The ebb for the basement of the foundation is mounted on the upper, protruding beyond the wall plane, part of the base of the house. This protrusion is formed due to the fact that the walls are usually thinner than the base, as the latter, together with the foundation, carries the main load. Water flowing from the walls, falls on this ledge and accumulates there. Penetrating into the pores of the concrete base, it freezes with the onset of frost and gradually destroys the monolith. To prevent this from happening, the foundation must be protected from moisture. This is done by closing the protrusion with a waterproof inclined strip.

What are the ebb for the basement of the foundation

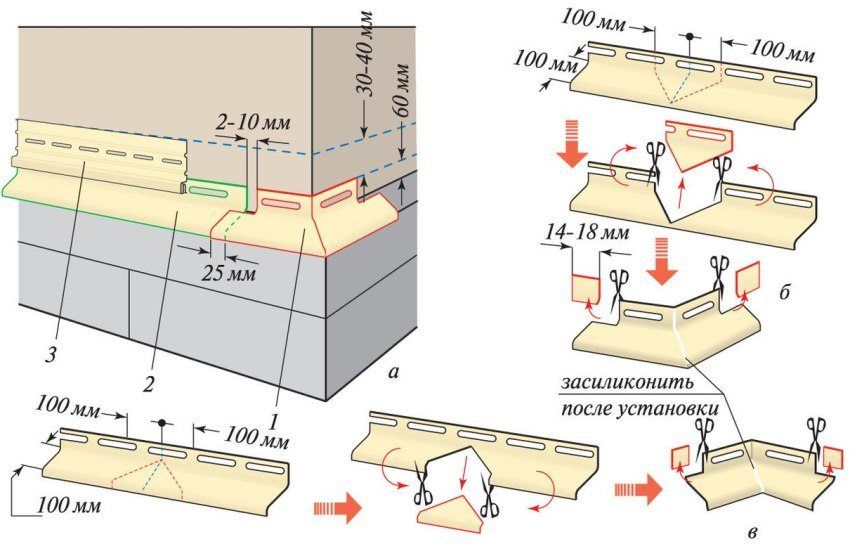

These devices always have the form of strips, similar to the shelf, whose width varies from 50 to 400 mm. The bar is installed along the perimeter of the entire base on its protruding part with a small 5 – 10 degree slope in the direction opposite to the wall. This allows water to flow freely away from home, without getting on the foundation. Ebbs for the basement base can be made independently of any waterproof materials, and you can buy at a hardware store. The industry produces several types of them:

- plastic drips;

- galvanized steel strips, including painted and coated;

- aluminum and copper;

- concrete products;

- clinker base ebb.

In order to choose the right material you need, you should familiarize yourself with the properties of each in more detail.

When building ventilated facades lined with vinyl siding, you can stop your gaze on plastic base tides. They are best for the texture match the material used. Even the color can be matched perfectly with the general background. PVC sills are prepared and on order, so you can get any desired size and shape.

The long-term potential of the operating time, as well as good resistance to environmental influences, both climatic and mechanical, makes this material in demand in the construction industry. Plastic has a completely waterproof structure and moderate cost.

Helpful advice! When purchasing plastic ebb, it should be kept in mind that the fragility of low-cost models and the inability to make subsequent repairs. Damage will have to replace the entire bar. Therefore, it is worth choosing thicker and more durable products.

In this segment of products there is a very large range of species. The cheapest ebb for the basement plinth is made of galvanized steel, and the most expensive ones have a polymer coating. Some options may have an exclusive look. At the same time, even in the manufacture of the simplest metal sheen, great importance is given to the aesthetic side. After all, this shelf is mounted on the facade of the building and should emphasize the line, creating the effect of completeness of the whole picture.

The technology of effective insulation of the basement penoplex. Comprehensive insulation of the foundation of the building with the use of foam panels. Three main methods of basement insulation.

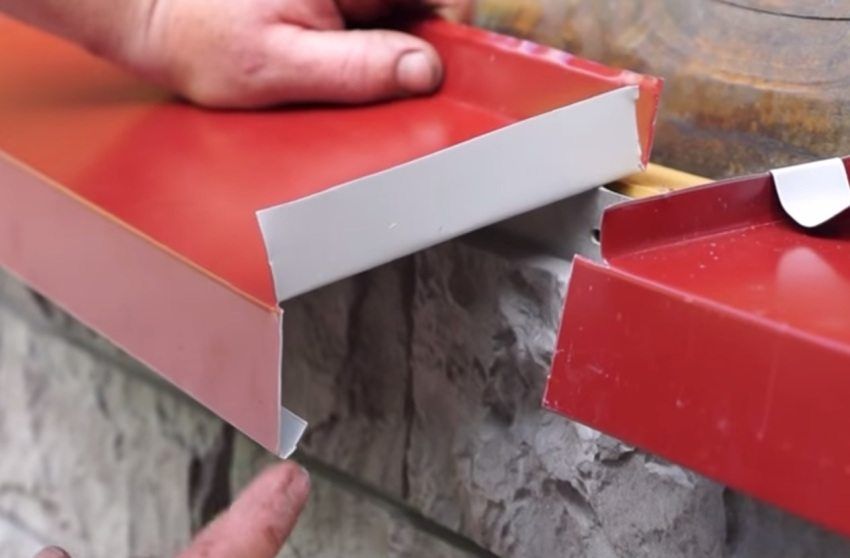

Outwardly, all metallic ebbs constitute a shelf with bends on the edges. One limb is made up, for fastening the part to the wall of the building or the frame of the ventilated facade. The second is directed downwards and turned inward. This design does not allow water, as a result of the capillarity phenomenon, to return to the surface of the foundation. The length of the slats most often is 2 m, and the width is from 5 to 30 cm, with a steel sheet thickness of 0.5 – 1 cm. The colors may be completely absent or be absolutely any of the ones offered by one manufacturer or another. The cost of such ebbs per liter starts from 1.e. and can achieve for some models 10 cu

The main advantage of metal slats for castings is their aesthetic appearance, ease of installation and resistance to shock. Aluminum sills that are much lighter and more durable than steel ones are especially appreciated. Electroplating does not allow the metal to collapse for decades. Copper otliva for the basement of the foundation today have somewhat lost their former popularity due to a fairly decent cost and the need for constant thorough care of them.

Installation of the slats on the basement is carried out by mounting them with screws or dowels directly to the walls of the building in the place of the upper limb, or on the guides of the ventilated facade. This process is not complicated and is performed by conventional hand tools.

Helpful advice! When installing the socle ebbs it is necessary to lay the slats one after the other with an overlap of at least 3 cm. It is not necessary to trim the extreme slat. It is better to block it from the previous one. Cutting metal will damage the protective layer, which sooner or later will lead to corrosion and destruction of the part.

For monumental buildings, finished with brick or natural stone, it is preferable to use concrete castings for the foundation base. They have a solid appearance and are guaranteed to protect the foundation of the house from any negative impact from outside. For the manufacture of such castings used cement M450. It is frost resistant and very high quality. Add river sand and granite rubble to the solution. For better ductility and water resistance, plasticizers are used. The solution is poured into silicone molds, which may have different geometrical parameters. At the same time the surface of finished products turns out very smooth and equal.

The length of the standard forms is 3.9 or 6 m, and the width is made according to the size of the base. The color scheme is quite extensive from manufacturers, but you can order an individual shade. Concrete ebb have excellent decorative properties, but their installation must be provided in advance by the project, as they are very massive. Fix such ebb with a special solution.

Helpful advice! Existing basement outflow of concrete can be painted with any facade paint. This allows you to create a variety of design of the facade of the building.

Often houses are finished with expensive and aesthetic material – clinker tiles. This material perfectly protects the building from any influences from the external environment. It is logical to propose to protect the foundation of these buildings with ebb of the same material. They are produced by the construction industry, and they can be purchased in the same place as the clinker tile. It is necessary to plan foundation arrangement by such type of otliv even at design. Installation of clinkers requires professionalism and attention.

Despite this, many people choose this type of building facade design. After all, the house sheathed with such material has a fundamental and solid appearance. He clearly emphasizes the social status of its owner.

Installation of low water in its place is made before you do the facing of the facade. Material casting choose, such that it is combined with the finishing material of the facade of the building. For a siding make plastic outflow, under a brick and a stone arrange concrete or brick castings. Peaks from metal are universal, and will be suitable for any kind of material of finishing. Since most often in mass individual construction, metallic types of castings are used to protect the foundation of the house, we will consider in more detail the features of their installation.

On the so-called grillage, a horizontal surface of the basement is laid several slats along the entire wall. After alignment, they are fastened together with the smallest screws. If the walls of the house are lined with brick or made of lightweight concrete blocks, then pre-make holes for fixing the ebb with wooden or plastic plugs. Ebb screws attached to them. If the walls of wood or ebb need to attach to the frame of the facade, then you need to fasten immediately to the screws. Joints between the slats can be treated with sealant to prevent liquid from entering through them.

Helpful advice! For decorative design ebb at the corners of the building, use special corners. They have a presentable appearance and are sold together with the slats of the same color and width.

The use of castings for the basement of the foundation will significantly increase its service life. In addition, the correct choice of the type of ebb and their high-quality installation greatly improves the appearance of the building, giving it integrity and completeness.