Solid fuel boiler wood with a water circuit installed in the house with the permanent residence of people. The period between the tabs of the fuel of a classical unit does not exceed 4–8 hours. A working boiler is not left unattended. To change the time of the firebox, modernized boilers of long burning on wood with their own hands allow a 24-hour load – the optimal period of the unit operation without intermediate fuel charging.

Solid fuel boilers for heating a private house

The basic models of long-burning boilers with a water circuit on wood for a house are distinguished according to the material used, the design of the firebox, the heat exchanger, the chimney, the method of loading and burning of fuel.

Wood burning boiler with a long water circuit is equipped with a tubular (vertical) register or a heat exchanger of the jacket type. Body design virtually eliminates the possibility of boiling water in systems with natural circulation.

Steel wood-burning boiler long burning for heating a house has a low thermal inertness. The boiler circuit of heat-resistant steel withstands sudden changes in temperature and pressure in the system. The lack of material – sensitivity to corrosion, which increases the temperature stress of the metal. The between-repairs period of operation of the unit from steel – 15 years.

The walls of the cast-iron heat exchanger of a wood boiler for heating a private house with batteries heat up and cool down for a long time. The brittle alloy is not intended for critical changes in system operating parameters.

The advantage of cast iron due to the amorphous material to oxygen corrosion. The life of the boiler with a cast iron heat exchanger, with proper operation of the unit, reaches 25 years.

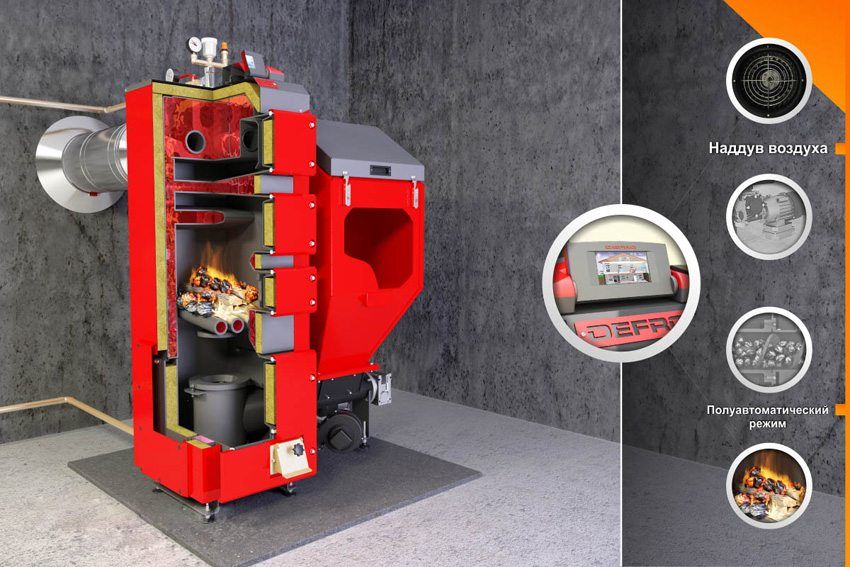

The principle of operation of the long-burning unit is forced, consistent, top-down smoldering of wood, in which methane, carbon monoxide and hydrogen are emitted. Lack of oxygen slows down the rate of flame propagation. Additional heat energy is generated when burning flue gas. The stream of leaving combustion products washes the surface of the heat exchanger at the outlet of the boiler. The design allows the loading of firewood once a day.

Table 1. Price of long-burning boilers for solid fuels:

| Brand of boiler (country of origin) | Price, rubles |

| Zota Mix – 32 (Russia) | 38700 |

| Stropuva Mini S8 (Baltic) | 58240 |

| Solid propellant copper of long burning OOROR N 412 (Czech Republic) | 51731 |

Note! The average price of long-burning boilers for wood for a house is 50 thousand rubles. The quality of the latest domestic developments of solid fuel boilers are worthy of competition to foreign counterparts.

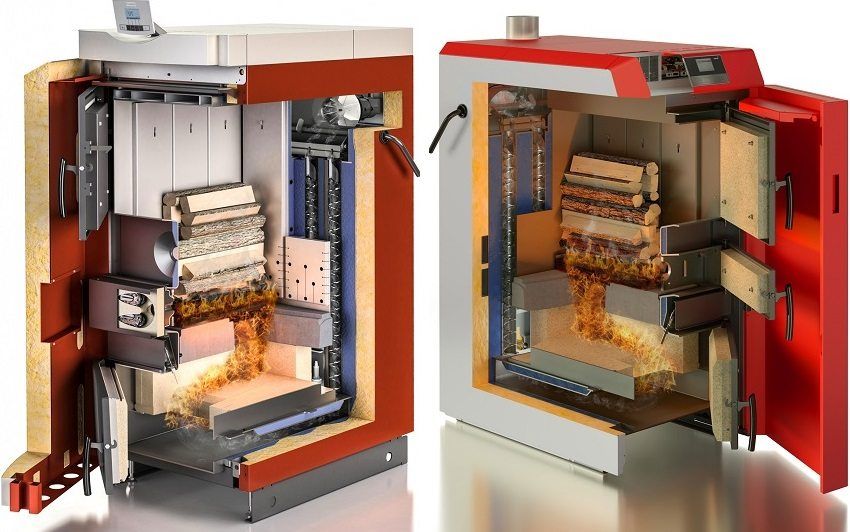

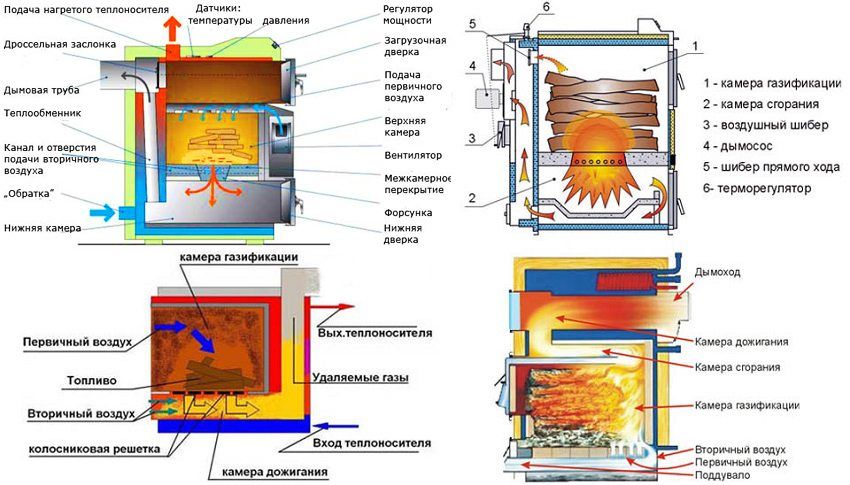

Pyrolysis units – one of the types of long-burning boilers. Phased separation of the combustion process increases efficiency and prolongs the operation time of the gas generator. The pyrolysis boiler furnace is separated by a special nozzle. In the first compartment, under the action of high temperatures, the laying of firewood emits a combustible gas. The second serves to burn down the products of decomposition of wood. A minimum amount of ash is formed in the ashpit, and the chimney does not overgrow with soot deposits.

Gas generating plants are designed for heating systems of residential buildings with an area of more than 100 m ?.

Table 2. Price of pyrolysis boilers of long burning with a water circuit:

| Mark | Price, rubles |

| Solid propellant pyrolysis boiler MS-16 (Russia) | 132,000 |

| Steel pyrolysis copper of Buderus Logano S171-22 W (Czech Republic) | 202250 |

| Solid fuel pyrolysis boiler Bourgeois – K STANDARD-20 (Russia) | 49800 |

| Gas generator boiler KO12 (Russia) | 52494 |

Pyrolysis wood boilers work up to two days on a single load of fuel. The cost of the product depends on the brand of the manufacturer, the power and degree of equipment of the unit with automatics.

Boilers long burning on the wood with their own hands, loading 24 hours

The boiler power is selected in accordance with the structural characteristics of the house (area, total heat loss) and the climate zone of the place of residence. As a rule, the efficiency of a homemade long-burning boiler on wood does not exceed 80% (i.e. one fifth of the heat from the combustion of fuel is lost in the boiler).

The lack of thermal power stimulates the generator in intensive burning mode. Constant peak loads lead to excessive consumption of firewood, excess heat loss by half and premature wear of the boiler.

The type of wood, the shape and length of firewood determines the size and equivalent area of the combustion chamber. The specific and bulk density of the load, the heat that the wood emit during combustion – reference values. The calculation of the load volume will help to calculate the fuel consumption for the season, to organize the storage of fuel.

Important! The quality of firewood affects the burning process. The high content of tar in the wood of conifers and high humidity of freshly chopped wood reduces the efficiency of the boiler. Incomplete combustion of raw wood leads to the deposition of soot and tar on the surface of the water circuit, the walls of the firebox and chimney. The metal is oxidized, transfers heat worse, burns quickly.

Table 3. Volumetric heat of combustion of wood of different species:

| Type of wood (humidity not more than 20%) | Calorific value, kWh / kg | Specific density of firewood, kg / m? | Bulk density, kg / dm? | Combustion temperature, ° С |

| spruce | 4.3 | 450 | 1.4 | 600 |

| pine ordinary | 4.3 | 520 | 1.6 | 660 |

| Birch tree | 4.2 | 650 | 1.9 | 890 |

| oak | 4.2 | 720 | 2.0 | 900 |

Consider an example of calculating the volume of the boot chamber of a wood boiler.

Initial data:

- boiler power 10 kW;

- the volume of one load must ensure the operation of the unit during the day;

- fuel – birch firewood, log length 0.60–0.65 m;

- wood moisture 20%.

Options for heating a country house: the choice of the boiler. Advantages and disadvantages of water heating from a wood burning stove. Features of solid fuel, gas, electric units: description and prices.

During the combustion of 1 kg of birch wood, 4.2 kW of heat is released. The specified power (10 kW) will ensure the burning of 2.4 kg of firewood per hour (10 / 4.2 = 2.81).

A cubic meter of birch wood weighs 650 kg. Hourly fuel consumption will be? 0.004 m / h (2.4 / 650 = 0.0037).

Weight of a bookmark that a grate with a nozzle must withstand? 60 kg (2.381×24 = 57.144).

Birch firewood does not fit tightly, so the volume of the bookmark will increase 1.9 times – to 0.008 m? / H (0.004х1.9 = 0.0076).

By condition – loading 1 time per 24 hours, respectively, the volume of fuel is 0.2 m? (0.008×24 = 0.192).

If we take into account the length of logs 0.6–0.65 m, then the optimal depth of the firebox will be 0.7 m.

We take the height of the laying of fuel 0.6 m. The width of the furnace 0.5 m (0, 2 / 0.7 / 0.6 = 0.476).

The working size of the firebox of a wood boiler for heating a house (area 80 m ?, birch firewood) is 0.7×0.6×0.5 m. The overall dimensions of the finished boiler will double, taking into account the thickness of the casing, the size of the heat exchanger, air and the afterburner chamber, ash pan, channels to remove flue gases.

Adjustable and balanced burning will reduce the rate at which the flame spreads naturally. The limited supply of primary and secondary air to the firebox will ensure the lack of oxygen and extend the operating time of the home-made boiler 1.8 times. Due to this, it is possible to reduce the estimated consumption of firewood and, consequently, the size of the unit.

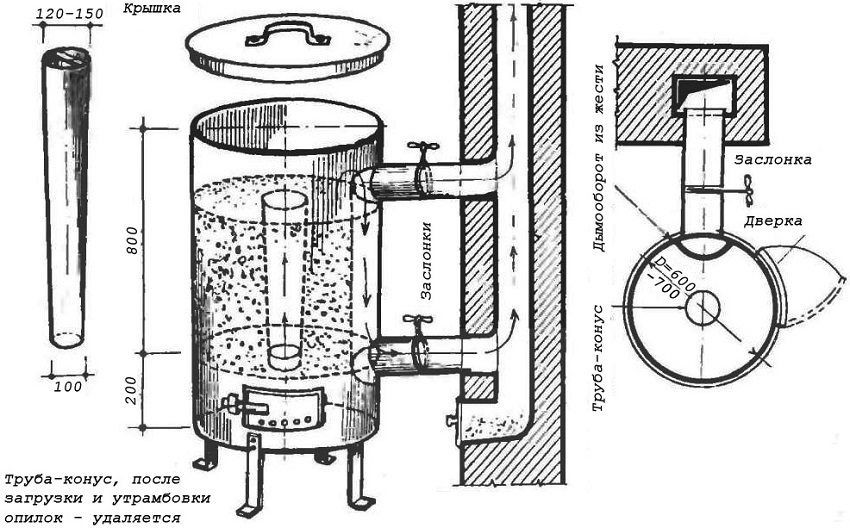

The boilers of long burning are assembled with their own hands from sheet steel (thickness 4 × 6 mm), thick-walled pipes (DN 300 mm) and cylindrical tanks of suitable size. The simplest design (“Slobozhanka” or “Bubafonya”) is collected from a gas cylinder or barrel. The principle of the device copies the Baltic boiler “Stropuva”.

The capacity of the vertical furnace is used for top-down burning of firewood. The process accompanies the uniform compaction of the charge, the emission and the after-burning of wood gases, and the removal of combustion products into the chimney.

Primary air to the burning mirror is fed through a vertical pipe. Static or telescopic construction is mounted in the upper wall of the boiler. The piston axis runs in the center of the cylindrical firebox. The gap between the collar and the primary air supply pipe is drawn up with a welded rim that provides free movement of the rod and minimal air inflow into the air chamber for the burning of wood gases.

Combustion of pyrolysis gases increases the efficiency of the boiler. A flap cover at the top of the pipe controls the air intake. Bottom is welded disc with blades that cut through the air flow in the combustion zone. The material for the distributor is chosen taking into account the heat capacity. The diameter of the disk is slightly smaller than the size of the firebox.

Constructive proportions of the “Bubafonya” boiler:

- the optimal case diameter is 300 × 800 mm;

- the height of the boiler is in the range of 3 × 5 diameters;

- wall thickness 4 × 6 mm;

- disc diameter less than the cross section of the combustion chamber by 10%;

- the thickness of the disk is inversely proportional to the diameter (a heavy pancake pushes the burning zone and extinguishes the flame, a light one – will lead to the reverse burning effect);

- curved blades form a directed turbulent flow of air for the combustion of pyrolysis gases;

- the diameter of the air supply pipe is taken as 0.55 from S (the cross-sectional area of the flue outlet pipe);

- the gap between the tube and the collar does not exceed 2.5 mm;

- the height of the air intake pipe (in the lower position) rises above the collar by 150 mm.

The cross-sectional area of the chimney pipe at the exit of the long-burning boiler is determined by empirical formulas:

S = 1.75xN (m?), Where

S is the cross-sectional area of the outlet (cm? Or m?);

N is the boiler thermal power (kW / h);

1.75 – empirically derived coefficient (m? H / kW).

N = m * qw (kW / h), Where

m is the mass of firewood of one load (kg);

qw is the specific heat emission of firewood of a certain humidity (kW / kg).

The load mass for improvised long-burning boilers on firewood is determined by the working volume of the firebox (Vk) and the specific weight of firewood (md):

m = Vk * md (kg), Where

Vk =? D? / (4 * hт) (dm?), Where

hт is the height of the loading chamber.

Table 4. Balanced size of elements in the primary air distribution system for the Bubafon boiler:

| The diameter of the boiler furnace, mm | Disk thickness, mm | The height of the guide ribs of the air distributor, mm |

| 300 | 8-10 | 40 |

| 400 | 6-8 | 50 |

| 600 | 4-6 | 60 |

| 800 | 2.5-4 | 80 |

Note! It is not possible to place the tubular heat exchanger in the combustion chamber. An external cylindrical body of larger diameter or a structure that is built into the chimney is required.

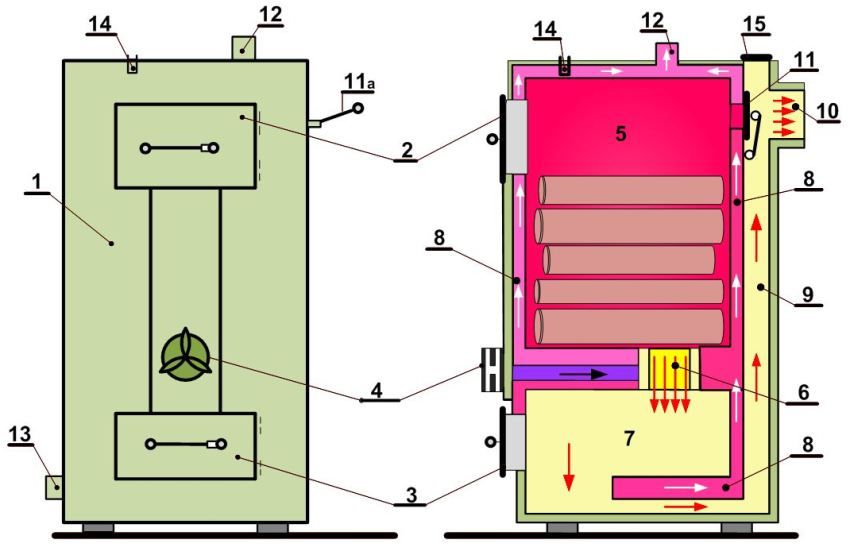

Self-made pyrolysis units are installed to heat a large area of houses. The design of the furnace, nozzles and smoke channels complicates the assembly of improvised gas generators. Forced circulation of the coolant and air supply to the combustion zone means the dependence of the boiler operation on external factors. Reducing the risk of accidental breakdown of the boiler allows the gate to release thermal energy and a jacket-type heat exchanger.

The boiler body is welded from thick-walled (4 × 5 mm) sheet steel. Loading firewood – front. Thermal radiation is transmitted to the arch of the boiler, the side walls of the chamber and heats the air entering the combustion zone. Density and tightness of the combustion chamber provides a bolt with a reflector and a turning bolt on the loading and ash hatches. Air is forced into the combustion chamber by a fan.

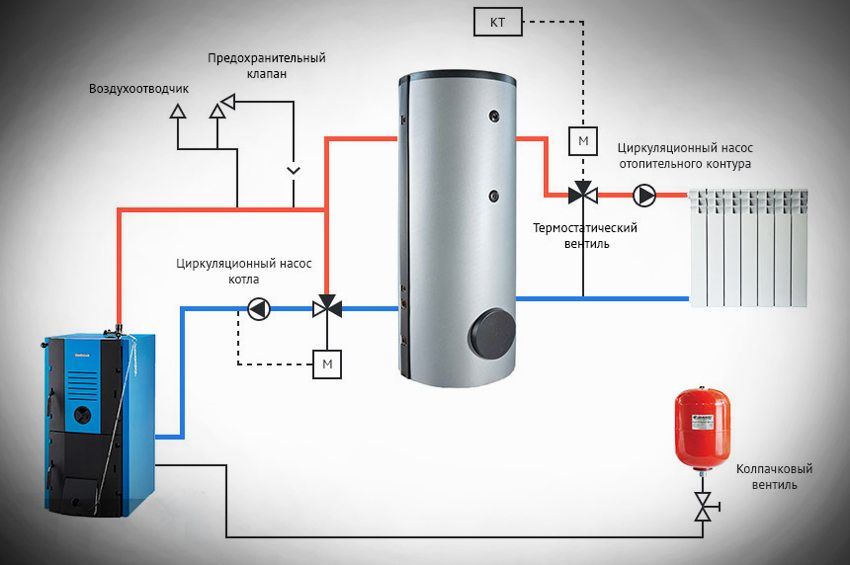

The shirt of the heat exchanger completely covers the firebox and partially the afterburner of the pyrolysis gases. The gap (3? 5 cm) is filled with water. The heat exchange of the rear wall is increased: on the one hand, the heat exchanger is bordered by the firebox, the other wall of the jacket is in contact with the flue duct. The heat exchanger integrated in the direction of the flue gases lowers the temperature of the outgoing flue gases to 100 ° C. The internal volume of the boiler circuit take 5? 25% of the total capacity of the heating system.

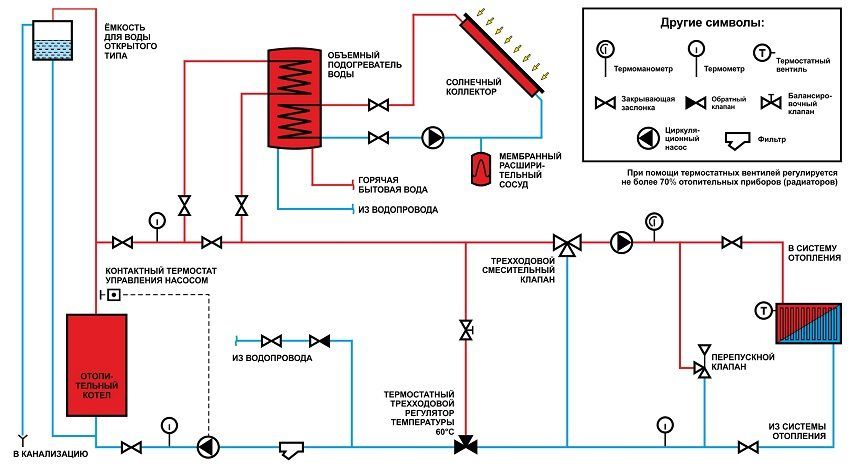

The coolant supply pipe to the consumer system is located at the top. Inset return pipe – bottom. Cooling the return of the coolant below 65 ° C, dangerous condensation of acid condensate on the walls of the heat exchanger, which destroys the steel. With a small boiler power, the temperature between the flow and return lines is equalized by installing an overflow valve. The boiler circuit of a large house is supplemented with an elevator unit and a circulation pump.

The grate in improvised long-burning boilers serves as a support for the fuel load. The red-hot firewood lies on the grates, lined with fireclay. Nozzles in the body of the grate serve as a nozzle, through which the combustible gas enters the afterburning zone of the fuel.

Ash and ashes wake up in the ash pan. Low-power boilers, with a uniform distribution of heat load over the mirror, fit standard cast iron grates.

The products of combustion enter the channels and through the mouth of the chimney out of the boiler (the formula for the cross-sectional area of the mouth of the chimney is given in the example above). The adjusting gate of the chimney is opened if necessary.

The design allows re-loading of fuel without completely extinguishing the boiler or forced release of thermal energy during a power outage. Red-hot wood gas leaves the firebox, bypassing the afterburner chamber and chimney channels.

The cross section and height of the chimney provides for the operation of a non-volatile homemade boiler on a natural draft. Normal draft pyrolysis boiler will provide a chimney height of 6 m.

The obtained data reflect on the scale drawing of the long-burning boiler with their own hands, according to which the volume and estimated amount for the purchase of consumable material is determined.

Important! If you do not manage to figure out the calculation of the boiler parameters yourself, then you should seek the help of professionals. Specialized online resources offer for the manufacture of their own hands pyrolysis boiler long burning drawings. Video tutorials, with detailed explanations of the installation, are attached to the technical documentation kit.

Independent manufacture of the boiler implies the availability of skills and experience in the production of welding, electrical and plumbing work. The knowledge of physics, heat engineering, materials science, the rules of installation of heating systems is useful.

Observance of safety practices and methods is necessary. For the assembly of the boiler you need an equipped room and tools.

Material for the manufacture of pyrolysis boiler:

- sheet steel with a thickness of 6, 5 and 4 mm (firebox, heat exchanger shirt and body);

- corner with the sides of shelves 50 mm (frame stiffening ribs);

- steel pipe (strapping heat exchanger with a heating system);

- suitable cast iron grate or round rod with a diameter of 20 mm;

- chamotte brick;

- centrifugal fan;

- ready-made doors with a reflector, mount, handle and lock;

- security group (temperature sensor, pressure gauge).

Welded parts are marked with chalk (joint, part number, dimensions). Specialized organizations offer services for cutting material at the place of purchase.

Tools for the manufacture of the boiler:

- DC welding machine;

- electrodes (diameter 3? 5 mm);

- electric drill;

- angle grinders (for a large circle of 230 mm and a small 125 mm circle);

- caliper, tape measure, level.

The assembly of the boiler start with the inner shell. The quality of the welds should ensure the strength and density of the structure that is in direct contact with the coolant.

Pyrolysis boiler for autonomous heating system is located in a separate specially adapted, protected from fire, the room. The boiler room is equipped with a ventilation system. The unit must be at least 20 cm away from the walls.

The standard weight value for improvised long-burning boilers on wood is 250 kg / m ?. Compliance with the conditions allows the installation of the unit on a flat, stable surface without a foundation. The area of the installation site is taken out beyond the projection of the housing of the unit by 15 cm (30 cm in front of the furnace door).

The floor is covered with asbestos or basalt cardboard (thickness 4 × 6 mm). A sheet of galvanized roofing iron (thickness 2 mm) is placed on top. Direct contact of the floor with the body excludes support structures – boiler legs.

The surface of the chimney must be covered with heat insulation. Insulation will prevent sudden temperature changes and the formation of condensate in the chimney. The thickness of the insulation layer depends on the temperature of the flue gases leaving. It is advisable to use a stainless steel sandwich pipe that is resistant to aggressive environments. In the absence of natural traction install the exhauster.

The aesthetics of handicraft production is inferior to the design of factory models, but the self-assembled unit meets the requirements of a particular heating system. Do not forget that the manufacture of the boiler of long burning according to the finished drawings (video) with your own hands will reduce the costs of its arrangement at least 2 times.