Increasingly popular with the owners of two-storey cottages are the stairs to the second floor on a metal frame. Thanks to the achievements of modern technologies and the development of design solutions, such designs are able to combine various materials. In most cases, these are combinations of wood and metal. But more and more often in the configuration of stairs on a metal frame glass and tile, ceramic granite and stone get on together. The possibility of combining a variety of materials in such ladder designs is limitless. Ladders look creative and at the same time possess all the qualities necessary for safe ascent and descent along them.

Stairs to the second floor on a metal frame: the advantages of structures

The relevance of the stairs to the second floor on a metal frame is explained by high strength and the ability to combine a variety of materials. The construction on the metal frame is the second rated use in private homes and cottages after wooden stair systems.

The main advantages of the stairs on a metal frame include:

- relatively simple manufacturing process;

- reliability and functionality of the ladder system – properly designed ladders can withstand fairly heavy loads;

- durability of knots at splicing by welding of the bearing elements;

- the ability to apply different types of metal: pipes, reinforcing steel, channels, I-beams, angles and others;

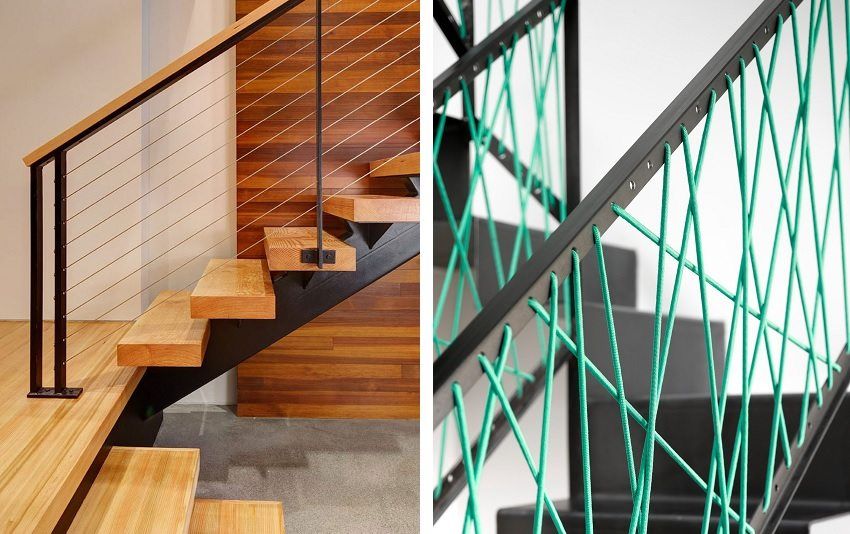

- the ability to combine materials and form a variety of designs of stairs;

- no squeaks during operation, durability of systems;

- the possibility of making simple designs of metal stairs to the second floor with their own hands.

A variety of forms and models convincingly shows the photo of the stairs on metal frames.

Independent production of a ladder on a metal frame is possible if the construction is simple and there are skills to work with the welding machine and metal.

Stairs to the second floor of metal (photos of various models are simply unique) can be straight and curved, spiral and elliptical. Depending on the coating, they are glossy, matte, gilded, etc. The variety of shapes and combinations of materials allow them to be used in various design styles.

According to the method of application, configuration and other various parameters, they are divided into types:

- Outdoor (auxiliary) – to such structures include stairs to the attic, fire escapes, ladders, stairs for basements, swimming pools, as well as systems of stairs that connect the two floors outside the house.

- Internal – the ladder designs established permanently indoors and connecting different levels of the room. Such stairs are by right the central element of the room decor.

According to the method of manufacture, there are welded and forged ladder systems. Independent production of metal stairs to the second floor in a private house using welding is a relatively easy way. The disadvantage of this method is that welding is considered a rough work, and the resulting product may not be quite aesthetic appearance. However, many craftsmen beat the place of welding, giving them decorative.

Forged stairs are made by forging metal. Not everyone can make such stairs. But even if the design has only forged railings for the stairs (the photo confirms this), this is quite enough to give it a unique elegant look.

On the device of a ladder from metal happen integral (fixed) and national teams. Integral structures are installed permanently from interconnected sections. Collapsible ladders have a set of inlaid parts and elements. Independent installation of such stairs is quite a feasible process.

According to the design of the metal frame of the stairs are classified:

- marching designs – consist of one or several marches. Depending on the location of the room, marches can be straight and turning. In turn, the stairs with a turn are with the connection of marches through the platform or with the use of turning (front, radius) steps. For self-production a more acceptable option is a ladder with a platform. Arranging a metal staircase to the second floor with a turn of 90 and 180 degrees is rather difficult. This will require accurate design and a clear calculation. However, such systems look spectacular and significantly save space;

- screw (spiral) stair systems. These stairs differ in that the steps are arranged in a circle, due to the fact that one end of the step is wider than the second. The supporting element is a pillar or column, around which the steps are mounted. Their advantage is that with the same length of the step, they occupy much less space, in comparison with the marching analogues. Making spiral staircases out of metal with their own hands (their drawings and diagrams are complicated) is a rather laborious process in technical terms, requiring the necessary knowledge and experience.

The supporting frame made of metal can be executed in several versions:

Oblique bearing frame. With this method of arranging the frame is a kind of support for the stairs. Such a system of stairs is durable and reliable. The number of support kosour depends on the project of the ladder and the expected load.

Helpful advice! If the length of the steps of the ladder is sufficiently large, the framework structures containing two cross-beams are used.

Tetivnaya support beam. In this design, the steps are inserted into special slots in the beam and their ends are not viewed from the side. Designs on bowstrings look more massive than models on kosourah.

Metal stairs on the bridge. Here the supporting element is the wall itself. Steps attached to it with metal fasteners. Such designs look as if suspended in the air, they are light and elegant. There are models based on the wall and on the kosour or bowstring.

To get acquainted with the types of designs on the Internet there are many photos of stairs to the second floor of metal.

For the purpose of safe movement, the design of the stairs on a metal frame are supplied with handrails and handrails.

Helpful advice! If the staircase has more than three steps, it must be completed with handrails or railings. It complies with the technical requirements for ladder operation.

Metal handrails for stairs can be of various shapes and colors. In this sense, manufacturers offer the widest range, allowing you to choose the elements for the stairs in the premises of any design. In addition to the safety function, they also carry an aesthetic component, giving completeness to the staircase ensemble.

Stainless steel handrails for ladders on a metal frame have gained wide popularity. Stainless steel railing is universal in operation, does not require special care. They need to be wiped from time to time with a cloth moistened with a special composition to impart shine. At the points of sale and on manufacturers’ websites there is a huge selection of components for stainless steel railings.

Handrails and railings for metal stairs (photos and prices are listed in the price lists) can be ordered of any type and form, according to individual preferences. The price of stainless steel products will be higher than on wooden or plastic handrails, but this will more than pay off with the reliability and durability of the steel railing.

Wrought iron railing for the stairs in the house (the photo illustrates this) are distinguished by sophistication and at the same time complexity in manufacturing. The process of making forged products – artistic forging. Any variations and styles of production of forged railings are possible from openwork to dense and massive. The disadvantage of forged fencing is their relatively high price.

For self-manufacturing metal railing using ferrous metal or steel. The main advantages of such railings are reliability and durability. If the products are properly processed, they are quite beautiful. To obtain the steel railing of the required form, a method of bending a metal, called cold, is used.

For the manufacture of iron railings used two types of welding: semi-automatic and argon arc. In the first embodiment, a lot of splashing is observed during operation. The second option eliminates this point and when argon-arc welding the docking seam is more even and neat, it lends itself well to stripping and polishing. Welded iron railings are susceptible to corrosion and require paint treatment.

The main advantage of ladders on a metal frame is the ability to combine different materials in a wide variety of combinations. At the same time, the ladders on the metal frame are strong, durable and can match any style of the interior.