Products manufactured from polymers are becoming more widely used. Ribbed corrugation cable is used not so long ago, but it is the best option of all technological innovations to protect electrical networks. Easy, compact and flexible channels from PVC keep a form, forcing out outdated technologies. In the selection criteria and features of the installation of protective corrugations made of polymers should understand more.

What is polymer corrugated cable pipe

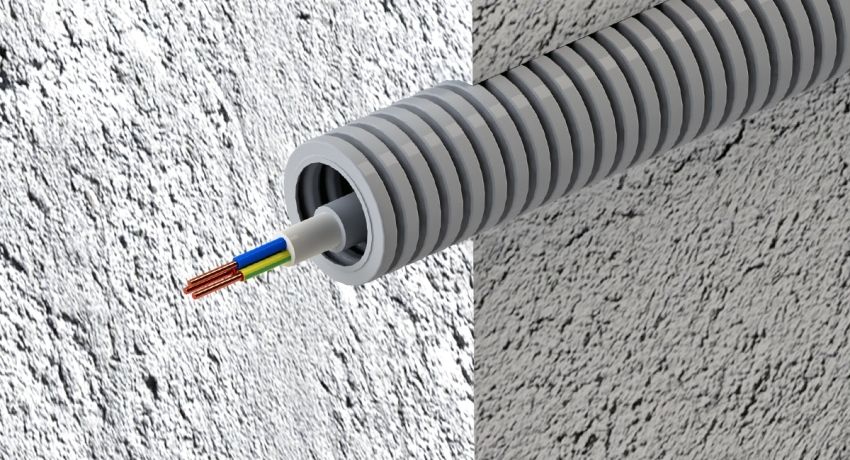

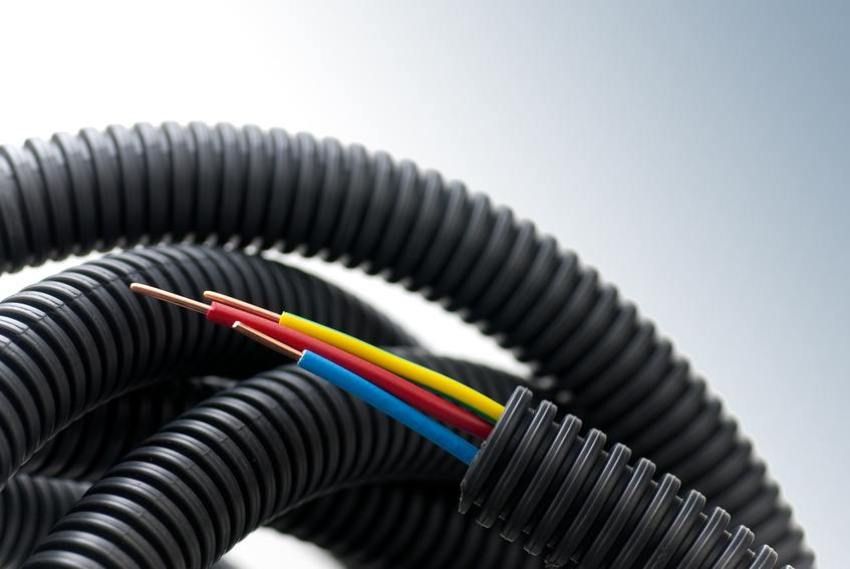

The corrugation for electrical wiring is a flexible PVC pipe. Due to its properties, including increased flexibility and elasticity, polymer products facilitate the installation of electrical networks in hard-to-reach and exposed places. For example, in houses built in earthquake-prone regions, with vibrations, it is easier to protect the wiring that is isolated in this way.

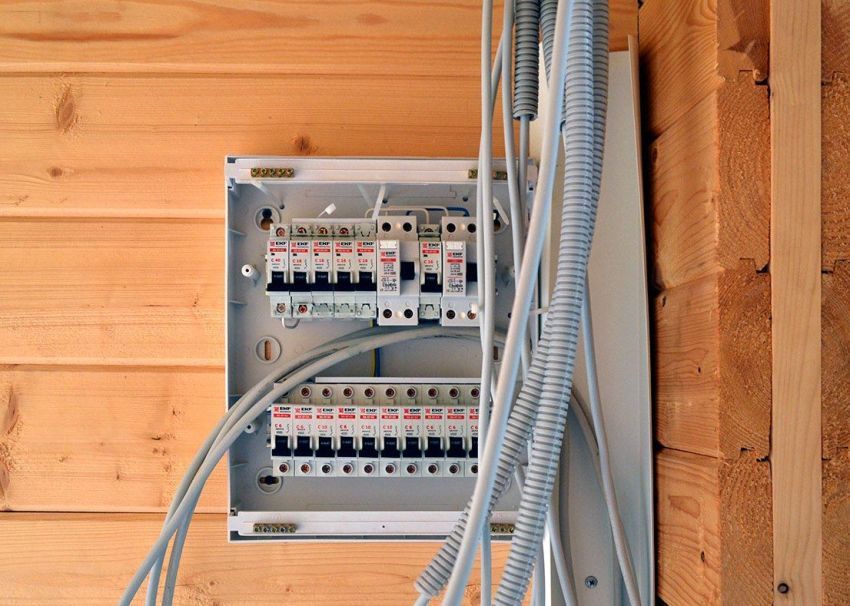

Protection in the form of PVC pipes – this is also the possibility of combining several wires in one channel. This method is used for the installation of complex multicomponent cabling, lighting design and suspended ceilings with combined lighting. Scope of corrugated pipes is quite wide. Modern enterprises produce several varieties of special-purpose products.

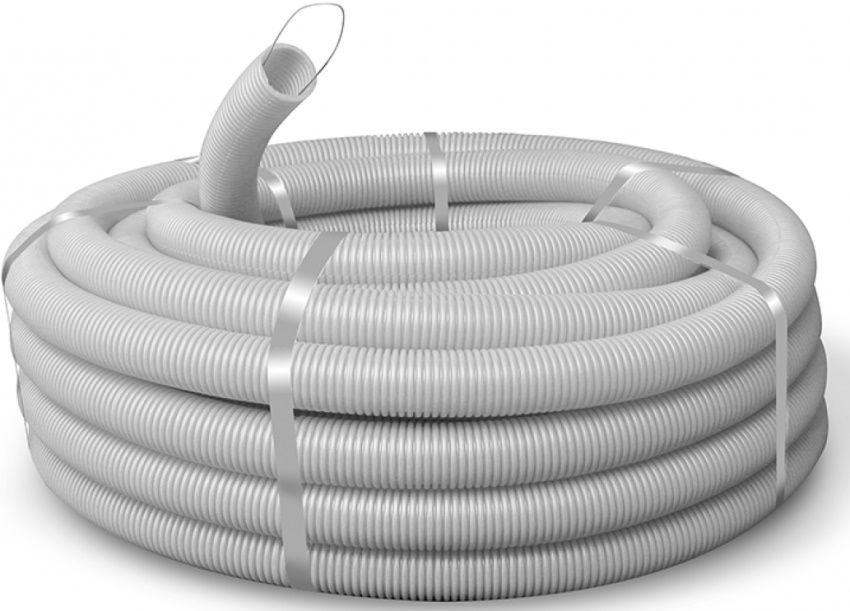

Corrugated PVC pipe for cable, as a rule, of small diameter, which eliminates the need to carve a deep and wide channel for concealed installation. It is produced in coils, in such packaging it is convenient to carry and transport.

Important! Low prices for PVC – this is an insignificant surcharge for the quality, reliability and speed of wiring during the construction of new and reconstruction of old facilities.

Polymeric materials from which the pipe for cable laying is produced have a lot of positive properties. For example, if a fire breaks out due to a short circuit, the rapidly decaying polymer prevents the spread of fire.

PVC pipe for electrical wiring is also an excellent insulation and safety, which is important not only in residential buildings, but also in production conditions. High voltage cable is much safer to lay in the repair, knowing that the polymer product protects against electric shock.

The corrugated structure is able to withstand tremendous pressure and mechanical stress, which no smooth pipe can demonstrate under the same conditions.

The ease of use of PVC corrugations for wiring is not in doubt. The advantage of an isolated installation is that it is easy to perform at any angle, even on the surface of the arches and arches.

In hard-to-reach places and on curvilinear sections, it is very difficult to make hidden highways in another way. It is the flexibility of the product that guarantees high-quality installation of the electrical cable with accurate repetition of complex bends with any architectural features.

A flexible corrugated pipe of a small section makes it possible to carry out the installation of complex joints and turns, up to a 360 ° turn. A cable embedded in a hidden groove fills it evenly, reducing the cost of plastering surfaces after the initial installation.

In modern construction, corrugated pipes are mounted not only inside buildings, but also outside them, which finds application in organizing the power supply network for objects with outdoor lighting, especially in a suburban household. For some time, the installation of electrical networks is rarely performed without the use of flexible insulation. In certain cases, landscape design is taken into account. For example, it is recommended to use a red corrugation for a cable that provides night illumination:

- paths and flower beds;

- pool or fountain;

- baths and saunas;

- artificial reservoir;

- BBQ and barbecue facilities;

- covered galleries or terraces.

Ease of use is an important argument for using corrugations for laying cables in the ground and during outdoor work. It is cut with scissors for metal or other suitable devices.

At the moment, a protective polymer sleeve is available for various construction needs, including sewer corrugation and protection for cables of different voltages. Depending on the properties of the polymer and the size of the corrugations for the cable, experts recommend using it for different types of wiring:

- for power cable;

- for low-current networks (telephones, television and computer UTP wire).

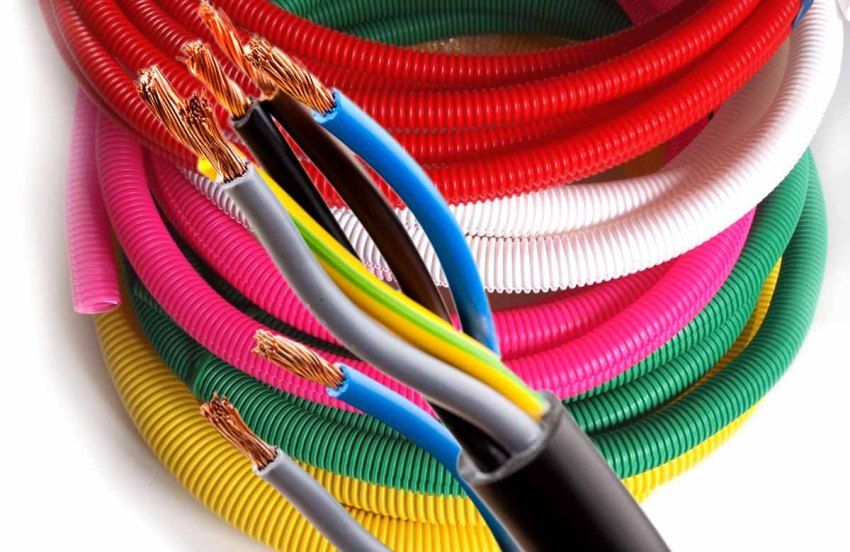

Protective corrugation, in accordance with the purpose, is available not only in the polymer, but also in the metal version. Flexible tubular products differ in material, color and design (for example, there is a double corrugation). Inside the product they pull a cable, often not even one – it all depends on the working conditions and the type of wiring:

- hidden inside;

- outdoor;

- underground.

Helpful advice! When buying, pay attention to the thickness and cross section of the corrugations, so as not to overpay for unclaimed properties. The cable should easily pass inside the sleeve.

There is another type of product classification – by degree of strength:

- light tubes;

- heavy;

- super heavy

Light corrugation is used for flush mounting inside the building (sensitive to ultraviolet). Heavy and dense corrugated products are produced for laying underground (they are characterized by increased resistance to pressure).

For the convenience of determining the destination, a conventional color designation is used, which is reflected in the table:

| No. p / p | Color corrugations | Scope of application |

| one. | Gray | Standard wiring |

| 2 | White | Computer networks, Internet |

| 3 | Green | Telephone or other low voltage cable |

| four. | Red | External power cable |

| five. | Blue | In the “warm floor” and flexible vodogonah |

| 6 | Yellow | Gas supply needs |

| 7 | Corrugated black and brown | Insulated wires for household appliances and other electrical appliances |

This is a common industrial and construction standard, but it is not always adhered to, especially if in the remainder after a large amount of work there is a small stock of the product in bays.

Before the advent of protective flexible PVC pipes for electrical systems, the cable was directly bricked into a recess in the wall. Installation was complicated by the fact that the open ends were screwed to a tire or other support, passed through a piece of metal pipe. In case of emergency or malfunction, the cable was removed from under the plaster (with the risk of damage).

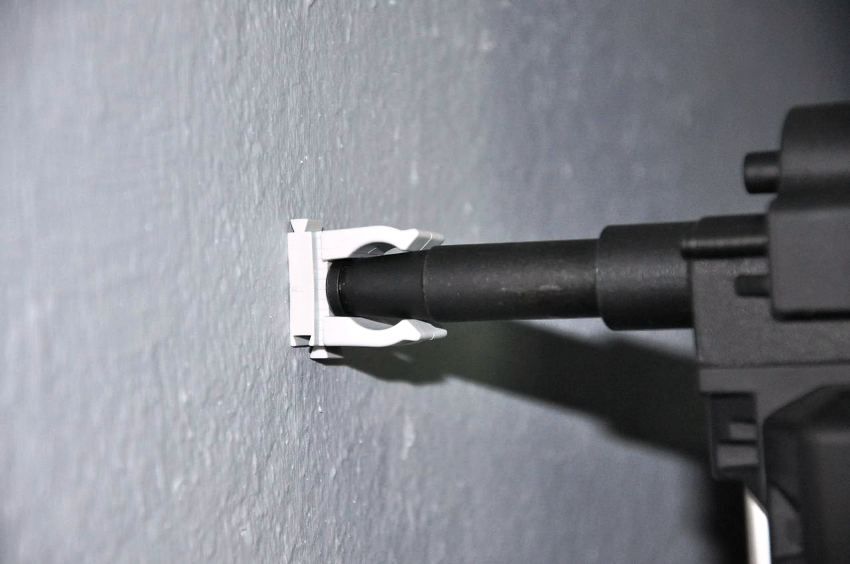

A careful study of the range of modern proposals in this field of application makes it obvious that a regular hollow corrugation and a product with an internal probe are being sold. He is often called the “broach” – and this is his appointment.

Helpful advice! Consider how to skip the wire inside the corrugations. The best option when installing the system is an opportunity to hook it and quickly stretch it.

The probe, if provided, is always visible inside the polymer tubes. This is a thick metal wire, located inside the entire length. The protective sheath for the wiring is cut with the probe as needed.

It is very simple to use the broach: hooking the wire to the end of the probe, pull the cable through the entire length of the polymer tube. The probe is a guarantee of the convenience of filling the tube with an electric cable. The simplest engineering solution confirms the saying that everything ingenious is simple. Only by pulling the cable inside the corrugations to a greater length, you can appreciate the simplicity and wisdom of this solution.

At small segments of corrugated tubes (for example, when there is a need for insulation of the wire connection), the probe is not used.

Attention! Doubtful savings are not justified by the acquisition without a probe inside the corrugations for the cable: the price differs insignificantly, and work without a probe is slowed down almost twice.

Ease of use of corrugations is also in the fact that cable protection is performed without special tools and does not require much effort. All that is needed is an internal probe and a cutting tool, after which the cable is placed in the prepared grooves (grooves).

When dismantling the old circuit wiring corrugated sleeve does not necessarily remove from the groove under the plaster. After removing the wires from the insulating cavity, the probe will no longer be required. A corrugation hidden in the strobe may remain in it, which will eliminate the need to make repairs. It is enough to extract the desired piece of electrical cable by pulling on its end. Empty corrugation is recommended to fill the edges with foam.

A variety of corrugations for cable diameters, differences in section and thickness allow it to be used for various purposes.

As you can see, before purchasing protective products for electrical wiring, it is worth considering all the characteristics and clarifying how to stretch the cable into the corrugation. When laying the cable inside the corrugations on a large segment, it is desirable to have a probe to simplify the broach. Extra heavy double corrugation is applicable only for underground cable installation and inside the floor with increased load. In the domestic environment is available self-installation of light products, if the cable section is less than the diameter of the corrugated sleeve.