The facade of the building requires a lot of attention. Beautiful veneer will make the house unique and highlight it among other buildings. Using metal siding under a tree for covering the house, you can upgrade the old facade, which has already lost its appearance, or to decorate a new house. Especially this method is suitable if it is not possible to use a real timber in construction. The main advantage is that you can veneer the facade with siding without using expensive tools.

Features and main disadvantages of metal siding under the tree

Construction companies offer a large number of materials that can be decorated and revetted facade. Choosing a metal siding under the timber, you can be sure that the sheathing will last a long time and will not require additional repair after a short period of time. The material is used not only in the construction of residential buildings, but also for industrial buildings.

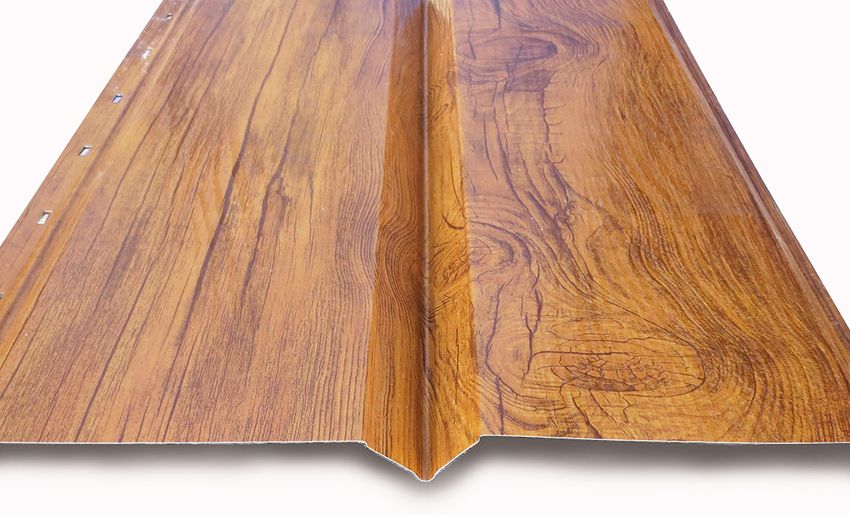

Iron siding is a galvanized sheet having a polymer coating, which can be painted to any structure. Very often sheets under wood are combined with metal siding under stone, which adds to the façade of unusualness and uniqueness, and at a distance it is difficult to distinguish the veneer from natural materials.

Metal siding for exterior is considered a convenient and easy-to-work material. Even without a construction experience, you can easily cope with the lining, watching educational videos and reading in detail with the instructions. You do not have to buy expensive tools. The buyer selects the material that suits him in color and structure of the picture. Siding for the facade is considered the best choice in terms of price – quality. The average price of metal siding under the log is 460 rubles per square meter.

Important! Since the building material is designed for exterior decoration, it is resistant to temperature changes, moisture, and also has a high wear resistance.

The main disadvantages of using building materials include its thermal conductivity and impressive sheet weight. If the roof is covered with siding, then in addition under it should be laid a layer of insulation, otherwise on the attic floor in the hot season will always be stuffy. If the house is covered with metal siding, then the facade tends to become very hot in the sun and radiate heat. In this case, in the intense heat as a result of contact, you can get a slight burn, so care must be taken when working with the material, and being close to it.

If you do the house trimming with metal siding, then such a facade will sustainably resist temperature drops and other external influences. Even if in winter the ambient temperature is constantly low, the material does not deform, does not lose color and shape. Due to the peculiarities of production, galvanized sheets are characterized by increased strength and resistance to point damage. Well-known manufacturers of metal siding under the log guarantee that the lining will last at least 50 years. Other material benefits include:

- ease of care. Siding is not required to be treated with special cleaning agents: any contamination is removed by the usual composition for washing dishes or windows;

- easy repair If a sheet has been deformed, you can try to restore the original shape or replace it with a new one;

- possibility to use everywhere. The material is not affected by fungus, moss or mold, and is also resistant to temperature extremes, so the installation of metal siding can be done in any climatic zone of Russia, regardless of humidity;

- fire safety. The houses in which cladding sheets of metal siding were used for brick or wood, are considered safe, because combustible or flammable substances are not used in the production of the material;

- long service life. Siding facades are resistant to the appearance of corrosion, the surface of sheets for a long time maintains brightness and color saturation, does not fade in the sun;

- universal size. Not only finished products are sold on construction sites, but there is also the possibility to order the required size of metal siding from the manufacturer;

- big choice. There are various colors of metal siding under the log and just under the natural wood;

- environmental friendliness. When heated, the sheets do not emit dangerous vapors that could affect human health;

- ease of installation. Sheets can be laid both vertically and horizontally.

Note! No smell should emanate from a building lined with metal siding.

Metal siding, imitating the structure of natural wood, began to be used no more than 10-15 years ago. In contrast to the natural material, the sheets do not require special treatment from the mite, moisture, they do not need to be impregnated with a special fire-fighting mixture. The life of metal sheets is higher than that of natural wood, and they retain their brightness for a very long time.

The dimensions of metal siding depend on whether this profile is vinyl or metal: the average width is 20 cm, thickness is 0.1 cm, and the length varies from 2 to 6 meters. There is an opportunity to choose a smooth or rough surface.

A detailed description of the material and its characteristics are presented in the table:

| Sheet options | Value |

| Thickness mm | 0.35–0.65 |

| Length, cm | ?400 |

| Width, cm | 20-25 |

| Weight 1 m?, Kg | ?3.5 |

| Coating thickness, micron | 25-200 |

| The thickness of the soil layer, microns | 5-8 |

| Optimum temperature of use? With | – 50 – +80 |

In the manufacture of blanks for siding used carbon steel alloy, while using cold rolled steel. Each sheet is top treated with a protective layer against corrosion. The drawing under the tree is applied either with a plastic film using Printech offset printing, or with a special sun-reflecting paint. Also, some manufacturers use their own paint, the composition of which is not disclosed. Depending on the type of material applied, the life of the building material is determined, which varies from 10-15 years to infinity.

There are various types of polymer coatings of metal siding sheets for exterior home, which affect the time of their service, which is clearly shown in the table:

| Type of coverage | Marking | Service life, years |

| Polyester | PE | ? 20 |

| Matte Polyester | REMA, PE matt | 15-20 |

| Plastisol | PVC-200 | ? thirty |

| Pural | Pural | ? thirty |

| Polyvinylidene fluoride (PVDF) | PVDF | ? 50 |

Siding panels are divided into categories depending on the design features and mounting methods:

| View | Special features |

| Perforated | Increased strength and resistance to temperature changes of the environment provides a vinyl base. Differs in high wear resistance |

| Ground floor | Sheets are characterized by a rectangular shape, they are connected at the joint zone. The dark-colored metal siding simulating a log that is resistant to high humidity is best suited |

| Facade | Mounted on the front of the building, has the largest selection of colors |

| Ceiling | Used not only for ceilings. Mainly used to sew irregularly shaped structures |

| Vertical | Sheet fastening is necessarily from top to bottom. |

| With insulation | It is made in the form of a cassette in which there is a heater between the layers of steel. The price of metal siding under a tree with a layer of insulation will be slightly higher than the cost of a regular sheet |

Originality will be given to a facade of the house by any siding – be it a metal siding under a stone or with the invoice under a bar or a tree. On the market you can buy metal siding and vinyl cladding, the difference of which is the composition of the sheets. Will help to understand which siding is better: metal or vinyl – customer reviews. It is especially important to get acquainted with the responses of those consumers whose house was cladding 5-10 years ago. In this case, focusing on the state of the sheets, it is easier to choose the manufacturer and determine the color.

The table presents the comparative technical characteristics of vinyl and metal siding:

| Characteristic | Metal | Vinyl |

| Surface finish texture | Without roughness. There are options for timber, log and brick | Smooth, with the invoice. The most popular options are natural wood, timber |

| Ease of installation | Easy to install, no special tools required. | |

| Environmental friendliness | In the production of siding these types of elements do not apply harmful substances | |

| Composition of the sheet | Cold rolled steel, aluminum | Polyvinyl chloride |

| Temperature at which it is recommended to carry out installation of metal siding,? С | Irrelevant | It is not recommended to install in a strong heat and when it is freezing over – 15 |

| The temperature range at which the building material can be operated? С | -40 – + 45 | – 50 – + 75 |

| Fire safety | Does not ignite, but loses its shape when exposed to high temperatures (over + 100? C) | Does not burn, begins to melt at a temperature? 500? C |

| Resistance to high humidity | Recommended for installation in conditions of any humidity. Immune to mold and mildew | |

| Surface treatment | No special treatment required. | |

| Possible shades | It is made in any color and imitates any other material: brick, log, natural stone | Produced only in pastel colors. It features a small selection of textures. |

| Durability | It is characterized by medium resistance. | It is highly resistant to mechanical damage. |

| The length of one sheet, m | ? four | ? 6 |

| Lifetime, years | ? 50 | |

Most often, the consumer prefers metal siding under a timber, which imitates with its surface a cut of oak, pine, walnut, alder, poplar, maple. Also, when choosing, it is necessary to correctly calculate the required volume of material, taking into account the fact that sheets are often overlapped, which means that in this case some part of the area is lost.

There are many formulas by which it is easy to calculate the volume of material depending on the area of the cladding and the peculiarities of installation, produced according to the principle of “lock to lock” or overlap. The price of metal siding for timber varies depending on the quality of the material used and starts from 300 rubles. for m ?.

Over the past few years, the most popular on the territory of Russia remains a shipboard board – metal siding, which looks like a board that has 2 parallel strips. The profile is made with a different coating, the color is uniform or has a stamping under the tree. Also received good reviews metal herringbone siding, in which the strips are angled. Designers do not recommend the use of such sheets for cladding large houses, they are best suited for compact single-storey cottages.

In order to better visualize the project, before buying it is recommended to look at how metal siding imitating a board, a stone or a tree looks like in a photo. Experts advise to pay attention to the acrylic metal siding for exterior home, which is characterized by greater resistance to sunlight, as well as less susceptible to mechanical and chemical damage.

The main producers with positive consumer reviews and approximate prices for their products are shown in the table:

| Siding type | Parameters (length X width X thickness), cm | The cost of one sheet, rub. |

| Cedral fiber cement | 360X19X1 | 950 |

| Holzplast Holzblock180 | 366X18X1,2 | 460 |

| Docke vinyl | 366X24X1,1 | 165 |

| FineBer Standard Plus Vinyl | 366X20.5X1.2 | 145 |

| Villed block house | 140X36X1 | 510 (m?) |

| “Karelian” block house | 360X24.4X1 | 220 |

| Docke double block house | 366X24X1 | 183 |

Some companies produce several types of siding. For example, the American manufacturer Grand Line manufactures stone siding, the cost of which is 600 rubles per square meter, metal siding under a tree – from 350 rubles per square meter. The most expensive is vinyl cladding material, the price of which reaches 800 rubles per square. Also, the presence of an anti-fossil lock affects the value increase. However, if in the construction region there are often heavy winds, it is better not to save on this, because it will be much more expensive to cover the roof.

Before you start to trim the house with metal siding, you need to purchase a grinder with spare discs, a saw and scissors for metal. Also need a screwdriver. To accelerate and facilitate the process will help screwdriver. If the house is large, either scaffolding or a ladder will be required, depending on the number of floors in the building. Other necessary tools:

- tape measure (laser is better);

- hammer;

- gon;

- level.

To buy the required amount of material, the buyer needs to know the area of the walls, the type of roof, the number of window and door openings. Given these indicators, the seller will be able to accurately calculate the desired amount. Before starting the installation, all the gaps and holes are sealed with cement mortar; the wall is cleaned of dirt and old paint. If the house is made of wood, the surface is treated with a mixture against the mite and fungus.

Important! Before you fix the sheets, you need to perform crates.

Briefly step by step instructions for mounting metal siding do it yourself:

- The volume of the required material is calculated taking into account the fixing features. In this case, the construction calculator will come to the rescue.

- Crate is hung.

- Fit the first siding strip with respect for the corners.

- The panels are fixed depending on the characteristics of the material, texture and method of installation.

- Niches are cut for windows and doors.

- Slopes, window sills, trim are fixed.

- The final level is set to the finishing plate and the final panel row.

It is strictly forbidden to fasten siding sheets to the wall, under them you need to put a galvanized profile, a profile – under drywall or wooden frame. The direction of the frame depends on the method of fastening the siding sheets: if you plan to mount them vertically, the crate is installed horizontally – and vice versa. More often panels under a siding are fixed horizontally.

Before mounting on the walls of the house in a circle spend a smooth closed loop. From this line, the minimum distance to the basement is found and, observing the corners, they draw another contour along which the starting bar will then lie down. It is necessary to draw strictly on the level, so that the panels lie flat. The parts of the batten are joined to each other using self-tapping screws for profiles.

Using a U-shaped mount (another name ES-clip or crocodile), mount the vertical guides. The use of such methods of fixation allows you to level the surface strictly on the level. Crate under the metal siding start to do from the corner of the building. The distance between the guides depends on the length of the wall, but it should not be less than 40-50 cm. It is important to understand that the frame is needed not only to fix the siding sheets, but also to provide ventilation and condensate drainage.

It is necessary to begin installation with a base drain, the upper edge of which is placed along the previously applied contour. This is done because the rigid structure is easier to position exactly than the starting bar, which is bent. After this, the corner profiles are fixed, rigidly fixed with screws, while holes are made in the upper part of the elements. Next, the screws will be mounted in the middle of the profile.

To mount metal siding start from the bottom row, locking the sheet in the starting plate. Each element is fixed on the frame separately. If it is necessary to change the size, a handsaw is used, with which the panel is either shortened or cut. For mounting siding used screws with a rubber washer, which are screwed on the edge of the sheets at least every 20 cm. In this way, and the remaining rows, placing between them butt strips.

Window bars or J-profiles are fixed so that the lower outer edge is 2 cm lower than the inner one. Doorways are also edged with J-profiles. Do you need to cut the corners of window and door elements to 45? or lay the top and side rails on top of each other. For mounting H-profiles you must use a level.

Important! When installing vertical elements, be sure to leave a gap of 0.6 cm to the eaves and basement, to prevent the bending of the planks during their expansion.

To beautifully arrange the internal and external corners of the building and hide the ends of the siding, use the corner strips. Ventilation panels – soffits – mounted along the eaves. The finishing bar is fixed under the roof, in the place where the planned covering area ends. Warming of the walls of aerated concrete or wood is optional, but the implementation of waterproofing is a prerequisite. The best insulation is provided by a moisture-windproof membrane, which is attached directly to the wall of the house.