The metal tile is along with a professional flooring the most demanded roofing material at low-rise private construction. Its consumer properties promote wide use. This is also prompted by the fact that the technology of roofing of metal tiles is quite simple.

Metal roofing roofs: photo options

If you look around you can see that the vast majority of private houses and economic structures are covered with metal tiles. Its profile and colors have so many options that everyone can choose a unique configuration among the surrounding buildings. Convenience of installation allows to apply these sheets on roofs of various complexity. The roofs of houses made of metal: photos, descriptions and installation features of the most unimaginable shapes and sizes can be found in the public domain. Many of them can push on ideas for the construction of its roof.

The owners who do not bother themselves with excessive delights can build an ordinary double-slope roof. Those who want to get additional space due to the attic floor are free to create a broken roof. Anyone who aspires to the unusual and pretentious, can build on the roof of the tower and other small architectural forms. And all of these metal roofs. Photos of various options are simply impossible to fully embrace.

When the choice is made and it is time to start building the roof, it is necessary to study in detail the technology of roofing of metal tiles. This is the only way to create a high-quality and durable object. After all, non-compliance with certain rules and recommendations can lead to adverse consequences.

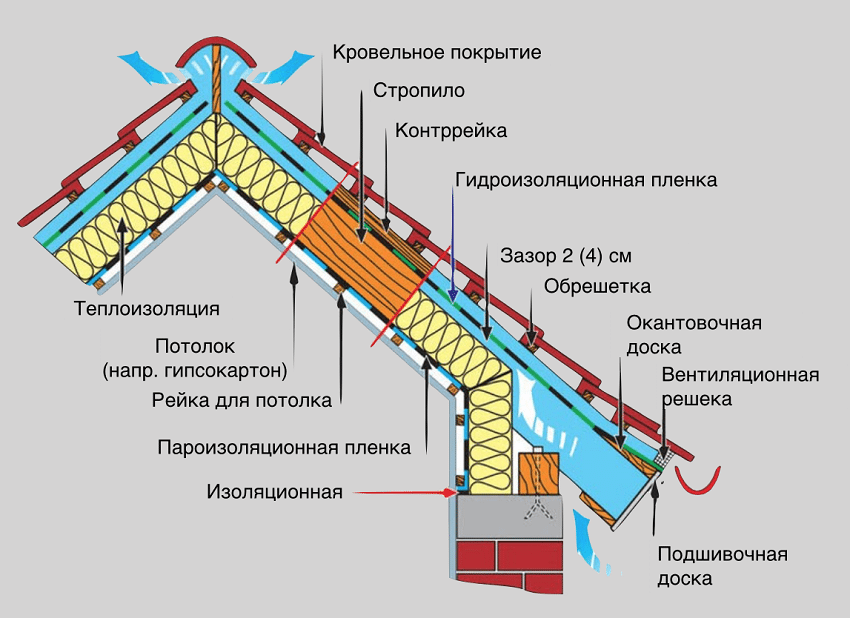

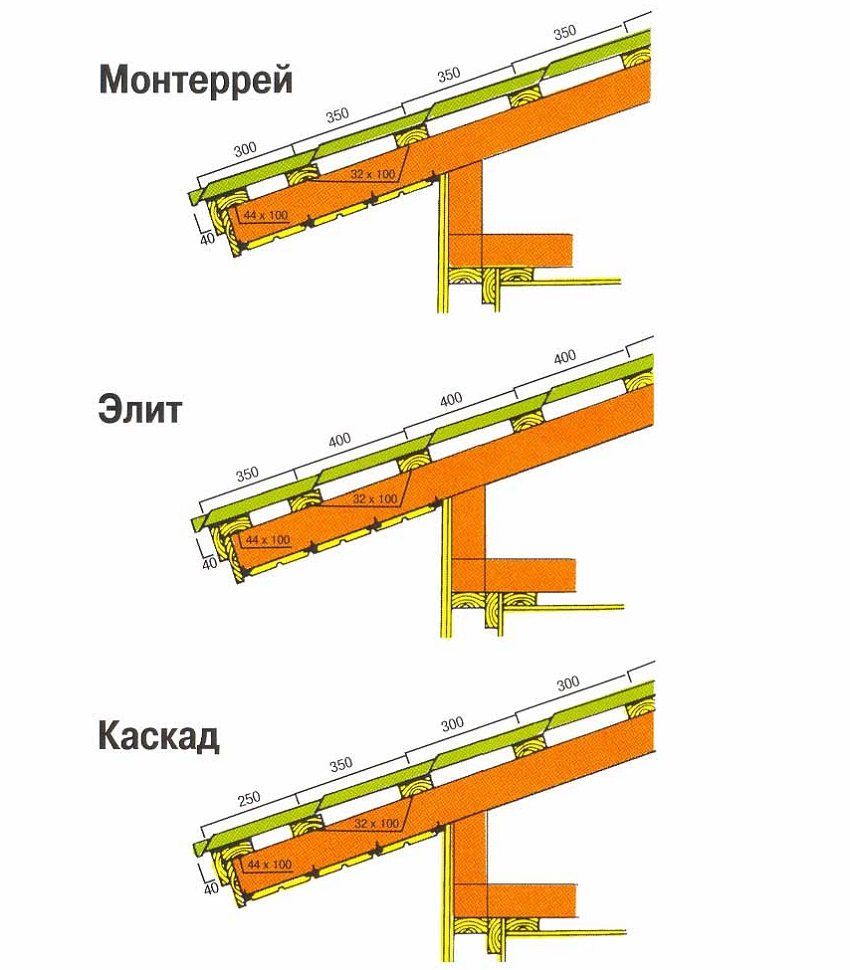

Any roofing device begins with the installation of crates. For each roofing material has its own rules. Since the metal tile comes with a different profile, the crate is made different. There are two types of crates: solid and sparse. In solid board fit tightly to each other, forming a flat surface. Any metal tile can be laid on it without restrictions. With a sparse crate things are different. To save material, boards on it are nailed through some distance parallel to each other. What this distance depends on the type of metal tile, or rather on the size of the profile wave.

Helpful advice! Experienced builders always recommend waterproofing when installing the batten. It will not allow condensate to accumulate under the metal tile, damaging the rafter system with time.

The technology of roofing of metal tiles involves the calculation of the parameters of the batten. The quality of all works carried out in the future depends on how correctly it is made. First determine what step will have the crate. To do this, measure the wavelength of the profile on the metal tile. The strongest place on the sheets is the bottom of each wave. It is with these points that the metal tile should rest on the batten boards.

Knowing the wavelength of the profile, it is easy to determine the pitch of the batten. After all, they are equal. However, before nailing boards with a calculated step, it is necessary to fill the ridge board and the first one from the eaves. They must be cut. And the first board is thicker than the next. If boards for a batten are prepared with a thickness of 25 mm and a width of 100 mm, then this board must be at least 40 mm in thickness, and its width may also be 100 mm. This is done so that the corrugated sheet rests against the edge of its first step on the resulting ledge in order to avoid rolling down. Next to the first and ridged one should be nailed along another regular board. Only after this is mounted the rest of the crate with the necessary step. After the end of the construction of the entire crates, you need to remember to nail the attachments for the drainage system to the first board.

Helpful advice! For the device of the sheathing, it is necessary to use a dry material of the same thickness. The use of undried boards can lead to their deformation.

Before starting the main works, it is necessary to prepare the tool. For work you will need:

- fairly long narrow rake;

- ordinary hammer;

- jigsaw, hacksaw for metal, scissors for cutting metal sheets;

- cordless screwdriver;

- roulette;

- punching machine.

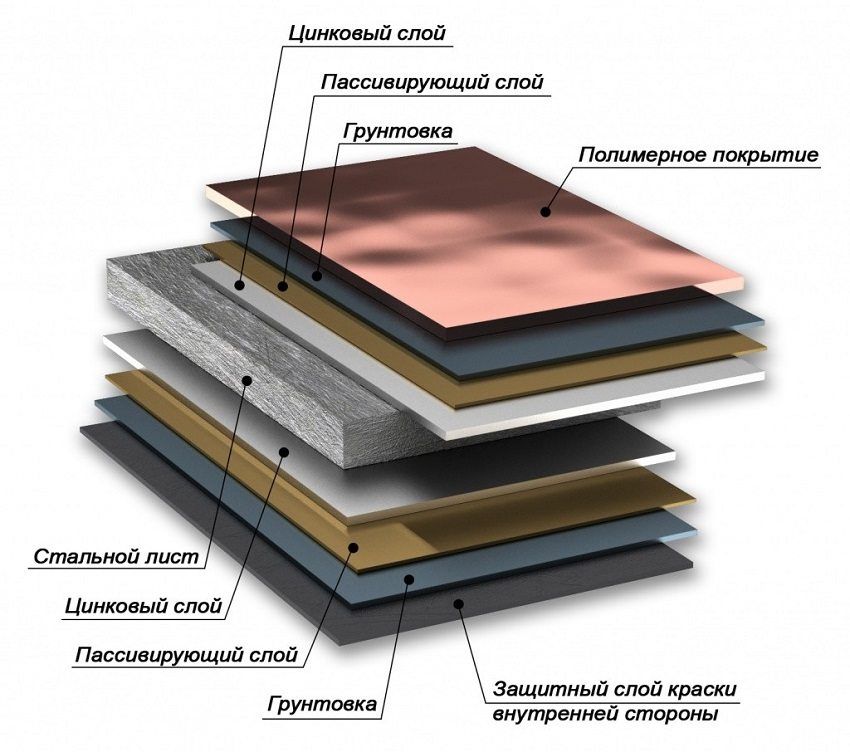

Contrary to the prevailing ideas, the Bulgarian is not needed. In no case can not use the abrasive wheel for cutting metal. This can lead to heat and destruction of the protective polymer coating.

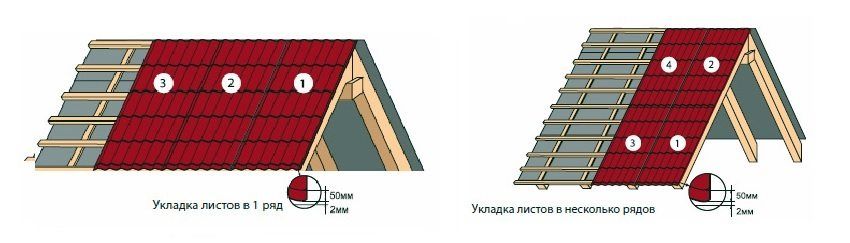

According to the technology of roofing, made of metal, the first sheet should be aligned along the bottom, but not along the end of the batten. It is necessary to ensure that the sheet lies strictly vertically, and its lower cut is parallel to the eaves and stepped below the edge by 40 mm. At the bottom and near the ridge it is attached using two screws. They are screwed with a screwdriver into the bottom of the gutter, and not at the top of the wave. Since the screws have rubber pads, the flow is not scary. They need to be screwed in without effort, so as not to damage the gaskets.

After the first sheet is temporarily fixed, the next one is overlapped on it. This should be done in such a way that all the stamped steps of the profile perfectly coincide with each other. The second sheet is attached only to the first, but not to the crate. In the same way, attach another 2 – 3 sheets. Then, if necessary, turn out one of the screws on the first sheet and align the entire structure more precisely along the eaves. Only after this fix all the sheets with screws to the crate. The rate of their consumption without fixing the additional elements is 7 pieces per 1 m ?, and the length is 28 or 35 mm.

Helpful advice! Before screwing in the screw you need to be sure that you will not get into the gap between the battens. If this happened, then you do not need to unscrew the screw. Thanks to the rubber gasket, the water through the hole will not leak.

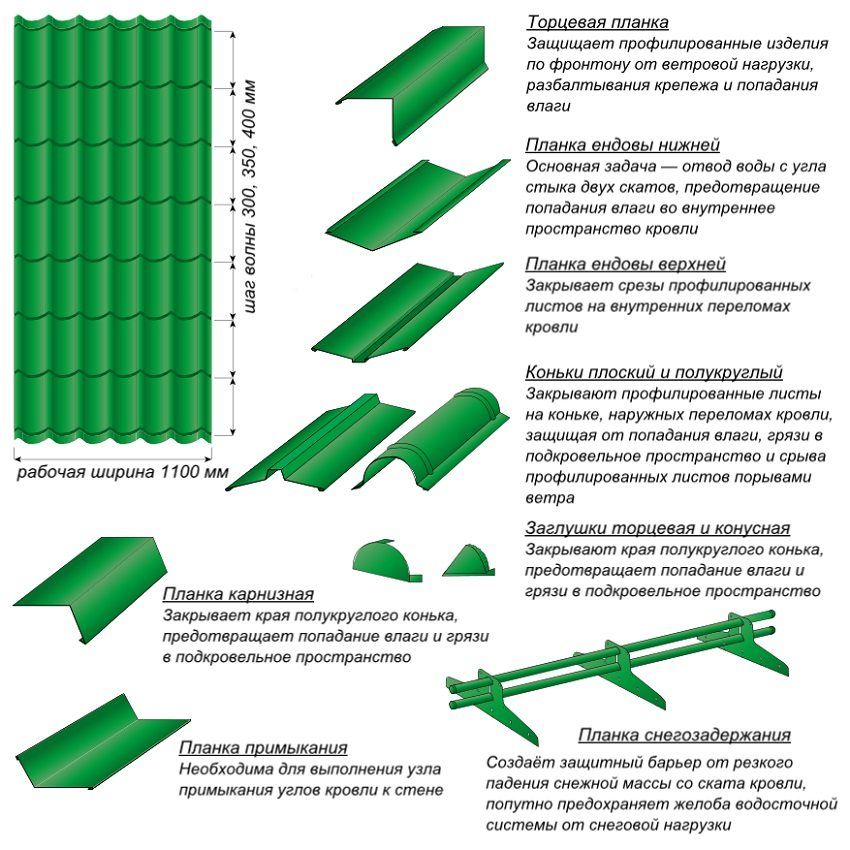

After the entire stingray plane is closed, it may be necessary to cut the last leaf along the stream. This should be done carefully using cooked tools. The final stage in the technology of roofing of metal is the installation of additional elements: wind and ridge, endy. They are purchased together with the main material and have the same color. Fasten them, too, with the help of screws, but of greater length (51 mm). It is necessary to pay attention to the fact that the ridge is parallel to the eaves and the level of the horizon.

Separately, it should be said about the arrangement of connections. This term refers to those places where the roofing material is in contact with pipes, facade elements or dormer windows. They are the most risky places for the penetration of water, so to achieve tightness here is the task of any builder. This can be done with the help of special aprons from the same material as the metal tile itself. Under it, a seal is put and everything is coated with sealant.

A beautiful and durable metal roof is obtained only with proper and accurate installation of all elements of the roof.