Heat preservation is not only a component of economy. First of all, it is health and comfort. Excess moisture in combination with cold air leads to the formation of dampness and mold. To be in the room where the fungus appeared is not just uncomfortable, but also unsafe. In addition, this leads to the inevitable destruction of building structures that are constantly exposed to moisture. Modern reliable vapor barrier for the roof will help to avoid the above problems.

What is vapor barrier?

The level of dryness, comfort, heat preservation in the room depends largely on the condition of the roof. It is a barrier between the cold external environment and the internal heat of the building. The use of insulation in the absence of waterproofing for the roof is ineffective. Waterproofing prevents the penetration of steam from the dwelling into the insulating layers.

For a long time, conventional polyethylene film was used as a vapor barrier when roofing. But this material is mechanically vulnerable. In addition, it is characterized by a fairly high level of moisture permeability. Modern vapor barrier film for the roof has a vapor permeability of 0.4 g / m ?, and ordinary polyethylene – 13-20 g / m ?. It is used for all types of roofs: flat, pitched, when constructing the attic floor. Especially important is the reliable vapor barrier of the ceiling in a cold attic.

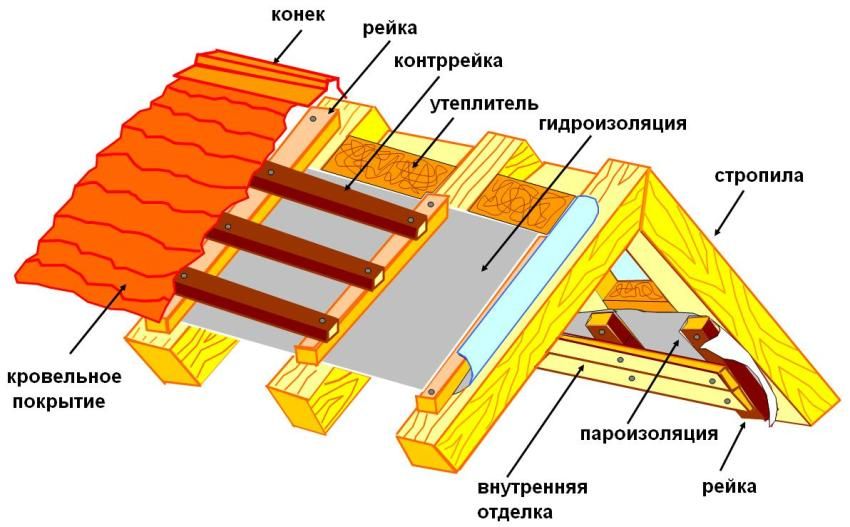

Parobaryer is one of the components of the “roofing pie”, which also includes waterproofing and insulation. If the “cake” is laid correctly and from quality materials, then the main functions of the vapor barrier can be considered:

- maintaining the microclimate, ensuring air exchange, maintaining the optimum temperature and humidity levels in the building;

- protection of the roof structure against moisture penetration from the outside and steam from inside, prevention of condensation, damage, fungus, mold;

- reduction of heat loss in the cold season, which contributes to saving costs for heat transfer fluids;

- increase of fire resistance of roof structures;

- reducing the cost of repairing the roof and building.

The lack of implementation of at least one of the above functions indicates a poor quality of the film or errors made during its installation.

Helpful advice! Before purchasing a vapor barrier material, it is necessary (in the absence of knowledge) to consult with an experienced roofer. Incorrect selection may cause steam to damage the insulation material.

Modern vapor barrier films, actively replacing simple polyethylene, roofing felt, glassine, have a wide range and purpose. The most common, affordable and mounting methods are the following types:

- standard vapor barrier film. It does not allow condensation to form on the roof and insulation;

- foil vapor barrier. In contrast to the standard layer, it has a reflective function and provides an increased vapor barrier, and also reflects and returns some of the heat to the room;

- membrane film. It has the effect of insulation and limited vapor permeability, which allows you to control the removal of excess moisture from the room.

Vapor barrier film can be made of polyethylene or polypropylene. Polyethylene is a fragile material, therefore a polyethylene product is reinforced with a special cloth or reinforcing mesh. Polypropylene films are woven material laminated on both sides with the finest polypropylene. This type of product is durable, resistant to UV light.

There are options when an antioxidant layer is applied to the polypropylene film, which absorbs and retains moisture, and after cessation of the steam supply, the layer dries out through ventilation. The device of vapor barrier of this type allows you to lay it only one way: a rough antioxidant layer is placed at the bottom, a smooth surface – at the top.

Films laminated on one side with a foil layer are distinguished by the highest vapor-permeability qualities and are the most suitable type of vapor barrier for rooms with high humidity (baths, saunas, swimming pools, etc.).

A special type of vapor protection are roofing membranes. It is a durable, temperature resistant material. It does not have low vapor permeability, but is effective in the construction of certain types of roofs. It is characterized by a more complex structure than ordinary film. The pores of the membrane resemble microscopic funnels. Due to this property, it does not allow steam to flow from the outside, but perfectly removes moisture from the inside. Currently, several types of underroof membranes are being produced:

- Perforated membrane. This is a reinforced film or a combined fabric with punctured holes. Used for arranging a cold sloping roof. It can not be used for vapor protection insulation. In frosty weather, steam can settle on the inner surface of the membrane.

- Porous membrane. It has many interfiber pores for the passage of water vapor between them. The vapor permeability of the material may be different, it depends on the size of the pores and the degree of hydrophilicity of their walls. It is not recommended to use this type of vapor protection in dusty conditions. In dry and windy weather, dust through the gaps can settle on the membrane and close the pores.

- Three-layer superdiffusion membranes. Made of several layers. They have no holes that can be penetrated by dust or moisture, which is a significant advantage. Membranes do not lose high vapor permeability in a dusty environment. Also worth noting is their excellent windproof ability.

- Two-layer film membranes. Cheaper version of the multilayer product. The absence of one of the protective layers significantly impairs reliability.

Steam insulation materials must be flexible, durable and easy to use. When fastening with dowels, screws, brackets, nails, it is necessary that they do not tear, but at the same time fit snugly to the mount.

Helpful advice! When choosing a vapor barrier material, special attention should be paid to quality, since this is the bottom layer of the roof construction and its repair is almost impossible.

When arranging the roof, it is important not only to know how to properly install a vapor barrier, but also how to determine the right material. Take into account when choosing, first of all, the type of roofing material.

If you plan to produce roofing from low thermal conductivity materials: slate, tile, ondulin, and onduvilla, diffusion vapor barrier membranes should be used.

It is recommended to protect the roofs of metal tiles, corrugated sheets and with a folded roof (joining sheets with a seam) using a vapor-proof film with an anti-condensate layer.

When choosing vapor barrier materials, the following parameters should be considered:

- vapor permeability;

- durability of functioning;

- installation features;

- the cost.

Is vapor permeability measured in g / m? per day. The lower the permeability, the more reliable the insulation, decoration, and structural elements of the roof are protected from wetting. To a certain extent, the film must provide air exchange, otherwise a greenhouse effect will be created for the room. Anti-condensate polypropylene films and breathable diffusion membranes provide optimal vapor protection.

The durability of vapor barrier materials due to a number of qualities:

- tensile and tensile strength;

- resistant to high temperatures;

- non susceptibility to ultraviolet radiation.

Low-cost plastic film can break already during installation and be destroyed by temperature changes. The vapor barrier membranes of non-woven man-made fibers with a protective layer are durable. They are resistant to mechanical damage and heat.

Features of installation must be known before purchasing the film, as the correct amount can be calculated only if you know the amount of overlap. Also, the purchase of related materials directly depends on the method of installation. If the adhesion of the vapor barrier material to the installation tape is low, then this will inevitably lead to a breach of the tightness of the vapor barrier layer. Therefore, you need to purchase a different type of adhesive tape.

The price of a vapor barrier for a roof directly depends on its quality. Budget options are short-lived. You must be able to correctly calculate the cost of the material. A low price per roll may not mean the optimal cost, but may be the result of a small amount. Only comparing the price for 1 m? Various types of vapor barrier will help to make the right choice.

Helpful advice! The quality of the film must match the quality of the roofing material. If the material is designed for long-term operation, and the vapor barrier is shorter, the entire “roofing pie” will have to be disassembled when replaced.

Vapor barrier is of two types: roll and sheet.

Installation of roll installation is as follows:

- the material is rolled out;

- measure the desired length of the canvases and place them with a lining (100-200 mm) on the adjacent fragments;

- fixed with staples or wooden slats;

- the joints and overlaps are fixed with adhesive tape for vapor barrier (or other adhesive tape).

Sheet installation requires the prior creation of wooden crates or frame from the profile, which will be placed waterproofing. You can fix the screws or a stapler (according to the material).

When laying the “roofing pie” the question: “Which side should put the vapor barrier on?” – appears among the first. The film, which is the same on both sides, does not cause any difficulties during installation: whichever side the vapor barrier is put on – the effect will be the same. The film has a two-layer structure, where one side is smooth and the second is rough (to hold condensate), placed smooth side out (adjacent to the insulation), and rough – inside the room.

To carry out a reasonable and rational choice of materials, to correctly make the installation of a vapor barrier – the desire of every homeowner. The content of the article is intended to help install the vapor barrier on your own. But even if such a decision is unacceptable, it is necessary to be aware in order to properly assess their costs and the quality of the work of the hired specialists.