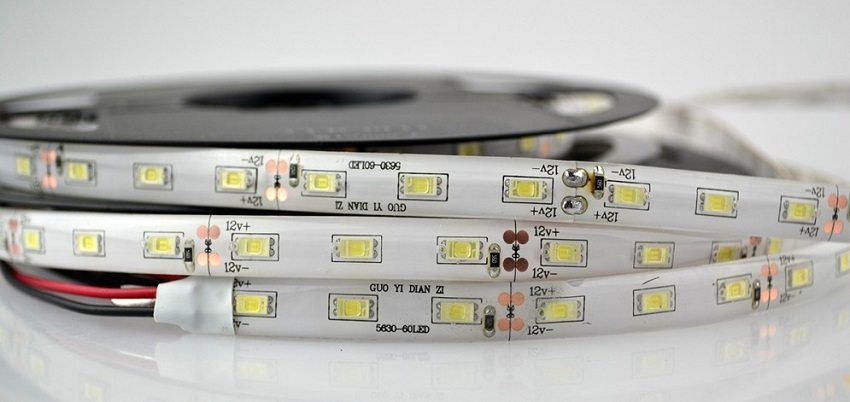

Using LED lighting in the interior, it is important that its work is stable, durable and does not adversely affect human vision. Correct functioning of LED devices is provided by voltage converters, which should be selected by performing some calculations. The correct power supply for the 12V LED strip protects the LEDs from voltage drops and premature loss of luminescence quality.

Types of power supply for LED strips 12 volts

Unlike conventional incandescent bulbs, LED designs can not be connected to 220V. They are available with a supply voltage of 12V or 24V. As a highlight in home interiors, LED tapes 12V are most in demand. To obtain the required voltage, special adapters are used – power sources that convert the voltage in the 220V network to the required value of 12V.

Before choosing a power supply for LED strip, you should be familiar with their types and characteristics. Stabilizers for LED products differ in the following criteria:

- power – 5; 15; thirty; 60; 100; 150; 200 and 350 (W);

- functionality – provide only power, with built-in dimmer (dimmer) and / or with remote control;

- cooling system – with active and passive cooling. When the system is active, a fan is emitted into the case that emits a certain noise, which can cause discomfort;

- degree of protection – there are models of hermetic and untight;

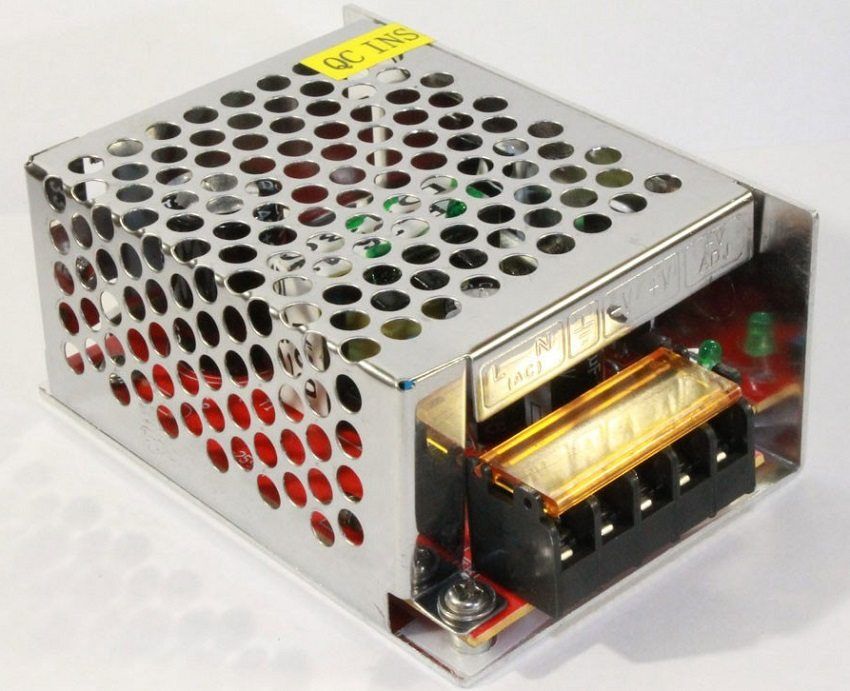

- housing design – plastic, aluminum sealed for rooms with a high level of humidity, metal with perforations and contact pads (used for dry rooms and requires installation in a closed place to avoid dust).

Voltage stabilizers are an indispensable element of high-quality lighting, ensuring maximum efficiency of LED light sources. They supply the LEDs with electricity for the required parameters, protecting them from possible voltage surges and premature failure. Thanks to power supplies, LED strips emit a uniform glow without flickering.

Power supply for LED strip 12V: calculation and connection of the device

To understand what kind of power supply is needed for the LED strip, it is necessary to make certain calculations, taking into account not only the output voltage, but also the amount of current delivered to the load. Therefore, for each particular backlight, it is necessary to calculate the total value of the current consumed by all the LEDs in the tape.

Options for calculating the power supply for LED strip

Before calculating the power supply for the LED strip, it is necessary to familiarize yourself with the accompanying documentation for the product, where the consumed current of one linear meter is indicated. In the absence of such data, the calculation can be made independently.

For example, we calculate the total number of LEDs for a 12V tape with a length of 15 m, a density of 30 LEDs of the type SMD 5050 per meter: 15 (m) x 30 (pcs.) = 450 pcs. Considering that each SMD 5050 LED consumes a current of 0.02A (this value is given in the table of diode parameters), the total current consumption of the entire tape segment is 9A (450×0.02 = 9). Consequently, a 12V power supply will be needed with a current carrying capacity of 9A.

Helpful advice! Overall power supply is quite difficult to hide in the overfill design. Therefore, to illuminate the ceilings, it is not recommended to use ribbons with a high density of LEDs, under which powerful converters are needed.

When calculating the power supply unit for the LED strip, multiply the voltage and the resulting current value: 12Вх9А = 108 W. Therefore, a stabilizer with a power of at least 108 W will be acceptable. However, it should be noted that the unit is selected with a 20 percent power reserve, otherwise it will quickly fail due to overload. Hence, the required power will be: 108×1.2 = 129.6W, i.e. for this case the choice of power supply for LED strip 12V – 150 W would be optimal.

In addition, it is possible to calculate the power of the converter using data on the main characteristics of flexible LED products. Having chosen the necessary type of tape, we find in the table the corresponding value of the power of one meter and multiply it by the total length of the backlight. Given the power reserve, we get the desired power supply.

Table of the main technical indicators of LED strips 12V:

| LED class | LED size, mm? | LED strip power, W / m | Tape density, pieces / m | The value of the light flux, lm / m |

| SMD 3528 | 3.5×2.8 | 2.4 | thirty | 150 |

| 4.8 | 60 | 300 | ||

| 9.6 | 120 | 600 | ||

| SMD 5050 | 5×5 | 7.2 | thirty | 360 |

| 14.4 | 60 | 720 |

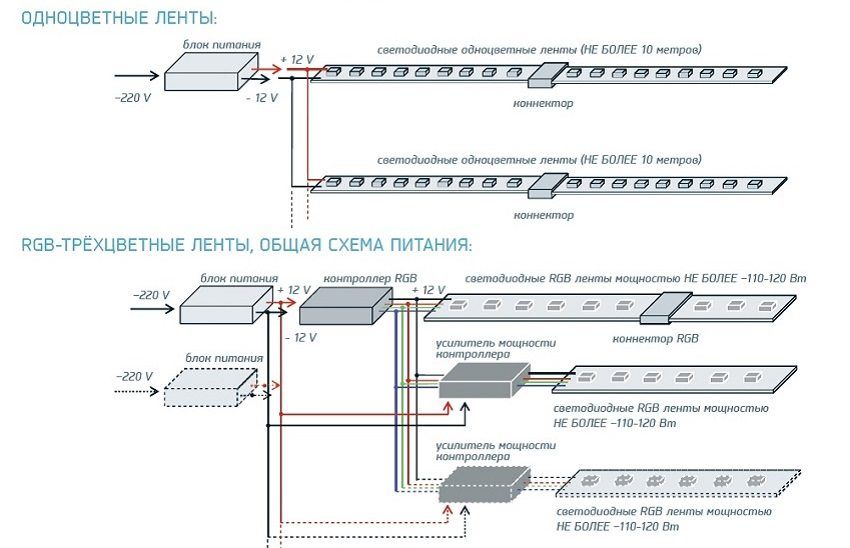

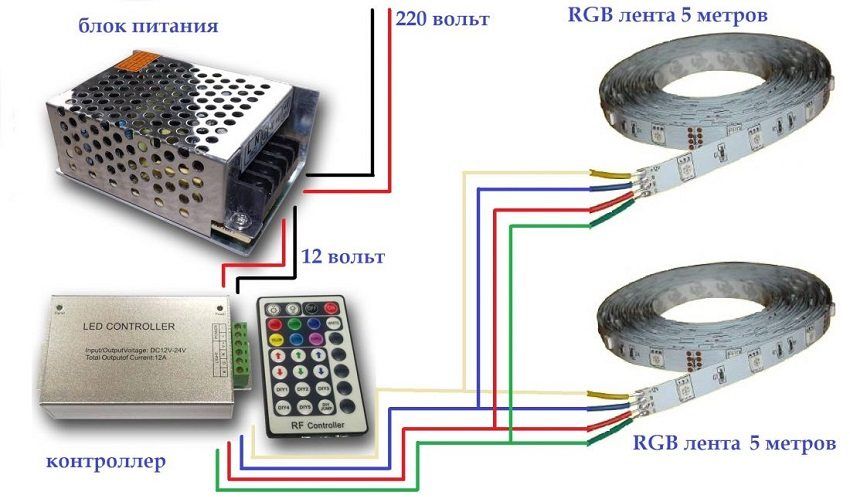

It is necessary to install the backlight to the selected surface after the power supply unit is connected to the LED strip. For example, we use the connection of the tape to a block, the casing of which is made of metal and has openings for cooling the components and the terminal strip. One of the walls of the case is equipped with a label indicating the marking for the correct connection of wires.

Terminals with the designation “L” and “N” – phase and zero, are designed to connect to the network 220V. Grounding is indicated by the characters “FG”. The terminals labeled “G” are interconnected and are designed to connect the negative terminal of the LED strip. Three terminals with “V” symbols are also connected inside the adapter and a corresponding positive terminal is connected to them. It should be noted that this marking is used on other models of converters.

To connect one-color ribbon, we connect the wires to the terminals, taking into account the polarity. The power cord plug has three wires with a brown, blue and yellow-green sheath. Brown and blue wires are attached to the terminals “phase” and “zero”, without fear of confusion, since they can be swapped. The yellow-green wire is connected strictly to the ground terminal. If grounding is absent, the terminal is not used: it does not matter for the functioning of the tape.

Note! The absence of a ground wire in the power cord is a violation of safety when performing electrical work.

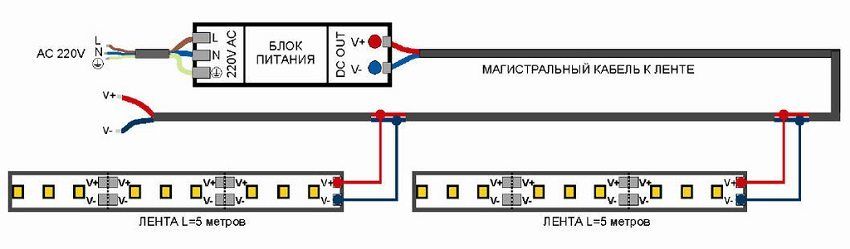

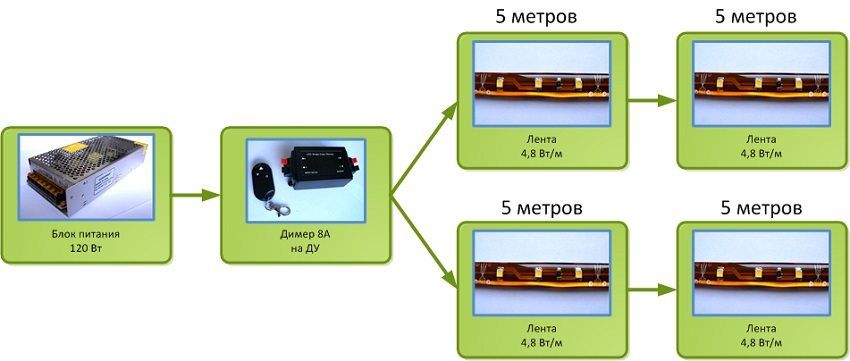

The above example of connecting a LED tape to a power supply unit is suitable for using the backlight from one tape up to 5 m long. If you need to connect several pieces of tape, you need to apply a parallel connection scheme.

If during interior design it is necessary to highlight several decorative elements located at a certain distance from each other, a parallel connection of the tape segments to the voltage converter is applied. This scheme is used in the case when the line of illumination of the structure is sufficiently long and exceeds 5 m.

Sequential connection of the segments will lead to uneven distribution of the load, as a result of which the LED strip will not work properly, emitting weak light in the final section. It is possible that the extreme length of the tape will not glow at all, whereas the initial one will begin to overheat and quickly fail. This suggests that you can not connect the end of the first segment to the beginning of the second.

When connected in parallel, each piece of LED strip must be independently connected to the power source. This can be done by connecting each piece of tape to the power supply with separate wires. But parallel connection can be done in another way: to lay the main wire line from the converter, to which you can later connect individual sections of the LED strip.

To make the contact of the conductors of the tape with the main wire reliable and sturdy, they use soldering or joining by means of special connectors. The use of connectors for connection greatly simplifies the repair of the backlight in the event that during operation there are problems. If the tape needs to be laid along a complex trajectory, the tape itself can be used as the main wire.

Price power supply for LED strip 12V

It is possible to buy a power supply unit for 12B LED tape not only at the points of sale of lighting equipment, but also on the web pages of manufacturers and organizations that sell LED products. There you can get acquainted with the range of models of converters, their technical characteristics and the cost of blocks.

By contacting the site managers you can get professional advice on how to choose the power supply for the LED strip, depending on its type and operating conditions. Experienced experts will help in choosing the right device that will ensure durable and high-quality operation of the LED design. As a rule, all products are certified and guaranteed by the manufacturer.

Note! When purchasing an open type converter, remember that it can be used only in rooms with a minimum degree of humidity and in places where the risk of water ingress is excluded.

Before you buy a power supply for LED strip, you should make an overview of the cost of products offered by different companies. This will help in choosing a model with the necessary parameters on favorable terms. Approximate prices of power supplies for LED strip 12V are presented in the table:

| Converter model | Dimensions, mm | Main settings | price, rub. |

| Interior Power Supply 12V 15W IP 20 | 70/39/30 | Supply voltage 110-220V, power 15W, equipped with a power indicator and voltage regulator | 270 |

| Power supply unit 12V 35W IP 20 | 85/58/32 | The supply voltage 110-220V, power 35W, has a power indicator and voltage regulator | 380 |

| Power supply unit 12V 60W IP 20 | 159/98/38 | The supply voltage 110-220V, power 60W, has a power indicator and voltage regulator | 540 |

| Power supply unit 12V 150W IP 20 | 200/89/40 | The supply voltage 110-220V, power 150W, is equipped with a power indicator and voltage regulator | 780 |

| Water-proof power supply unit 12V 30W IP 67 | 220/28/20 | Power supply 110-220V, power 30W, protection against moisture and dust | 560 |

| Water-proof power supply unit 12V 60W IP 67 | 148/40/30 | Power supply 110-220V, power 60W, protection against moisture and dust | 1100 |

| Water-proof power supply unit 12V 100W IP 67 | 202 / 71.2 / 45 | Power supply 110-220V, power 100W, protection against moisture and dust | 1670 |

Sometimes there are situations when it is necessary to make the highlight on a small area along the length. Then the purchase of the power supply will cost much more than the purchase of the tape itself. In this case, you can make the converter yourself.

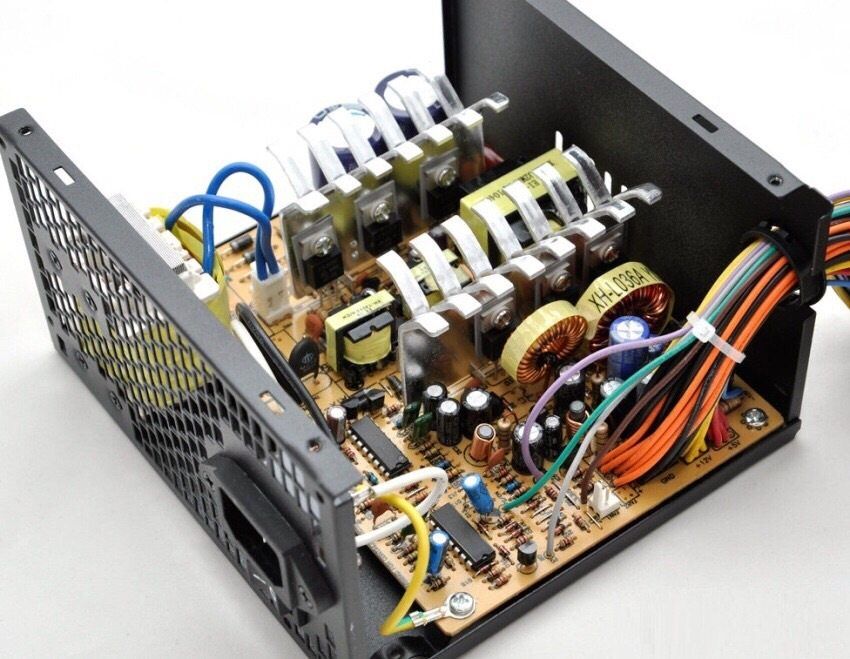

The cost of pulsed power supplies for high power LED strips very often exceeds the flexible tape itself. However, there is an option to reduce the cost of the backlight device, using as a stabilizer power supplies from outdated models of computers, TVs, tablets or other electrical appliances. Surely such products can be found in every home.

The power of 12V converters from old electronics usually ranges from 6 to 36W. This is quite enough for the operation of a small segment of LED lighting, for example, the kitchen apron area. You can use transformer models, but they are quite heavy and their power exceeds the same parameter of the tape twice. As a result, when such a power supply is connected to the tape, it becomes very hot, even if it is improved by adding additional cooling.

For normal operation of the LED strip, it is better to use pulsed power supplies, which, with sufficient power, weigh very little. For example, a 12V and 2A converter from a failed TV will work. The power of this device is 24W (12×2), which allows the LED strip to work properly, and the power supply does not overheat.

Helpful advice! Mobile phone chargers from 5V can be used as a power source for a small night lamp made from 3-6 LEDs assembled by hand.

You can adapt the electronic ballast (current limiter), which fed the fluorescent lamp, failed, under the power supply for the tape 12V. To do this, you need to convert a fluorescent lamp regulator into a step-down transformer, then, using a circuit, connect an LED strip to it. The conversion is a secondary winding, then a secondary diode and a capacitor are added to the circuit. The main condition is that the power of the tape must correspond to the same parameter of the ballast.

Sources of voltage 12V, failed, usually amenable to adjustment. If you have enough knowledge and skills, you can try to repair the voltage converter yourself. Faults can be fixed using the power supply circuit for a 12V or 24V LED strip, as they are identical.

The most common problems in the power supply are as follows:

- Capacitors C22, C23 fail — usually swelling or drying out;

- transistors do not function T10-11;

- faulty PWM controller TL494;

- dual diode D33, capacitors C30-33.

Faults in other components of the transducers are rare, but they are also worth checking out.

To diagnose and fix problems, you must perform the following steps:

- open the housing and check the fuse. If everything is all right with it, it is necessary to measure the voltage on the capacitors (C22, C23), having previously supplied power. The value should be around 310V. Consequently, the line filter and rectifier are normal;

- diagnose PWM (KA7500 chip) – if the 12 pin has a voltage of 12-30V, then we check the chip. Otherwise, check the power source of the duty voltage;

- the voltage at pin 14 after external power supply should be approximately + 5V. If not – you need to replace the chip. If you have, you need to check the chip with an oscilloscope.

Repair of the power supply consists in the replacement of faulty elements with the same components or their analogues. In order not to face the problem of breakage later, it is necessary to follow the recommendations of the manufacturer, since exceeding the permissible load limit will lead to failure of the adapter.

The right choice of power supply and related devices for LED systems ensures durability and quality of lighting. Thanks to these devices, LED sources emit bright flicker-free light that can gracefully transform your interior.