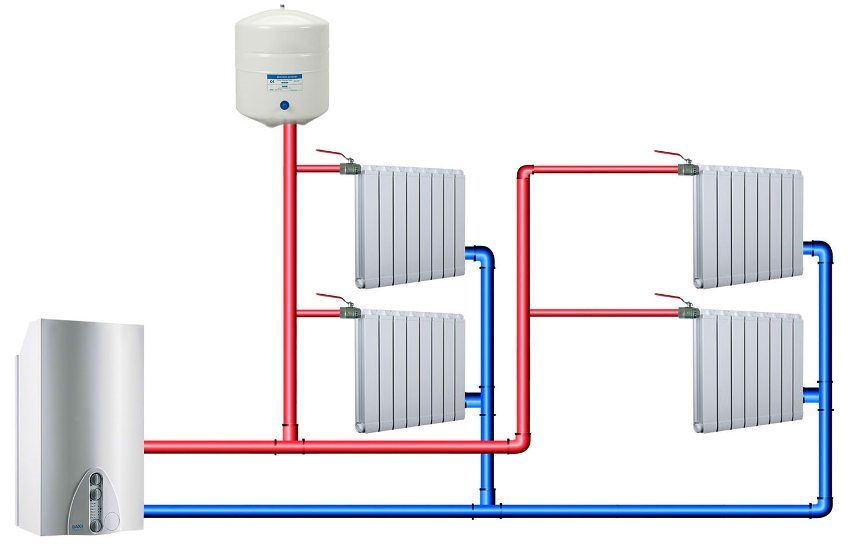

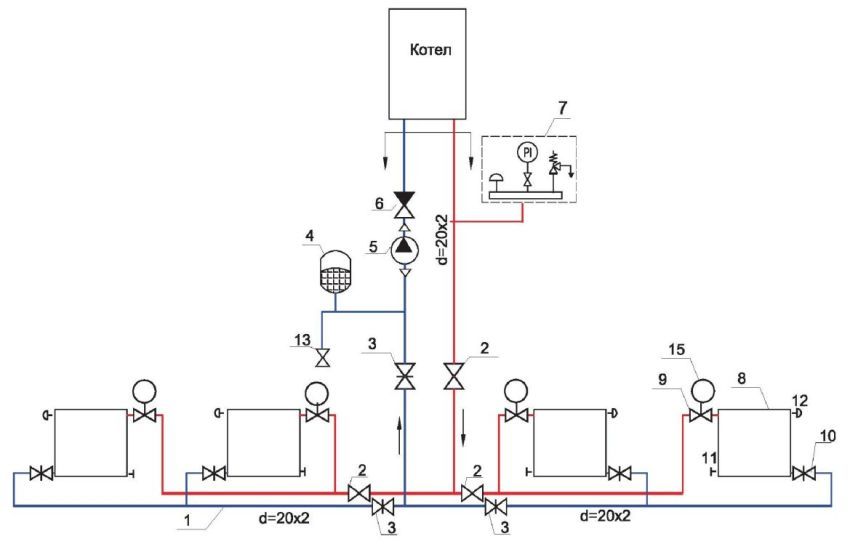

Non-volatile or pressure, one-or two-pipe scheme is chosen based on considerations of efficiency and comfort. Traditionally, private houses are equipped with horizontal wiring with independent floor contours. The heating system of small houses with natural circulation is a chain of serial connection of radiators. Efficient heat supply of a large area house is carried out by two-pipe wiring with forced movement of the heat carrier.

High-quality installation and equipment piping are impossible without calculating the throughput and determining the diameter of pipes at each site. The coincidence of the calculated and actual costs will reduce heat losses, ensure stable, reliable and silent operation of the system.

Using an online calculator, you can make a hydraulic calculation for a one-pipe water heating scheme of a private house with your own hands. The programs DanfossCO and OvertopCO make calculations for in-house heating systems with natural circulation. Calculations in Excel Online are summarized in a convenient tabular form. Filling the source data column and selecting the necessary constants (the graphs are highlighted in color), we obtain the calculation results.

The classic method of arranging the heating system is a single pipe wiring. Clarify the installation will be able to themed video of the heating of a private house made of propylene. Doing your own hands can quickly, accurately and cheaply carry out the strapping of equipment.

Systems with one pipe wiring and natural circulation work under the action of the forces of aggression. The slope when laying pipes and installing a heat generator below the level of residential premises will increase the speed of the flow. However, when the radiators are connected in series, it is impossible to evenly distribute heat. The rooms removed from the boiler warm up badly, there is a danger of the circulation and boiling up of the boiler water.

The problem is solved by the heating device of a private house with their own hands in the “Leningradka” scheme. Videos can be found on the net.