High-quality insulation of the house – the key to a comfortable life in the cold season. Therefore, in order not to disturb the frosts in winter, you should think about the choice of material and technology of insulation. This applies to all cases, including insulation of a wooden house outside. Consider what you should pay attention to when choosing the right material, as well as how to do everything you need yourself, if we are talking about a building made of wood.

Warming of a wooden house outside: the most common materials

There are a lot of thermal insulation materials. Some of them are very popular among consumers, and some, on the contrary, are used quite rarely. Consider what characteristics determine popularity, and what options are used most often:

- Stone wool in slabs is a light and comfortable material that is transported without any problems and can be cut even with a regular knife. These plates are placed between the elements of the frame, and then covered with a vapor barrier and waterproofing material from different sides. The main thing – in the process of transporting the mats, do not compress or tamp them, as they are easily deformed;

- Ecowool – a material created on the basis of cellulose, which is pressed and packed. For insulation with its help, you can use two options. In the first case, I take out the cotton from the open packaging, and, slightly kneading it, tamp the walls. Definitely say how good this method is difficult. Some manufacturers claim that with such insulation you will not know the problems from 10 to 20 years. Although it is impossible to deny the possibility of shrinkage and deterioration of the thermal insulation properties of the material. The second method is called wet, since ecowool is sprayed onto the walls, due to which material sets to the frame and the risk of settling is eliminated;

- Polyfoam is a very common and cheap way to insulate a building. Its low cost is due to fragility, fragility, as well as the need to additionally cover it with a moisture-proof membrane in order to further avoid the accumulation of condensate. It is important that for insulation you need to buy only non-pressed sheets of foam;

- polyurethane foam – a material consisting of two separate components, mixed together under high pressure. In contact with air, it behaves in the same way as regular foam – it expands. Warming a wooden house with polyurethane foam is quite effective and reduces heat loss to a minimum. In addition, PUF tends to repel water;

- Insulants of natural origin are various mixtures and plates made on the basis of sawdust, straw, clay, etc. The cost of this method is low, but choosing this option, you must be ready to tinker. For easy-to-use natural insulation can be attributed, perhaps, flax fibers.

In addition to traditional materials, there are several options that, although they have not yet acquired such popularity, still often surpass the characteristics already considered.

- Basalt slabs for facade insulation. Price is the only flaw that can be found in this material. Despite the similarity with mineral wool, this material is several times superior to it in technical indicators and characteristics. It provides excellent thermal insulation and is able to withstand heavy loads and temperature drops. Over time, it does not shrink and does not lose its characteristics. So its considerable, in comparison with other materials, the cost can be called more than justified.

- Penoplex – a material that is rapidly gaining popularity, despite the fact that it has appeared on the market recently. The material is an extruded polystyrene foam, characterized by low weight and good moisture resistance. This allows you to use it without laying additional waterproofing layers.

- Insulation “Arctic” consists of synthetic fibers that are bonded to each other under the influence of hot air. The material is great for use in the harshest weather conditions. This insulation is breathable and provides good thermoregulation in both winter and summer.

Helpful advice! When working with any kind of thermal insulation material, it is necessary to use personal protective equipment to prevent fibers from entering the respiratory tract and on the skin, as this may cause irritation.

Choosing the right way to work on the weatherization of a wooden house is a guarantee of a quality result. Internal warming of houses is used extremely rarely, since a thick layer of material will noticeably reduce the area of the room. In addition, the insulation of walls in a wooden house from the inside will lead to the fact that the outer side of the walls will still be exposed to cold, which will lead to freezing of wood.

Improper work and failure to comply with the technology of warming a frame house can lead to the fact that the tree starts to rot from the inside and becomes a favorable environment for the life of fungi and mold. That is why the method is no less important than the choice of a suitable material for this purpose.

But with outdoor warming it is also important to ensure that couples can freely go out. Otherwise, the wood will deteriorate and control the condition of the walls will be impossible.

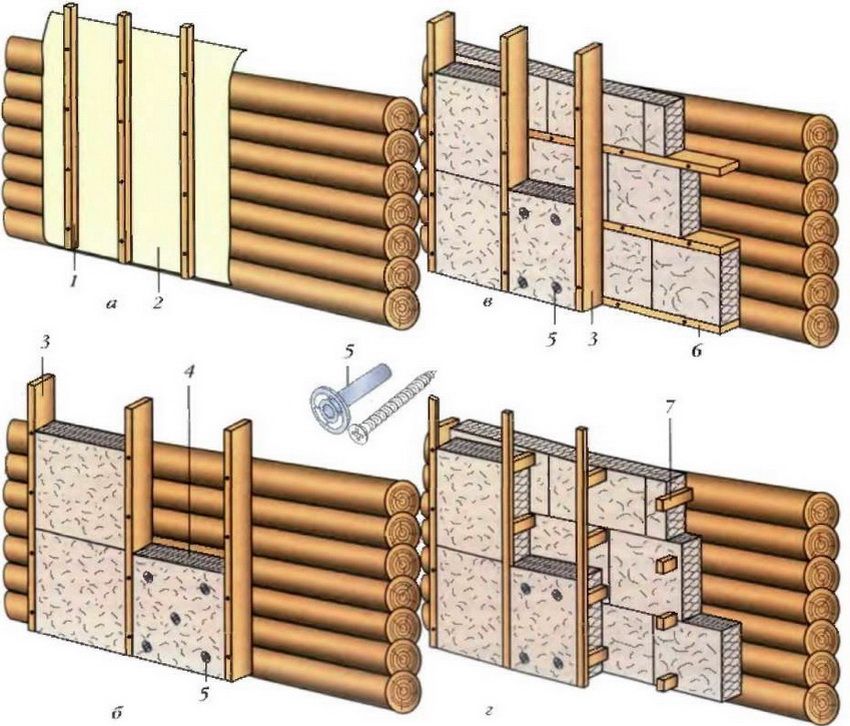

When laying the insulation layer, it is necessary to ensure waterproofing of the walls. Pergamin is excellent for this purpose. Despite its low cost, it does an excellent job. Initially, it is necessary to cut strips from it and fix them on the frame with a stapler. The pitch should not exceed 12 cm.

Sheets of glassine are glued overlapping in such a way that the overlap is about 10 cm. This helps prevent condensate from entering the thermal insulation material.

Helpful advice! If the house is planned to be covered with siding after weatherization, then care should be taken to ensure that there is free space between it and the insulation (approximately 30-50 cm). This will not allow moisture to linger in the frame.

When the glassine is fixed, you can proceed to laying insulation. Minvat in this case is a great option, as it is not prone to fire and is easy to install. The main thing is to correctly choose the thickness of mineral wool for wall insulation. For a temperate climate, this figure should be 80-100 mm, and for regions with severe winters, you can use a material 150 mm thick.

The technology of thermal insulation of facades with mineral wool provides the following sequence of work:

- it is necessary to measure the distance between the racks;

- add 5 cm to stock from each side to the result;

- using a sharp knife, cut the mineral plates for wall insulation to the desired size and lay them on the wall over the waterproofing;

- The joints between the frame and the insulation are additionally closed with cut strips 3-4 cm wide.

From above, a layer of vapor barrier material is laid. Penophenol is excellent, which is attached to the frame with a construction stapler. After that, it remains only to sheathe the walls with siding or edged boards, depending on your desire, and we can assume that the procedure for warming the wooden house outside the mineral wool is complete.

Helpful advice! Penophenol should be laid strictly in the horizontal direction, while leaving the joints 5 cm in such a way that there is a foil part outside.

Expanded polystyrene has an extremely low thermal conductivity, which makes it possible to effectively use it as a thermal insulation material, using for exterior wall cladding.

For the first time extruded polystyrene foam was used in the United States, where it immediately gained popularity due to its characteristics. Its production consists in mixing a special composition consisting of carbon dioxide and freon with granular polymer. The resulting mixture under the influence of high temperature is fed to a special apparatus, which is called an extruder. Its task is to foam the composition and to ensure high-quality mixing of all components.

The mixture obtained in the extruder is formed into plates that freeze to form a lightweight and durable insulating material. The advantages of such a technology of wall insulation with foam plastic on the outside, include low vapor permeability of the material, as well as durability and resistance to external factors.

According to the manufacturers, the operational life of this material can reach 50 years, if the installation technology has been observed. In terms of its structure, polystyrene foam is 90% composed of air, which is enclosed in cells.

Expanded polystyrene is always used for external wall insulation, since the material has a considerable volume, and the internal insulation of the rooms will lead to significant loss of free space. If we take into account, the standard thickness of polystyrene foam for wall insulation 80-100 mm or 30-40 mm, laid in two layers, then such loss of useful space inside the house will be quite noticeable.

In this case, one should not underestimate the effectiveness of this method, since by using this heat insulator, a saving of about 50% is achieved in paying for heating. Although one can not fail to notice a rather high price for work. Wall insulation foam board outside, taking into account all the necessary finishing work, will cost from 1300 rubles per 1 m ?.

Helpful advice! In order to achieve the desired effect, it is necessary to perform work at a temperature not lower than 5? С and as dry as possible.

Like any work related to surface warming, everything begins with the preparation and cleaning of the wall from dirt and any excess solution. Protruding reinforcement elements and simply protrusions that are not an architectural solution can interfere. When all the excess is removed, it is necessary to seal all cracks and crevices and prime the surface.

When preparation is completed, it is necessary to install vertical cuts. It is easiest to do this with the help of kapron cords, fixed with a pitch of 0.5-0.7 m. With their help, you can see if there are dips or bulges on the wall and, if necessary, add more glue. Sometimes you have to slightly change the shape of the plate, using a special grater.

Helpful advice! In order to make the end result look aesthetically pleasing, check each laid element with a building level.

The technology of thermal insulation of the facade of the penoplex provides that the fastening of the elements is made on a special adhesive mixture. It is prepared according to the instructions attached to it. It is important to use the prepared amount of the solution for 1.5 hours if the ambient temperature is not too high. In hot weather, this period is reduced to 40-60 minutes.

Glue is applied to the slab at the edges, as well as in five places in the middle, regardless of what thickness the penoplex is chosen for wall insulation. This ensures its secure attachment to the surface of the wall. If you have to fix the insulating material on a perfectly flat surface, then for applying the solution it is best to use a comb spatula.

If you need to put not one, but two layers of expanded polystyrene, laying should be done in such a way that the seams do not match. In addition, you will need to seal all the gaps between the plates, using small pieces of the same material or its liquid form. Foam for this purpose is not recommended. And if there are any discrepancies between the elements in the places where they should touch, then this can be eliminated with the help of the same grater.

Finally, mechanical insulation of insulation plates is also carried out in order to eliminate the risk of their detachment from the surface. At the rate of 5-6 fasteners per sheet, they are fixed with the help of dish-shaped dowels.

Unlike polystyrene foam, mineral wool and other popular heaters, the technology of spraying polyurethane foam involves a very complicated procedure associated with the use of expensive equipment. The fact is that in order for the coating to have the desired characteristics and to be resistant to external factors, a mixture of the components of the solution must be supplied under the influence of a very large pressure.

The fact that the external insulation of wooden houses significantly bypasses internal efficiency in terms of effectiveness has already been proven in practice. Although much, of course, depends on the correct selection of thermal insulation material, and on compliance with all the requirements of technology. Fortunately, the modern market is rich enough, and is able to offer buyers a wide choice of materials for thermal insulation of wooden houses.